Bearing clearance is one of the most important factors in the performance of tungsten carbide bushings.

If the clearance is too tight or too loose, problems such as friction, vibration, heat, noise, or even full pump failure can occur.

This article explains the common causes of clearance problems, how to detect them, and the best ways to fix and prevent them in pumps, compressors, and other rotating equipment.

Why Correct Clearance Matters

Tungsten carbide bushings are used because they provide strength, 경도, and stability under high load. But they can only work correctly when the bearing clearance is within the design range.

1). If clearance is too small

Excessive friction

과열

Risk of seizing

High shaft wear

2). If clearance is too large

Shaft instability

진동

Noise

Premature bushing wear

Poor sealing performance

3). Typical Clearance Ranges

These are general values used in many industrial pumps:

| Pump Type | Recommended Clearance | Risk if Below Range | Risk if Above Range |

|---|---|---|---|

| Vertical turbine pump | 0.15–0.25 mm | Friction, heat | Vibration, wobble |

| Centrifugal pump | 0.10–0.20 mm | Seizure | Noise, instability |

| High-speed pump | 0.05–0.12 mm | Rapid failure | Seal leakage |

Correct clearance ensures smooth rotation, long service life, and reduced maintenance costs.

Common Causes of Incorrect Clearance

When clearance is not correct, the root cause usually comes from one of the following issues.

1). Manufacturing tolerance errors

Bore diameter too small or too large

Shaft size variation

Incorrect roundness

2). Thermal expansion

High temperatures cause the shaft to expand

Bushing expands less because carbide has a different thermal expansion rate

Clearance becomes too small during operation

3). Misalignment

Shaft not centered

Housing not straight

Pump and motor misaligned

4). Wear from dirty or abrasive fluids

Particles entering the bearing can:

Increase clearance

Score the surface

Damage roundness

5). Poor lubrication or dry running

Without proper fluid film, both the shaft and bushing wear faster.

Detecting Clearance Problems Early

Early detection is the best way to avoid serious equipment failure.

1). Key Warning Signs

| Sign | Likely Cause | Too Small Clearance | Too Large Clearance |

|---|---|---|---|

| High temperature | Friction or lack of lubrication | Very likely | Rare |

| 진동 | Shaft instability | Possible | Very likely |

| Noise | Rubbing, wobble, or contact | Likely | Likely |

2). Other signs include

Shaft contact marks

Uneven wear

Changes in pump efficiency

Frequent shutdown alarms

These symptoms usually appear long before total failure.

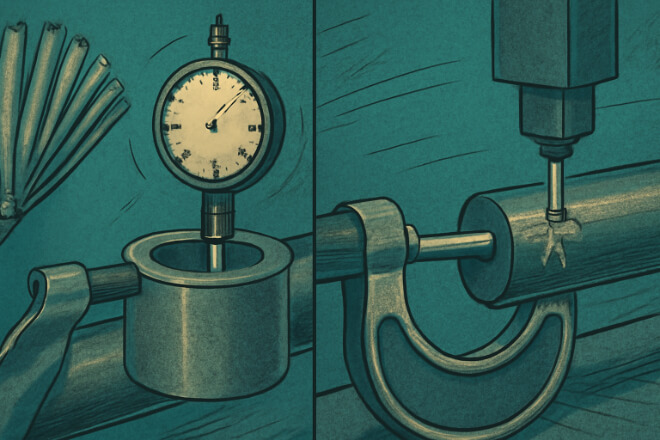

How to Measure Bearing Clearance Accurately

To troubleshoot clearance problems, accurate measurements are essential.

1). Tools Commonly Used

Feeler gauge

Bore gauge

마이크로미터

Dial indicator

CMM(좌표측정기)

2). Direct Clearance Measurement Methods

Measure shaft OD and bushing ID: Clearance = ID – OD

Use feeler gauge between shaft and bushing: Works well for large bearings.

Use CMM for precision-grade pumps: Very accurate for high-speed systems.

3). Important Notes

Always measure at room temperature

Measure in multiple directions (X, Y, and angular)

Check for out-of-round errors

Compare to engineering drawing values

Solving Too-Small Clearance Problems

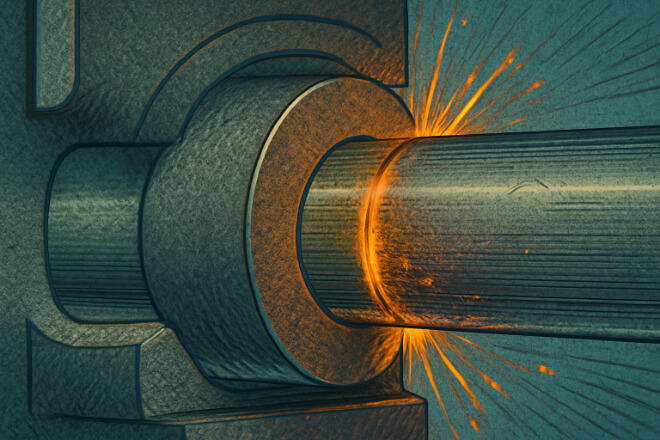

A clearance that is too small causes the most serious damage because it leads to heat and friction.

1). Main Causes

Incorrect machining

열팽창

Installation force distortion

Wrong interference fit

2). Solutions

Re-hone the bushing bore

Increase lubrication flow

Improve shaft cooling

Use a carbide grade with slightly higher thermal expansion

Adjust installation process

3). When to Replace

If the inner wall is scored or heat-damaged, replacement is recommended.

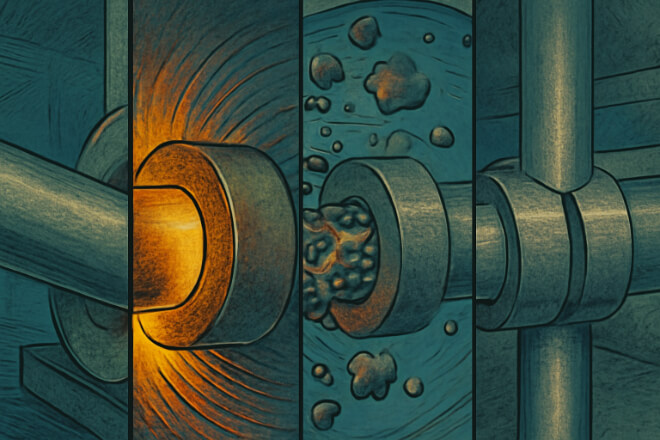

Solving Too-Large Clearance Problems

Large clearance reduces stability and may cause vibration or leakage.

1). Main Causes

Abrasive wear

Long-term operation

Shaft wear

Manufacturing tolerance issues

2). Solutions

Replace worn bushings

Rebuild or hard-coat the shaft

Improve filtration

Use harder carbide grade

Reduce flow turbulence

3). When to Replace

Replace if clearance exceeds the engineering limit or if vibration becomes severe.

Preventing Clearance Problems in the Future

Prevention is always cheaper than repair.

1). Key Prevention Steps

Maintain correct pump alignment

Monitor temperature and vibration

Improve filtration and remove solids

Ensure proper lubrication flow

Use the correct tungsten carbide grade

Avoid sudden start-stop cycles

2). Recommended Maintenance Schedule

| Interval | 행동 | 목적 | Result |

|---|---|---|---|

| 월간 간행물 | Check vibration | Detect instability early | Longer bushing life |

| Quarterly | Check shaft condition | Find wear issues | Lower repair cost |

| Yearly | Inspect bushing clearance | Maintain performance | Better pump reliability |

결론

Bearing clearance problems can cause serious damage to tungsten carbide bushings and the equipment they support.

By understanding the causes, detecting early signs, measuring correctly, and applying the right corrective steps, decision-makers can greatly extend the life of their pumps and reduce downtime.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.