Additive manufacturing (AM), also known as 3D printing, has revolutionized several industries, including the production of tungsten carbide bushings.

Tungsten carbide is already known for its high 내마모성, strength, and durability, making it ideal for industrial applications.

However, traditional manufacturing methods for tungsten carbide bushings are often limited by complexity, cost, and production time.

With additive manufacturing, we can now produce bushings with more precise geometries, faster turnaround times, and lower material waste, opening up new possibilities for improving performance and reducing costs.

This article will explore how additive manufacturing is shaping the future of tungsten carbide bushing production, its benefits, challenges, and what lies ahead for the industry.

What is Additive Manufacturing and How Does It Work?

Additive manufacturing is a process where material is deposited layer by layer to build a part, as opposed to subtractive methods like milling or machining.

In the case of tungsten carbide bushings, this technology allows for highly customized designs and complex geometries that are difficult to achieve with traditional techniques.

Key Additive Manufacturing Techniques:

Laser Powder Bed Fusion (LPBF): A laser is used to fuse 텅스텐 카바이드 분말 into solid layers, enabling precise control of the material properties.

Selective Laser Sintering (SLS): This technique uses a laser to heat powdered material, allowing it to bond and create a solid structure.

With these methods, manufacturers can produce bushings with enhanced material properties, complex shapes, and reduced waste.

How Additive Manufacturing Improves Tungsten Carbide Bushing Production

The integration of additive manufacturing in tungsten carbide bushing production brings several key advantages over traditional methods. Here are some of the ways AM improves the production process:

1). Precision and Customization

One of the greatest advantages of additive manufacturing is the ability to create highly customized bushings tailored to specific needs.

Manufacturers can design bushings with complex internal geometries or precise fits, ensuring optimal performance in specialized applications.

1.1). Examples of Customization:

Bushings with internal cooling channels

Bushings with specific tolerances for particular machinery

Optimized designs for less material waste and higher strength

1.2). Why is this important?

Additive manufacturing allows the precision to optimize the performance of tungsten carbide bushings in environments that require customized solutions for 내마모성 or load-bearing capacities.

2). Faster Production and Prototyping

In traditional manufacturing, producing a tungsten carbide bushing often requires long lead times for tooling and molds.

With AM, rapid prototyping is possible, allowing manufacturers to quickly iterate on designs and bring products to market faster.

2.1). Benefits of Faster Production:

Reduced time to market

Quicker testing and validation

Ability to adapt to changes in design without significant delays

AM allows for faster, more agile production, reducing the time between conceptualization and implementation.

3). Material Efficiency and Reduced Waste

AM uses only the material required for the part, significantly reducing the material waste that typically occurs during machining.

In traditional manufacturing methods, excess material is often cut away, leading to material loss and higher production costs.

3.1). Why is this important?

In industries where tungsten carbide is a costly material, reducing waste helps save money and make the production process more environmentally friendly.

Benefits of Additive Manufacturing for Tungsten Carbide Bushings

1). Improved Durability and 내마모성

텅스텐 카바이드 부싱 are known for their durability and wear resistance, but AM allows manufacturers to optimize these properties further.

By controlling the material distribution and geometry during the printing process, bushings can be made even more resistant to wear and abrasion, enhancing their lifespan.

1.1). Applications:

Mining equipment

Heavy-duty machinery

Industrial pumps and valves

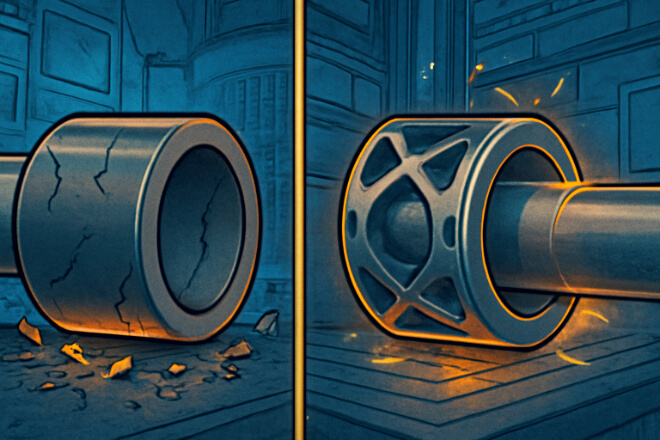

2). Complex Geometries for Better Performance

AM enables the production of complex shapes that are difficult or impossible to create with traditional manufacturing methods.

For tungsten carbide bushings, this means the ability to create lighter, more efficient, and stronger parts that can perform better under specific conditions.

2.1). Examples of Complex Geometries:

Bushings with internal cooling channels

Optimized load distribution geometries

More compact designs with better performance

3). Cost-Effective for Low-Volume Production

For industries that require small batches of highly specialized parts, additive manufacturing can be a more cost-effective solution compared to traditional methods, which require extensive tooling and setup costs.

3.1). Why is this important?

For low-volume production or rapid prototyping, AM allows companies to produce high-quality tungsten carbide bushings without the high overhead costs associated with traditional manufacturing.

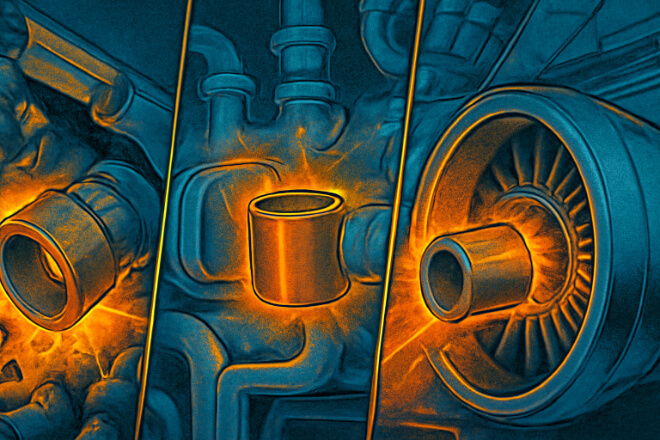

Applications of Additive Manufacturing in Tungsten Carbide Bushings

Tungsten carbide bushings produced using additive manufacturing are finding increasing applications across various industries.

Here are some key sectors where AM is having a significant impact:

1). 채광 and Heavy Machinery

In the mining industry, abrasive wear is a constant challenge for bushings and other machinery components.

AM allows for the production of custom tungsten carbide bushings that are optimized for 내마모성 and high performance in high-stress applications.

1.1). 예:

Drilling equipment

Conveyor systems

Crushers and mills

2). 석유 및 가스 산업

Additive manufacturing is helping the oil and gas industry produce parts that can withstand the extreme pressure, temperature, and chemical exposure common in downhole operations.

AM allows for the creation of customized bushings that meet these demanding conditions.

2.1) 예:

Downhole drilling equipment

Pumps and valves

Pressure vessels

3). 항공우주 and High-Performance Applications

In aerospace, precision and lightweight components are essential.

AM is being used to produce high-performance tungsten carbide bushings with complex internal structures, reducing weight while maintaining strength and wear resistance.

3.1). Examples:

Aerospace engines

Landing gear

Turbine components

Challenges of Additive Manufacturing in Tungsten Carbide Bushing Production

Despite the numerous benefits, additive manufacturing for tungsten carbide bushings is not without challenges.

1). Material Limitations

While additive manufacturing allows for intricate designs and customization, working with tungsten carbide in AM still presents challenges.

Tungsten carbide is difficult to print due to its 경도 and the need for high-density materials.

1.1). Challenges:

Limited availability of 텅스텐 카바이드 분말 suitable for AM

The difficulty of achieving high-밀도 parts without compromising material properties

2). Post-Processing Needs

After additive manufacturing, tungsten carbide bushings often require post-processing to achieve the desired surface finish, density, and mechanical properties.

2.1). Challenges:

Time-consuming and costly post-processing steps

Ensuring parts meet 강인함 and wear resistance requirements

결론

Additive manufacturing is shaping the future of tungsten carbide bushing production by offering faster production times, customization, and the ability to produce more complex designs.

While challenges remain, such as material limitations and post-processing requirements, the potential benefits of AM—particularly in industries like mining, oil and gas, and aerospace—make it an exciting avenue for innovation.

As technology continues to improve, additive manufacturing will play an increasingly important role in the production of high-performance tungsten carbide bushings, meeting the growing demand for customized and durable parts across various sectors.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.