Tungsten carbide tips are known for their durability and 내마모성, making them a popular choice for high-performance applications in industries like 채광, machining, and construction.

However, one issue that can arise in high-speed operations is vibration. Excessive vibration can lead to reduced performance, increased wear, and even premature failure of the tungsten carbide tips.

In this article, we’ll explore how to identify vibration problems with tungsten carbide tips, the potential causes of these issues, and strategies for addressing them to improve performance and extend the lifespan of your equipment.

Why Vibration is a Problem for Tungsten Carbide Tips

Vibration can have a significant impact on the performance of tungsten carbide tips, especially in applications where precision and durability are crucial. Excessive vibration can cause the following problems:

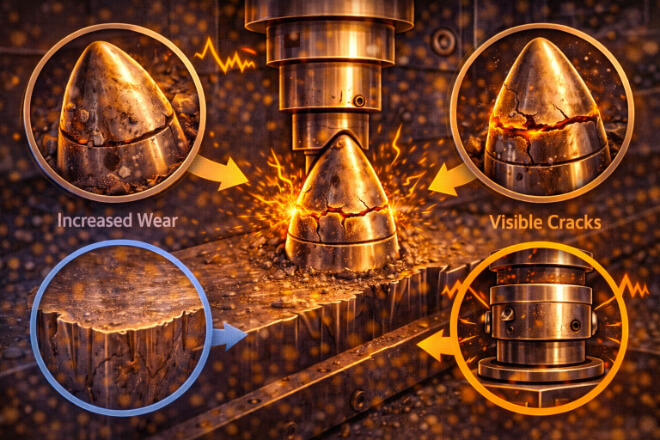

Increased Wear: Vibration leads to constant friction and impact, which accelerates the wear of tungsten carbide tips.

Reduced Cutting Efficiency: Vibration can cause the tips to lose their effectiveness in cutting or grinding, resulting in lower productivity.

Tip Chipping or Cracking: High levels of vibration can cause stress fractures, leading to chips or cracks in the tips, which compromise their performance.

Equipment Damage: Vibrations can be transmitted through the equipment, leading to damage in other components, which can affect the overall system efficiency.

Identifying and addressing vibration problems early can prevent these issues, ensuring that tungsten carbide tips continue to perform optimally.

Identifying Vibration Problems in Tungsten Carbide Tips

1). Excessive Tool Wear

One of the first signs of vibration problems is increased tool wear.

If you notice that your tungsten carbide tips are wearing down faster than expected, it may be due to excessive vibration.

Vibration can cause the tip to repeatedly come into contact with the workpiece in an uneven manner, leading to accelerated wear on the surface.

Signs: Unusually fast wear or uneven wear patterns on the carbide tips.

해결책: Inspect the tool for signs of vibration-related damage. Ensure the machine is calibrated and that the workpiece is held securely.

2). Inconsistent Surface Finish

If you are using tungsten carbide tips for cutting, grinding, or milling, vibration can result in an inconsistent surface finish.

Vibrations can cause the tips to skip or bounce off the material, leading to an uneven surface.

This is especially critical in applications that require precise, smooth finishes.

Signs: Rough or inconsistent surface finishes, visible tool marks.

해결책: Measure the surface finish regularly. If vibration is suspected, check for loose components or misalignment in the machine.

3). Unusual Noises or Shaking

Vibration is often accompanied by unusual noises or shaking during operation.

If you hear a rattling or buzzing sound coming from the machine or notice the equipment shaking more than usual, it may indicate excessive vibration affecting the tungsten carbide tips.

Signs: Loud or unusual sounds, visible shaking or movement in the machine.

해결책: Reduce machine speed or stop the operation to inspect the equipment. Look for loose components, misalignment, or worn-out bearings.

4). Cracks or Chips in the Tungsten Carbide Tips

Vibration can cause tungsten carbide tips to crack or chip, especially if the vibration is sustained over a long period.

These cracks or chips can reduce the effectiveness of the tips and lead to premature failure.

Signs: Visible cracks or chips on the edges or surface of the carbide tips.

해결책: Inspect tips regularly for damage. Replace tips that show signs of cracking or chipping.

Causes of Vibration Problems in Tungsten Carbide Tips

Vibration problems with tungsten carbide tips can arise from several factors.

Understanding the root cause is essential for addressing the issue effectively. Here are some common causes of vibration:

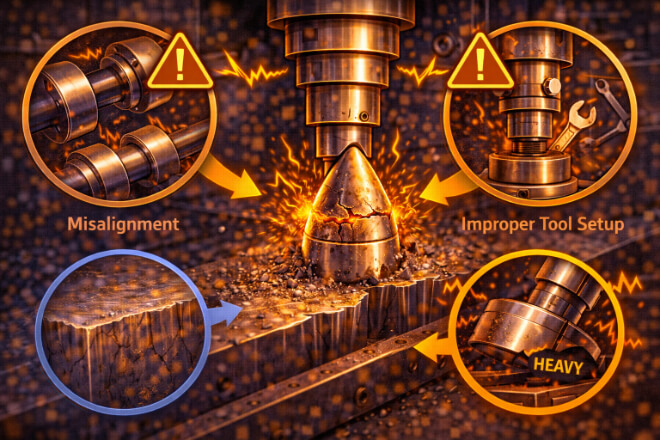

1). Machine Misalignment

One of the most common causes of vibration is misalignment in the machine.

If the machine components, such as the spindle or tool holder, are not properly aligned, it can create uneven force distribution during operation, leading to vibration.

This is especially problematic in high-speed applications.

해결책: Regularly calibrate and align the machine to ensure that the components are in proper working order.

2). Improper Tool Setup

Incorrect setup of the tungsten carbide tip, including improper mounting or tool positioning, can cause vibration.

If the tool is not properly secured or positioned at the correct angle, it can lead to excessive force on the tip during operation, causing vibration.

해결책: Ensure that the tungsten carbide tip is properly installed and securely mounted. Double-check the tool setup before starting the operation.

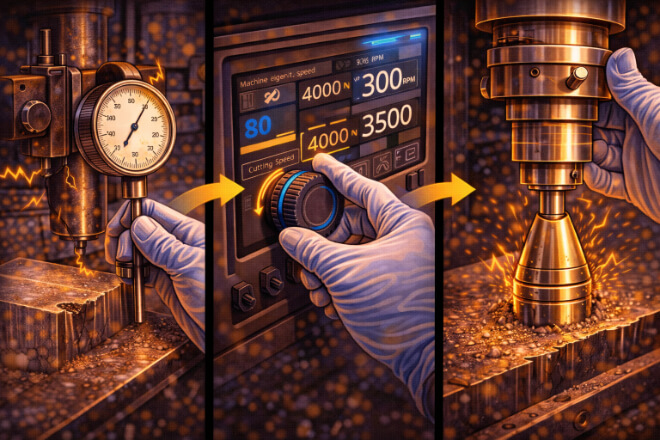

3). Excessive Machine Speed

Running the machine at excessive speeds can increase the likelihood of vibration.

High speeds can amplify any existing misalignments or imbalances, leading to higher levels of vibration that affect the tungsten carbide tips.

해결책: Reduce the speed of the machine if vibration becomes noticeable. Operate within the recommended speed range for the equipment and material being processed.

4). Imbalance in the Workpiece

If the workpiece is not properly balanced, it can lead to uneven forces on the tungsten carbide tip, resulting in vibration.

An unbalanced workpiece can cause the tip to make inconsistent contact with the material, leading to uneven wear and poor performance.

해결책: Ensure the workpiece is properly mounted and secured in place. Use balancing equipment to ensure the workpiece is stable during operation.

5). Worn Machine Components

Worn-out machine components, such as bearings or gears, can cause instability and vibration during operation.

If the components that support the spindle or tool holder are worn, it can result in excessive movement, which affects the performance of the tungsten carbide tips.

해결책: Regularly inspect machine components for wear and replace any damaged or worn parts.

Addressing Vibration Problems with Tungsten Carbide Tips

1). Proper Machine Calibration and Alignment

To prevent vibration, regularly calibrate and align your machinery.

Ensure that the tool holder, spindle, and workpiece are properly aligned to prevent uneven force distribution that can lead to vibration.

행동: Schedule regular maintenance and calibration of your equipment to maintain optimal alignment.

2). Adjusting Cutting Speed and Feed Rates

Reducing the cutting speed and adjusting feed rates can help mitigate vibration problems.

Slower speeds allow the tungsten carbide tips to engage the material more smoothly, reducing the impact of vibration.

행동: Monitor cutting speeds and adjust them to minimize vibration without compromising the quality of the work.

3). Upgrading to Vibration-Damping Tool Holders

Consider upgrading your tool holders to those designed with vibration-damping features.

These tool holders absorb vibrations, preventing them from reaching the tungsten carbide tips and causing damage.

행동: Invest in high-quality, vibration-damping tool holders to reduce the risk of vibration-related issues.

4). Regular Inspection and Maintenance

Regular inspection and maintenance of both the tungsten carbide tips and the machinery are crucial for preventing vibration-related problems.

Check for wear, cracks, or chips in the tips, and ensure that the machine components are in good condition.

행동: Perform routine maintenance checks and replace any worn or damaged parts promptly.

결론

Vibration problems can significantly affect the performance and durability of tungsten carbide tips, leading to increased wear, poor surface finish, and premature failure.

By identifying the signs of vibration, understanding the causes, and taking the necessary steps to address the issue, you can ensure that your tungsten carbide tips continue to perform at their best.

Proper machine calibration, tool setup, and regular maintenance are key to preventing vibration and maximizing the longevity of your equipment.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.