Electric Submersible Pumps (ESP) work in some of the harshest environments in the 석유와 가스 industry. High pressure, abrasive solids, corrosive fluids, and continuous operation make reliability essential.

텅스텐 카바이드 부싱 play a key role in supporting the pump’s rotating shaft and ensuring long service life.

This article explains why tungsten carbide bushings are widely used in ESP systems, what grades work best, and how OEMs can choose the right design for long-term performance.

Why Tungsten Carbide Bushings Are Critical in ESP Systems

ESP systems run at high speeds and experience constant axial and radial loads. This puts extreme stress on bearings and bushings.

Tungsten carbide bushings help maintain shaft alignment, reduce friction, and prevent vibration that could damage the pump.

Key performance requirements in ESP applications

높은 경도 for abrasive conditions

훌륭한 내마모성

Low friction to reduce heat

Good chemical stability in corrosive fluids

Ability to handle continuous operation

Dimensional precision for stable shaft support

In ESP environments, even minor misalignment or wear can lead to pump failure. This is why tungsten carbide is preferred over bronze, steel, or composite materials.

Operating Conditions of ESP That Demand Tungsten Carbide

ESP pumps often operate thousands of meters underground, in wells containing sand, gas, brine, and chemical additives. These conditions require a material that can survive long-term exposure.

Key environmental challenges

High temperature from motor heat and friction

High pressure deep in the well

Sand and solids causing abrasion

Corrosive water or hydrocarbons

High RPM of pump shaft

Continuous running cycles

Tungsten carbide offers the best balance of hardness and 강인함 for this environment.

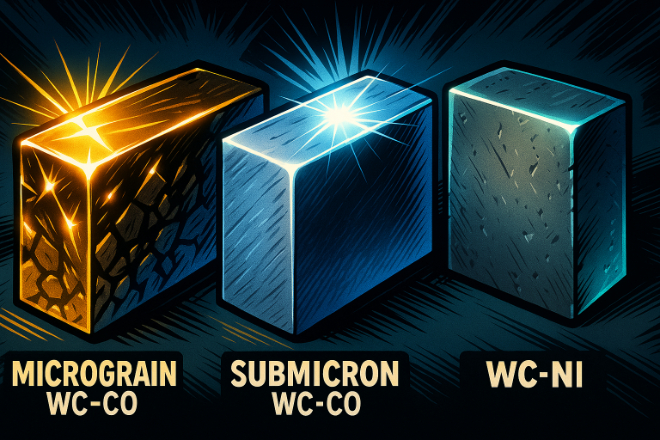

Best Tungsten Carbide Grades for ESP Bushings

Different ESP conditions require different types of tungsten carbide. Two key factors determine grade selection: grain size and binder type.

1). Recommended binder types

Cobalt binder (WC-Co): Strong 강인함, 좋은 내마모성. Best for wells with solids and high abrasion.

Nickel binder (WC-Ni): Higher 내식성. Best for wells with brine, seawater, or aggressive chemicals.

2). Common ESP Grades Comparison

| 학년 유형 | 접합재 | Strengths | 최적의 지원서 |

|---|---|---|---|

| Micrograin WC-Co | Cobalt | High hardness, excellent wear life | Abrasive wells with sand |

| Submicron WC-Co | Cobalt | Low friction, high precision | High-speed ESP shafts |

| WC-Ni Grade | Nickel | 탁월한 내식성 | Brine, seawater, corrosive wells |

Design Factors for ESP Tungsten Carbide Bushings

Correct design is just as important as material grade. ESP bushings must be made with high precision to avoid shaft damage or pump vibration.

1). Key design considerations

Tight dimensional tolerance: Helps ensure stable shaft rotation.

Smooth surface finish: ESP typically requires Ra ≤ 0.2 µm.

Correct clearance fit: Too tight = heat buildup; Too loose = vibration and premature wear

Oil or fluid grooves: Helps lubrication and cooling.

Concentricity and roundness: Must be controlled to minimize vibration.

Proper design improves overall ESP system efficiency.

Installation and Alignment Considerations

Even the best material will fail early if installation is incorrect.

1). Installation priorities

Shaft and bushing must be aligned precisely

No excessive force during press-fit

Avoid thermal shock during installation

Clean all sand or debris before assembly

Use correct lubrication during assembly

2). Common alignment issues

Shaft misalignment

Bent shaft

Wrong clearance

Poor surface matching

3). Alignment Problem Table

| 문제 | Cause | Impact on ESP |

|---|---|---|

| Misalignment | Poor installation | Vibration, faster wear |

| Wrong clearance | Incorrect measurement | Heat, shaft scoring |

| Bent shaft | Mechanical load | Poor rotation stability |

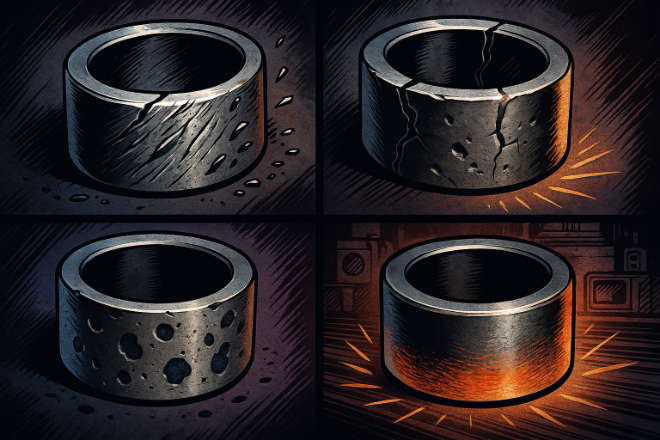

Failure Modes of Tungsten Carbide Bushings in ESP

Understanding how bushings fail helps improve design and material choice.

1). Common failure modes

Abrasive wear (sand cutting the surface)

Corrosion from brine or chemicals

Thermal cracking from overheated shaft

Chipping from impact or misalignment

Binder leaching in aggressive fluids

Monitoring failure patterns helps OEMs optimize their pump design and maintenance schedule.

Selecting the Right Supplier for ESP Bushings

ESP applications require high reliability, so choosing a trustworthy supplier is essential.

1). Supplier checklist

Ability to provide cobalt and nickel binder grades

Strict powder control and traceability

Sintering and HIP equipment

Experience in oil and gas applications

Fast lead times for replacement parts

A strong supplier reduces risk and ensures long-term ESP performance.

결론

Tungsten carbide bushings are essential for the reliability of Electric Submersible Pumps. Their hardness, wear resistance, and stability make them ideal for harsh oilfield conditions.

By selecting the right grade, design, installation practices, and supplier, OEMs can greatly extend ESP service life and reduce downtime.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.