Desalination and brackish water pumps work under harsh conditions—high salinity, abrasive particles, and constant pressure.

Reliable sealing is critical to prevent leaks, maintain efficiency, and reduce downtime.

텅스텐 카바이드 씰 링 are widely used in these systems because of their durability, 내식성, 그리고 긴 서비스 수명.

This article explains their advantages, applications, and best practices for decision-makers.

Why Desalination and Brackish Water Pumps Need Strong Seals

Prevent leaks → Protects expensive equipment and prevents contamination.

Maintain pump efficiency → Reliable seals reduce friction and energy waste.

Handle high salinity → Saltwater is corrosive to weaker materials.

Reduce downtime → Avoid unplanned maintenance and expensive repairs.

Protect the environment → Prevents saline leaks that could harm ecosystems.

텅스텐 카바이드 씰 링의 특성

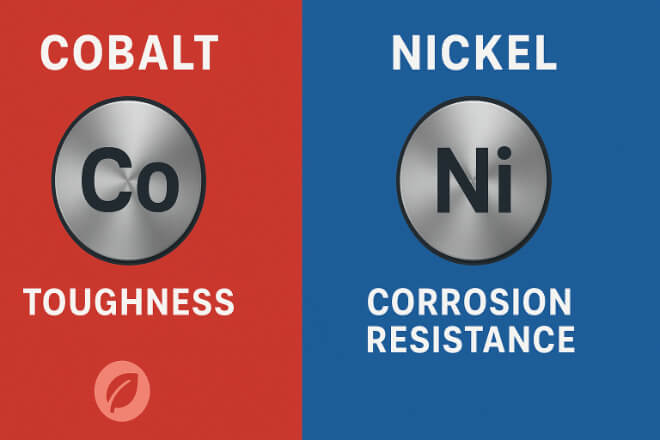

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its properties include:

다른 씰 재료에 비해 장점

| 특징 | 텅스텐 카바이드 | 세라믹 | 강철 |

|---|---|---|---|

| 내마모성 | Excellent for abrasives | 보통의 | 가난한 |

| 부식 저항성 | High (nickel grades) | Very Good | 낮은 |

| 강인함 | 높고 충격에 강함 | 낮음, 취성 | 보통의 |

| Thermal Performance | Excellent at high heat | 좋은 | 보통의 |

| Service Life | 오래 지속되는 | 보통의 | 짧은 |

Applications in Desalination and Brackish Water Pumps

텅스텐 카바이드 씰 링 다음에서 사용됩니다:

Reverse osmosis pumps → Provide reliable sealing under high pressure.

Intake and booster pumps → Handle seawater with abrasive particles.

Brackish water transfer systems → Prevent corrosion-related failures.

Energy recovery devices → Improve efficiency in desalination plants.

Marine-based desalination units → Operate reliably in offshore conditions.

비용 대 장기적 가치

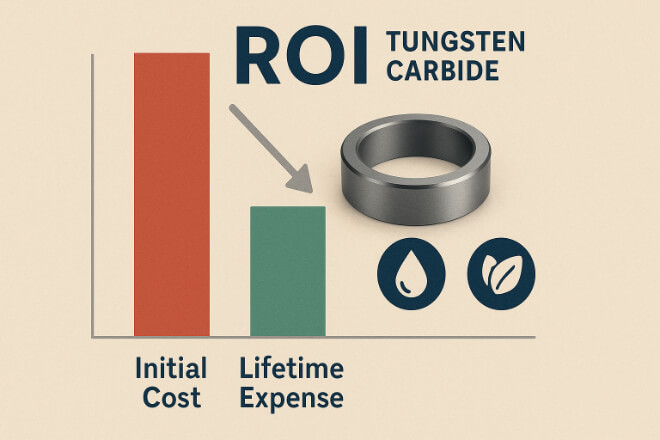

Although tungsten carbide seal rings may cost more upfront:

Reduce maintenance → Longer life means fewer replacements.

Improve ROI → Lower downtime increases production efficiency.

Protect equipment → Prevents costly damage to pumps and pipelines.

Support sustainability → Fewer replacements reduce waste and energy use.

Environmental and Safety Benefits

Leak prevention → Stops harmful saline discharge into the environment.

Recyclable material → Used rings can be recovered and reprocessed.

Energy savings → Efficient seals reduce energy consumption.

텅스텐 카바이드 씰 링 사용 모범 사례

올바른 바인더를 선택하세요 → Nickel-bonded for high salinity, cobalt-bonded for vibration.

Inspect seals regularly → Detect wear before leaks occur.

Ensure proper installation → Avoid misalignment and scratches.

경험이 풍부한 공급업체와 협력하세요 → Guarantee material quality and accurate specs.

Plan maintenance schedules → Reduce unplanned downtime.

의사결정자를 위한 주요 정보

Tungsten carbide seal rings are ideal for desalination and brackish water pumps.

Their durability, 내식성, and efficiency outperform ceramic or steel.

Higher upfront cost is offset by lower maintenance and downtime.

Using tungsten carbide supports environmental and operational goals.

결론

Desalination and brackish water systems need seals that can handle salt, pressure, and abrasion.

Tungsten carbide seal rings deliver superior performance, reduce leaks, and improve pump life.

For decision-makers, investing in tungsten carbide ensures reliable water supply, cost savings, and environmental protection.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.