에서 채광 industry, the efficiency of equipment plays a critical role in maintaining productivity and reducing operational costs.

Mining tools and machinery are often subjected to harsh environments that cause significant wear and tear.

Tungsten carbide tips are widely used in mining equipment for their exceptional 경도, 내마모성, and durability, making them ideal for demanding applications.

This blog will explore how tungsten carbide tips enhance the efficiency of mining equipment by improving performance, extending tool life, and reducing downtime.

Why Tungsten Carbide Tips Are Essential for Mining Equipment

Mining operations often involve high-impact, abrasive, and high-temperature conditions that require durable tools.

Tungsten carbide tips are commonly used in mining equipment due to their unique properties that help increase the overall efficiency of the equipment.

1). 우수한 경도

Tungsten carbide is one of the hardest materials known, making it an ideal choice for tools exposed to abrasive materials like rock and ore.

Its hardness allows carbide tips to maintain their cutting edges longer than traditional materials, leading to improved performance in mining equipment.

2). 내마모성

Mining tools are subjected to constant friction, which can cause rapid wear and tear.

Tungsten carbide tips resist wear far better than other materials, reducing the frequency of tool replacements and minimizing downtime.

This wear resistance is critical in maintaining the efficiency of mining equipment over time.

3). Impact Resistance

Mining equipment often faces shocks and impacts when drilling or excavating in hard rock.

Tungsten carbide’s 강인함 makes it resistant to these forces, ensuring that tools remain intact and effective, even under extreme conditions.

This impact resistance directly enhances equipment reliability and performance.

How Tungsten Carbide Tips Improve Mining Equipment Efficiency

Tungsten carbide tips contribute to improved mining equipment efficiency in several ways. From reducing downtime to extending tool life, these tips provide significant benefits that enhance overall productivity.

1). Extended Tool Life

Due to their 내마모성 그리고 경도, tungsten carbide tips last much longer than tools made from other materials.

The extended lifespan of carbide tips reduces the need for frequent tool changes, which results in less downtime and lower maintenance costs for mining equipment.

Tools that last longer contribute to the continuous operation of mining equipment, increasing overall productivity.

2). Increased Cutting and Drilling Efficiency

Tungsten carbide tips can maintain sharpness and performance even in tough conditions.

As a result, mining tools that incorporate carbide tips can cut and drill through hard materials with greater efficiency.

This efficiency reduces the amount of time required to complete mining tasks and accelerates the production process, allowing mining operations to be more productive.

3). Reduced Maintenance and Operational Costs

Because tungsten carbide tips extend tool life, reduce wear, and maintain cutting precision, mining companies can significantly lower their maintenance and operational costs.

Fewer tool replacements, less downtime, and lower maintenance efforts translate into cost savings and improved profitability for mining operations.

Performance Factors Influencing Tungsten Carbide Tips in Mining

While tungsten carbide tips offer exceptional performance, several factors influence how effectively they enhance mining equipment efficiency.

Understanding these factors is crucial for maximizing the benefits of carbide tips in mining operations.

1). Cutting Speed and Feed Rate

Optimizing cutting speed and feed rate is important to ensure that carbide tips operate efficiently.

Operating at the right speed prevents excessive heat buildup, which can affect tool performance.

Tungsten carbide tips perform well at higher cutting speeds, but it is essential to adjust cutting parameters based on material hardness and tool wear to avoid premature tool failure.

2). Material Being Cut

그만큼 경도 and abrasiveness of the material being cut directly affect the performance of tungsten carbide tips.

Softer materials may not wear down carbide tips as quickly, but hard and abrasive materials, such as granite or ore, put more stress on the tools.

Mining operations often face varying material conditions, so it is essential to choose the appropriate carbide grade for each specific material.

3). Tool Geometry

The geometry of the carbide tip plays a significant role in how it performs during mining operations.

The rake angle, relief angle, and cutting edge design all impact how well the tool cuts and handles stress.

Performance testing and optimization of tool geometry are important to achieve the best results in terms of efficiency and durability.

Applications of Tungsten Carbide Tips in Mining Equipment

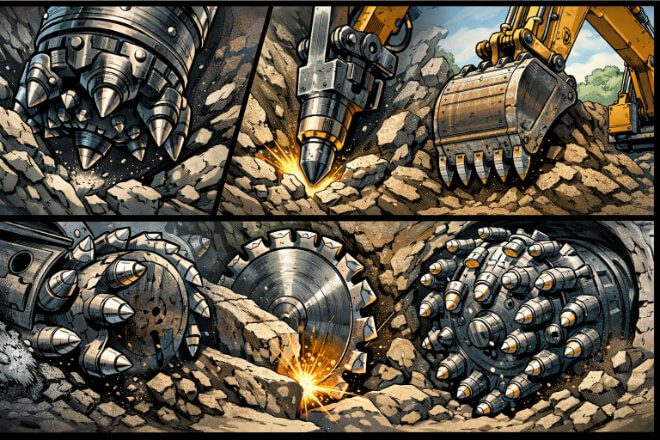

Tungsten carbide tips are used in a variety of mining equipment, each designed for specific tasks that require high-performance tools. Some of the key applications include:

1). Drilling Tools

In mining, drilling tools are used to create holes for blasting or material extraction.

Tungsten carbide tips are used in drill bits to ensure that they can withstand the intense pressures and abrasiveness of rock and soil.

The hardness and impact resistance of carbide tips make them ideal for drilling operations.

2). Excavation Tools

Excavation tools, such as bucket teeth and ripper points, often encounter tough, rocky materials. Tungsten carbide tips are commonly used in these tools to enhance their durability and reduce wear.

그만큼 내마모성 of carbide tips helps ensure that these tools continue to perform effectively during the excavation process.

3). Cutting Tools for Hard Materials

In mining, cutting tools used for materials like coal, ore, and minerals require precision and durability.

Tungsten carbide tips offer the cutting power needed to handle these materials while maintaining tool integrity.

The long-lasting sharpness of carbide tips improves the quality of the cut and reduces the time required to extract materials.

Maximizing Mining Efficiency with Tungsten Carbide Tips

To get the most out of tungsten carbide tips, mining operations must ensure they are using the tools correctly and maintaining them properly.

Here are some key strategies for maximizing the efficiency of mining equipment with carbide tips:

1). Regular Maintenance and Inspections

Regularly inspecting carbide tips for wear and damage helps ensure they are functioning at their best.

If any wear or cracks are detected, the tools should be replaced or reconditioned to maintain optimal performance.

Routine maintenance reduces the likelihood of equipment breakdowns and extends the life of carbide tips.

2). Optimizing Operating Conditions

Adjusting cutting speeds, feed rates, and depths of cut based on the material being worked on helps maximize the performance of carbide tips.

Properly optimizing these parameters helps minimize tool wear and improve the overall efficiency of mining operations.

3). Choosing the Right Carbide Grade

Not all tungsten carbide grades are the same, and different grades are suitable for different types of mining operations.

It is essential to select the appropriate grade of carbide based on the 경도 and abrasiveness of the materials being cut or drilled.

Using the right grade ensures that the tips maintain performance for longer periods.

결론

Tungsten carbide tips are indispensable in improving the efficiency of mining equipment.

Their hardness, wear resistance, and impact resistance make them ideal for cutting, drilling, and excavation tasks in tough mining environments.

By using tungsten carbide tips, mining companies can extend tool life, reduce downtime, and improve overall productivity.

Investing in carbide tips is a smart choice for businesses seeking to optimize their mining operations and achieve greater efficiency in the long run.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.