텅스텐 카바이드 부싱 are known for their outstanding 내마모성 and strength, making them ideal for a wide range of industrial applications.

However, like all materials, tungsten carbide has temperature limits that must be considered to ensure optimal performance.

Understanding these temperature limits is crucial for industries such as 채광, 석유와 가스, 그리고 항공우주, where bushings are often subjected to extreme conditions.

This article will explore the temperature limits for tungsten carbide bushings, factors that affect their performance at high temperatures, and best practices for maximizing their service life.

What is Tungsten Carbide and Why Temperature Matters?

Tungsten carbide (WC) is a highly durable material made by combining tungsten and carbon.

뛰어난 것으로 알려져 있습니다 경도 and resistance to abrasion, it is widely used in bushings, bearings, and other components that endure high-stress environments.

1). How Temperature Affects Tungsten Carbide Bushings

Like all materials, tungsten carbide’s properties are influenced by temperature.

As the temperature increases, the material experiences thermal expansion, and at certain high temperatures, its strength and hardness can begin to degrade.

This is why understanding the temperature limits is critical for ensuring the reliability and longevity of tungsten carbide bushings.

At low temperatures: Tungsten carbide maintains its hardness and strength but may become more brittle and susceptible to fractures under shock loading.

At high temperatures: Tungsten carbide experiences softening, leading to reduced 내마모성 and potential failure of the bushing.

Temperature Limits for Tungsten Carbide Bushings

Tungsten carbide is capable of withstanding high temperatures, but it is not immune to heat. Typically, tungsten carbide bushings are used in service within the following temperature ranges:

1). Typical Service Temperature Range for Tungsten Carbide

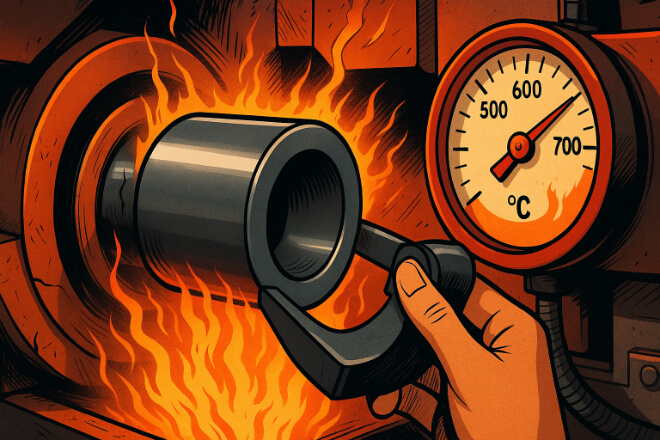

The typical service temperature for tungsten carbide bushings in industrial applications ranges from -100°C to 700°C.

Within this range, tungsten carbide retains its mechanical properties, making it ideal for most high-performance applications.

Optimal Service Temperature: 20°C to 500°C

At temperatures within this range, tungsten carbide exhibits excellent wear resistance and strength, maintaining its shape and durability.

High-Temperature Threshold: 500°C to 700°C

At these elevated temperatures, tungsten carbide can still perform well but may experience some softening and reduced 내마모성.

The material begins to lose some of its hardness and strength, which may affect its performance in high-stress environments.

2). Temperature Beyond the Limit: Effects on Tungsten Carbide

When temperatures exceed 700°C, tungsten carbide can undergo significant changes, resulting in a loss of its mechanical properties. At higher temperatures:

Above 700°C: Tungsten carbide begins to soften, losing its wear resistance and structural integrity.

Above 1000°C: The material may begin to degrade, leading to cracks and potential failure under stress.

In extreme cases, binder materials (such as cobalt or nickel) used in tungsten carbide may start to degrade, which accelerates wear and loss of material properties.

Factors Affecting Temperature Resistance in Tungsten Carbide Bushings

The temperature limits of tungsten carbide bushings can be affected by several factors, including:

1). Binder Material Type

Tungsten carbide is typically bound with metals like cobalt or nickel. These binders help enhance the material’s 강인함 and make it easier to machine.

However, the melting point of the binder material is lower than that of tungsten carbide, which can cause the bushing to lose its strength at lower temperatures.

Cobalt-bonded tungsten carbide: Typically can handle temperatures up to 600°C without significant degradation.

Nickel-bonded tungsten carbide: Offers slightly better performance at higher temperatures, up to 700°C.

2). Microstructure and Grain Size

The grain size of tungsten carbide can also influence its temperature resistance.

Finer grain sizes offer better 내마모성 and can help maintain structural integrity at higher temperatures.

On the other hand, larger grain sizes might result in lower strength at high temperatures.

Fine-grain tungsten carbide: Exhibits better performance under high temperatures due to more uniform material distribution.

Coarse-grain tungsten carbide: May be more prone to thermal degradation at elevated temperatures.

3). Environmental Factors

The operating environment plays a critical role in determining the temperature limits of tungsten carbide bushings.

For example, the presence of oxidizing agents or abrasive materials can cause accelerated degradation when exposed to high temperatures.

In environments with extreme heat cycling or high differential pressures, the bushing may experience thermal fatigue, which can lead to cracks and premature failure.

- Example: 항공우주 engines and high-pressure pumps expose bushings to both high temperatures and extreme operating conditions, requiring careful consideration of the material properties and temperature resistance.

Best Practices for Handling High-Temperature Applications

While tungsten carbide bushings can withstand high temperatures, it is important to follow best practices to maximize their service life in high-temperature environments:

1). Select the Right Binder Material

For applications that require resistance to higher temperatures, consider using nickel-bonded tungsten carbide, which offers better performance at higher temperatures compared to cobalt-bonded alternatives.

Choosing the correct binder material ensures that the bushing maintains its strength and durability.

2). Monitor Operating Temperature

Regularly monitor the operating temperature of machinery to ensure that the bushings are not exposed to temperatures beyond their limits.

Temperature sensors can provide real-time data, allowing for adjustments to avoid exceeding the safe temperature range.

3). Use Thermal Management Solutions

In some high-temperature applications, it may be necessary to implement cooling solutions to maintain the temperature of the bushings within a safe range.

Lubrication systems or cooling channels can help prevent overheating, ensuring that the tungsten carbide bushings perform optimally.

4). Regular Inspection and Maintenance

Regular inspection and maintenance of equipment can help detect early signs of thermal degradation or wear.

Check for signs of cracking, misalignment, or distortion in the bushings, which could indicate that the material is nearing its temperature limits.

결론

Tungsten carbide bushings are known for their exceptional durability and wear resistance, but their performance can be significantly impacted by temperature.

Understanding the temperature limits of tungsten carbide and the factors that affect its high-temperature performance is crucial for ensuring the reliability and longevity of machinery.

By selecting the right binder material, monitoring operating temperatures, and implementing thermal management solutions, companies can optimize the performance of tungsten carbide bushings in high-temperature applications.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.