텅스텐 카바이드 부싱 are known for their 경도 그리고 내마모성, making them vital in pumps, compressors, and high-load rotating systems.

However, corrosion and pitting remain two major threats that reduce service life — especially in chemical, marine, or wet process environments.

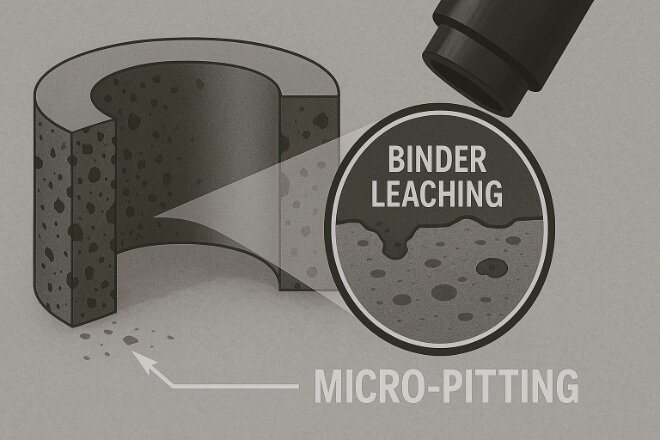

If corrosion is left unchecked, the binder phase (nickel or cobalt) begins to dissolve, leading to loss of strength, surface roughness increase, and micro-pitting.

Understanding the causes and applying proper prevention techniques helps ensure your tungsten carbide bushings deliver maximum durability and performance.

Why Corrosion and Pitting Occur

Even though tungsten carbide is extremely hard, it is not fully immune to chemical attack. The metallic binder phase is often the weak point.

When exposed to aggressive fluids or electrolytes, the binder (especially cobalt) can oxidize or dissolve — allowing corrosive media to penetrate the carbide grain boundaries.

Common Triggers of Corrosion and Pitting

Acidic or alkaline fluids in chemical processing

Saltwater exposure in marine and offshore systems

High-temperature oxidation in power plants

Residual stress and microcracks that trap corrosive media

Once pitting starts, it grows deeper with time, eventually leading to bushing failure, shaft wear, or fluid leakage.

Step 1: Select the Right Binder Type

Choosing the proper binder is the first defense against corrosion.

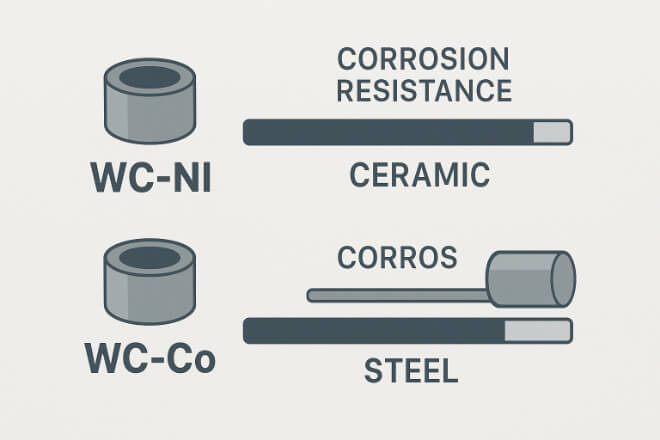

Cobalt-bonded tungsten carbide performs well in neutral or dry environments, while nickel-bonded tungsten carbide offers better protection in corrosive or acidic fluids.

| 바인더 유형 | 일반적인 사용 | 부식 저항성 | Comments |

|---|---|---|---|

| Cobalt Binder (WC-Co) | General machinery and dry environments | 보통의 | Prone to binder leaching in acidic media |

| Nickel Binder (WC-Ni) | Chemical and marine applications | 높은 | Better protection against corrosion and oxidation |

| Ni-Cr Binder | Extreme chemical and wet gas services | 매우 높음 | Chromium improves passive layer protection |

Tip: For seawater or acid-containing fluids, always select a nickel-based binder or grades containing chromium, which forms a stable oxide film to resist corrosion.

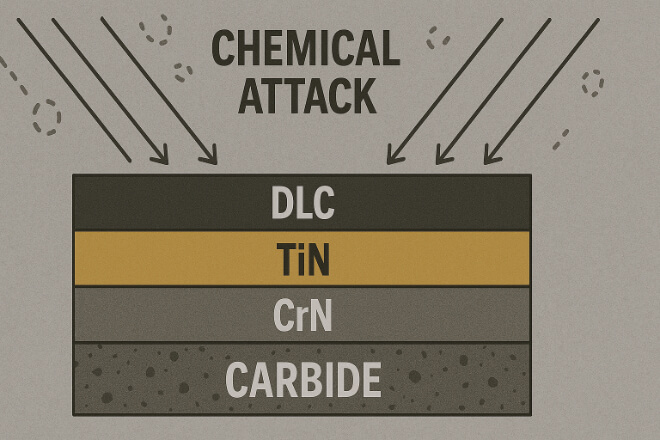

Step 2: Apply Protective Coatings

Coatings can greatly improve the chemical resistance of tungsten carbide bushings.

일반적인 코팅은 다음과 같습니다.

TiN (Titanium Nitride): Increases 경도 and corrosion protection.

CrN (Chromium Nitride): Offers strong oxidation resistance.

DLC (Diamond-Like Carbon): Reduces friction and prevents pitting initiation.

These coatings create a barrier between the fluid and the tungsten carbide surface, extending component life in harsh service.

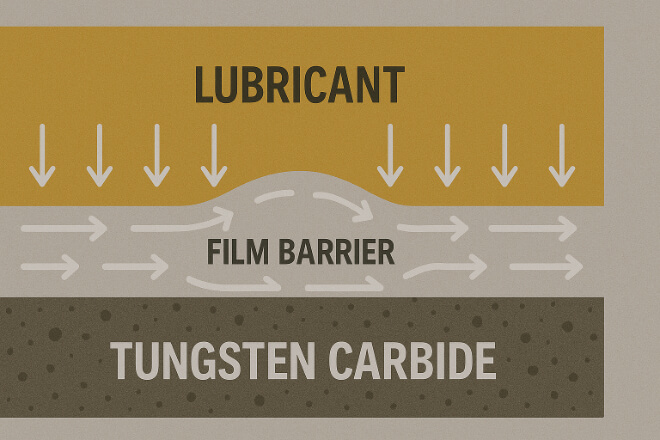

Step 3: Maintain Proper Lubrication

Inadequate lubrication accelerates both wear and corrosion. When the surface runs dry, microcracks appear, allowing corrosive fluids to enter.

Recommendations:

Use filtered, non-reactive lubricants.

Maintain a steady film thickness between the shaft and bushing.

Check lubricant pH compatibility with binder type.

Proper lubrication not only reduces friction but also isolates the bushing surface from corrosive environments.

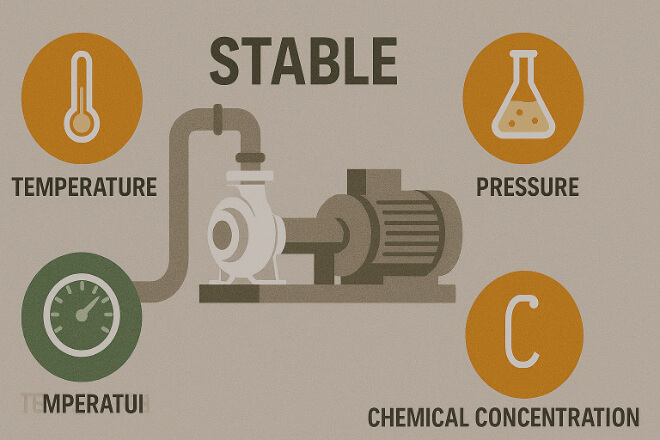

Step 4: Control Operating Environment

Temperature, pressure, and chemical concentration all influence corrosion rate. To extend service life:

Keep operating temperatures below 450°C (for WC-Ni).

Avoid rapid temperature cycling, which causes stress.

Ensure system flushing to remove stagnant fluids.

Step 5: Avoid Galvanic Corrosion

Galvanic corrosion occurs when tungsten carbide contacts dissimilar metals in a conductive fluid.

This is common in pump assemblies where the bushing interfaces with stainless steel or bronze housings.

| 상태 | Corrosion Risk | Prevention Method |

|---|---|---|

| Tungsten carbide against stainless steel | 중간 | Use isolating gasket or coating |

| Tungsten carbide against bronze | 높은 | Electrically insulate or use nickel-coated interface |

| Tungsten carbide against ceramic | 낮은 | Preferable for chemical or seawater systems |

Electrical isolation using non-conductive spacers or surface coatings can stop galvanic reaction and preserve the carbide surface.

Step 6: Regular Cleaning and Inspection

Deposits, salts, or corrosive residues often remain on the surface after operation.

Regular cleaning prevents localized corrosion and helps detect early-stage pitting.

Best practices:

Clean with non-acidic solvents or mild alkaline detergents.

Avoid mechanical scraping tools that may damage coatings.

Use magnification to check for micro-pits or color changes.

Perform a visual and dimensional inspection every 3–6 months depending on the fluid type.

Step 7: Store Bushings Properly

Improper storage can also cause corrosion, especially in humid warehouses or near chemical fumes.

이를 방지하려면:

Store bushings in dry, temperature-controlled areas.

Use anti-corrosion wrapping or desiccant bags.

Avoid contact with dissimilar metals during storage.

Proper storage ensures bushings remain ready for service without oxidation or binder attack.

Step 8: Consider Material Pairing

Tungsten carbide bushings often run against different shaft materials or sleeves. Choosing a compatible pairing minimizes both wear and corrosion.

Recommended pairings:

WC-Ni vs. Ceramic: Excellent 내식성 in chemical plants.

WC-Co vs. Hardened Steel: Good for mechanical loads but avoid wet acids.

WC-Ni vs. Silicon Carbide: Excellent for seawater and brine service.

결론

Corrosion and pitting can shorten the life of tungsten carbide bushings, but both can be prevented with proper design, material choice, and maintenance.

By using nickel-binder grades, applying protective coatings, and maintaining a stable, clean operating environment, industries can significantly increase reliability and uptime.

Preventive care is always more cost-effective than reactive replacement — ensuring safer, longer-lasting operation.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.