Water pumps are the backbone of modern industry and infrastructure — from power plants and desalination systems to irrigation and wastewater facilities.

Yet, many pump failures begin with one small but important part: the bushing.

Bushings support rotating shafts, maintain alignment, and reduce friction. However, in water and slurry environments, they are constantly attacked by corrosion and erosion, leading to wear, vibration, and leakage.

That’s why tungsten carbide bushings have become a preferred choice. With their high 경도, 힘, 그리고 내식성, they provide a durable solution to extend pump life and reduce maintenance.

This article explains how tungsten carbide bushings solve corrosion and erosion challenges in water pumps, the science behind their durability, and where they deliver the most value.

Challenges in Water Pump Operation

Water pumps face multiple operating issues depending on the water source and fluid composition.

These problems accelerate wear on metal components and reduce service life.

Common challenges include:

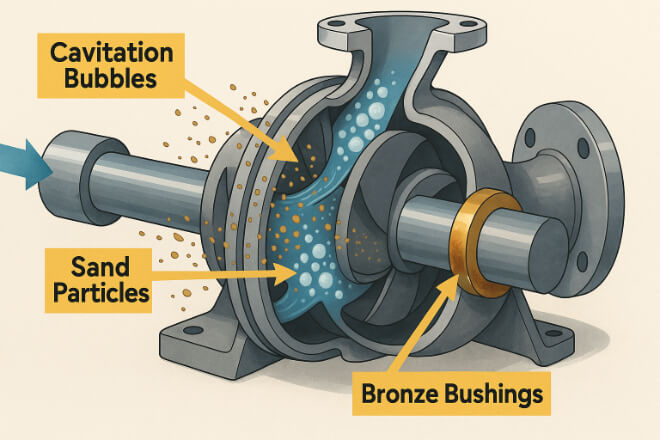

Corrosion: Chlorides, dissolved oxygen, and minerals attack metals.

Erosion: Suspended particles such as sand or silt act like abrasives.

Cavitation: Pressure drops cause vapor bubbles that collapse violently, damaging metal surfaces.

Unstable loads: Rapid start-stops or misalignment lead to uneven wear.

In untreated or seawater systems, these factors can destroy standard bronze or steel bushings in just a few months.

Why Choose Tungsten Carbide Bushings for Water Pumps

Tungsten carbide (WC) is a composite material made from tungsten particles bonded with a metallic binder (commonly cobalt or nickel).

It offers an unmatched balance of mechanical and chemical performance.

Key Benefits:

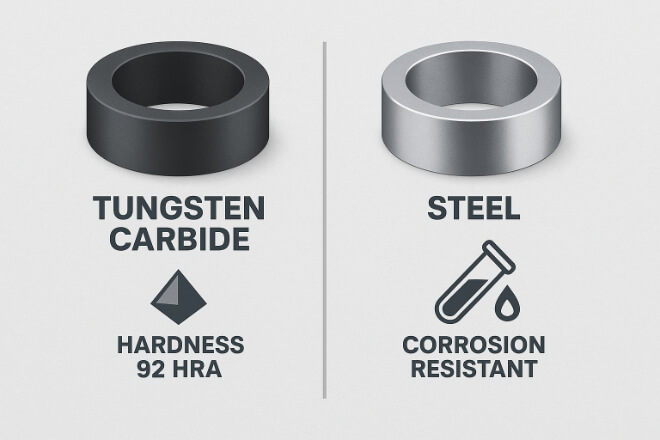

높은 경도 (88–92 HRA): Resists abrasive wear from particles.

훌륭한 내식성: Especially with nickel binders.

Low thermal expansion: Maintains dimensional accuracy.

High compressive strength (>4000 MPa): Handles pressure and misalignment.

These features make tungsten carbide bushings ideal for freshwater, seawater, and industrial process pumps.

Corrosion Resistance in Water and Seawater

| 재료 | 부식 저항성 | Typical Lifetime in Seawater |

|---|---|---|

| Bronze | Low – susceptible to pitting | 3–6 months |

| 스테인리스 스틸 | Moderate – prone to crevice corrosion | 1 year |

| Nickel-Bonded Tungsten Carbide | Excellent – inert to seawater and brine | 3–5 years |

Nickel-bonded grades form a stable passive layer that prevents oxidation and pitting in saltwater, chlorinated, or brackish conditions.

Even when exposed to high-chloride or oxygenated environments, carbide bushings retain their integrity, avoiding the surface rust common in stainless steel.

Erosion Resistance Against Abrasive Particles

Water pumps handling raw water or slurry face another major threat — erosion.

Small particles suspended in the fluid repeatedly strike surfaces, gradually removing material.

Tungsten carbide’s 경도 (close to that of diamond) provides outstanding protection. Its dense, non-porous structure resists micro-cutting and surface fatigue.

Example:

In a desalination feed pump transporting seawater with sand, bronze bushings showed severe wear within 8 months.

Replacing them with nickel-bonded carbide extended service life to over 3 years with minimal performance loss.

Applications in Different Water Pump Types

| Pump Type | Operating Condition | Bushing Function |

|---|---|---|

| Centrifugal Pump | Continuous flow, moderate abrasion | Shaft support and alignment |

| Submersible Pump | Immersed in water or seawater | Bearing and corrosion barrier |

| Slurry Pump | Heavy particles, high wear | Abrasion shield for shaft and seal areas |

Carbide bushings are especially useful in vertical turbine, cooling water, and wastewater pumps, where reliability and longevity are critical for continuous operation.

Binder Selection for Water Environments

| 바인더 유형 | 장점 | Best Used In |

|---|---|---|

| 코발트(Co) | High toughness and shock strength | Freshwater or low-chloride applications |

| 니켈(Ni) | 탁월한 내식성 | Seawater and brine systems |

Choosing the right binder is essential. While cobalt-bonded grades handle mechanical stress better, nickel-bonded bushings deliver the corrosion protection needed in seawater or chlorinated water applications.

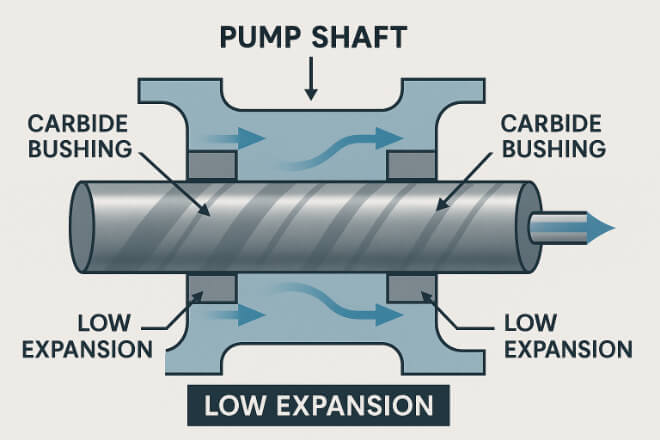

Dimensional Stability and Alignment

Water pumps often experience temperature and pressure changes. Poorly made bushings expand unevenly, causing misalignment and bearing failure.

Tungsten carbide’s low coefficient of thermal expansion (~4.5 × 10⁻⁶ /K) keeps it dimensionally stable, maintaining shaft alignment even under fluctuating loads.

This stability ensures smooth rotation, reduced vibration, and consistent flow performance over time.

Surface Finish and Efficiency

A finely polished bushing surface is critical in minimizing friction and improving hydraulic efficiency.

High-quality tungsten carbide bushings are precision-lapped to Ra 0.04–0.05 µm, providing a near-mirror finish.

This smoothness reduces turbulence and fluid shear, which helps:

Improve energy efficiency

Lower operating temperature

Extend seal and bearing life

Many modern desalination and power-plant pumps rely on this ultra-smooth surface to sustain long-term performance.

Maintenance and Life-Cycle Cost

| 재료 | Average Service Life | Maintenance Frequency | Overall Cost Efficiency |

|---|---|---|---|

| Bronze | 6–12 months | 높은 | 낮은 |

| 스테인리스 스틸 | 1–2 years | 중간 | 보통의 |

| 텅스텐 카바이드 | 3–5 years | 낮은 | 높은 |

Although tungsten carbide bushings cost more initially, they drastically lower maintenance costs and downtime.

In large water treatment or seawater intake systems, this leads to savings of 40–60 % over the equipment’s lifetime.

결론

For water pumps operating in harsh, corrosive, or abrasive environments, tungsten carbide bushings offer a proven solution.

Their superior hardness, corrosion resistance, and stability make them essential for achieving long service life and reliability in desalination, wastewater, and industrial systems.

By investing in carbide bushings, decision-makers can significantly reduce maintenance downtime, protect rotating assemblies, and improve long-term performance — ensuring reliable water flow and lower total cost of ownership.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.