When choosing tungsten carbide bushings, many buyers focus on binder percentage or overall hardness.

However, one hidden factor defines how strong, tough, and reliable the part truly is — grain size.

The grain size of tungsten carbide controls how the bushing reacts under stress, friction, and temperature.

A change as small as a few microns can shift its performance from brittle to durable, or from weak to highly 내마모성.

This article explains how grain size works, how it is controlled during manufacturing, and how it influences the overall strength and service life of tungsten carbide bushings in industrial applications.

Understanding Tungsten Carbide Microstructure

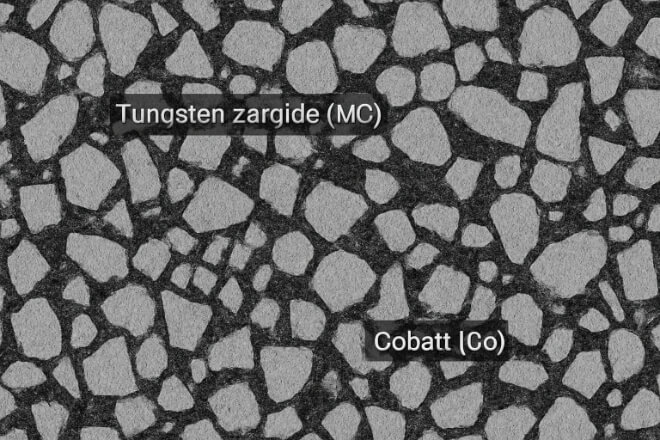

Tungsten carbide bushings are not made from a single solid metal. They are composite materials consisting of two key parts:

Tungsten Carbide (WC) grains – extremely hard ceramic crystals.

Binder metal (Cobalt or Nickel) – soft metallic phase that holds the grains together.

Under a microscope, tungsten carbide looks like small gray grains surrounded by a lighter metallic binder.

The size and uniformity of these grains determine mechanical properties such as 경도, 강인함, and crack resistance.

What Is Grain Size and How Is It Measured?

Grain size refers to the average diameter of tungsten carbide particles within the composite. It is typically measured in micrometers (µm) and classified as follows:

| 범주 | Grain Size (µm) | Key Characteristics | 일반적인 응용 프로그램 |

|---|---|---|---|

| 서브마이크론 | 0.2 – 0.8 | High hardness and wear resistance | Precision tools, bushings in abrasive media |

| 괜찮은 | 0.8 – 1.5 | 균형 잡힌 경도와 인성 | General-purpose wear components |

| 중간 | 1.5 – 3.0 | Improved impact resistance | Pump sleeves, compressor bushings |

| 조잡한 | 3.0 – 5.0 | High toughness, lower hardness | Heavy-duty impact or shock environments |

The smaller the grains, the harder and denser the material becomes.

However, finer grains also make the carbide more brittle — which is why proper grain size selection is crucial for each application.

How Grain Size Affects Bushing Strength

The relationship between grain size and strength is governed by a principle known as the Hall–Petch effect.

In simple terms, smaller grains block crack propagation, making the material stronger and more resistant to wear.

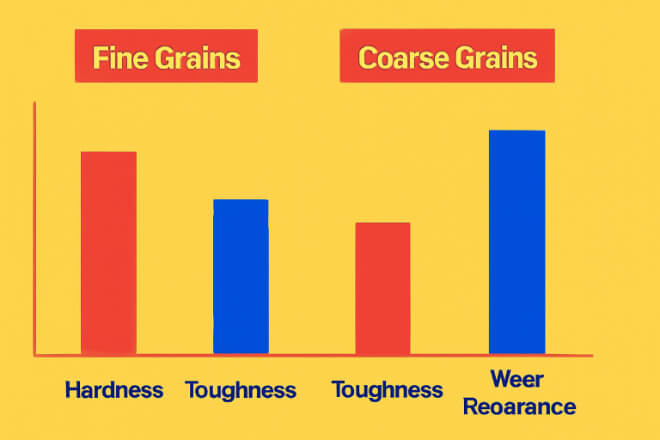

1). 경도

Finer grains increase hardness because they restrict dislocation movement.

For tungsten carbide, hardness can rise from 1,200 HV to 1,900 HV as grain size decreases from 3 µm to 0.5 µm.

2). 강인함

Coarser grains absorb impact better, preventing brittle fractures.

For example, a 4 µm grain WC may have 20% higher fracture toughness than a 0.5 µm grade.

3). Compressive Strength

Tungsten carbide’s compressive strength (5,000–7,000 MPa) changes slightly with grain size — finer structures hold up better against surface wear.

4) 열 안정성

Finer grains are more stable at high temperatures but may sinter or oxidize faster without proper binder control.

The challenge is to balance hardness and toughness depending on service conditions.

Grain Size Control During Manufacturing

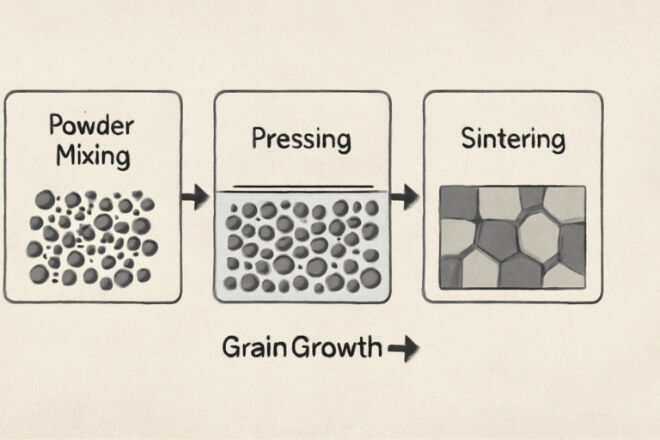

Manufacturers control grain size through several key production steps:

1). Powder Preparation:

Starting powders are milled to achieve the target particle size.

Additives such as VC (vanadium carbide) or Cr₃기음₂ (chromium carbide) are used to inhibit grain growth.

2). Pressing:

Powders are compacted under uniform pressure.

Uneven pressure may cause density variation and grain clustering.

3). Sintering:

Performed at 1350–1500°C in vacuum or protective gas.

Grain size grows during sintering — temperature and time are strictly controlled.

Fine-grained grades require shorter sintering times to prevent coarsening.

4). Post-Sinter Finishing:

Grinding and lapping remove surface irregularities while maintaining microstructure integrity.

Microstructure Comparison: Fine vs. Coarse Grain

The microstructure directly reveals how grain size affects physical performance.

| 재산 | Fine-Grained WC | Coarse-Grained WC |

|---|---|---|

| 경도 | Very high (≥1800 HV) | Moderate (1200–1400 HV) |

| 강인함 | Moderate; can crack under shock | Excellent; absorbs impact well |

| 내마모성 | Excellent, especially in abrasion | Good, but lower surface life |

| Thermal Crack Resistance | 보통의 | 높은 |

| 응용 프로그램 | Seals, precision sleeves, fine wear parts | Mining, heavy-duty pumps, impact zones |

The right choice depends on whether your system values abrasion control or shock resistance more.

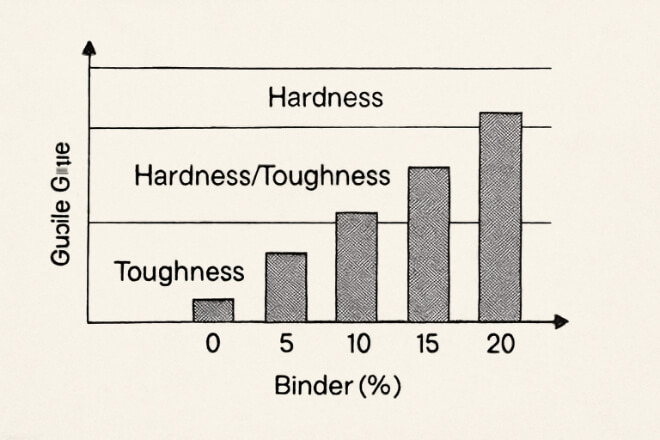

Grain Size and Binder Content Relationship

Grain size and binder content work together to define final mechanical properties.

Smaller grains require slightly more binder to maintain 강인함, while coarser grains can work with less binder.

For fine-grained carbides, binder typically ranges from 8–12% cobalt.

For coarse-grained carbides, binder content can drop to 6–8%.

This balance keeps the composite dense and prevents brittleness or porosity.

Applications and Grade Selection

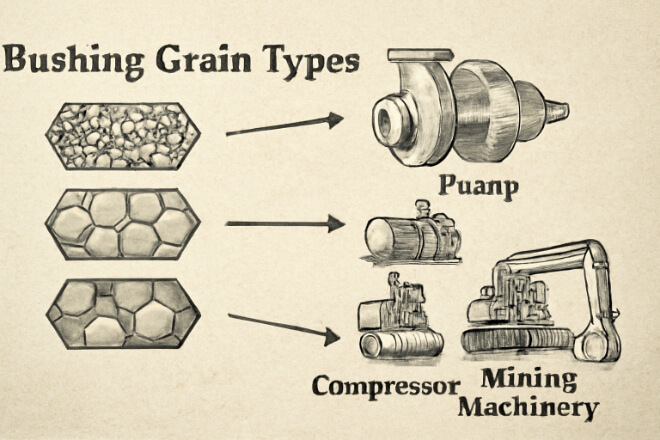

Choosing the correct grain size for tungsten carbide bushings depends on the operating conditions:

High wear, low shock (slurry pumps, chemical mixers): Fine-grained WC with Ni or Co binder.

Moderate wear, moderate load (compressors, blowers): Fine-to-medium grains (1–2 µm).

High impact or misalignment (mining, drilling): Coarse-grained WC (3–5 µm).

Custom bushing designs often mix two types of grain zones — for example, fine-grain on the surface for wear resistance and coarse-grain in the core for strength.

결론

Grain size defines how tungsten carbide bushings balance hardness, toughness, and stability.

Fine grains deliver unmatched wear resistance, while coarse grains ensure mechanical resilience under impact or vibration.

For decision-makers, understanding this trade-off is key to selecting the optimal grade for your application.

Working with a supplier who can control grain size precisely during manufacturing ensures longer service life, less downtime, and better performance of your equipment.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.