When you’re working with CNC machines or any high-precision application, the tools you choose can make or break your results.

텅스텐 카바이드 절삭 공구 are popular because they’re strong, long-lasting, and great for high-speed machining. But not all carbide tools are created equal.

In this guide, we’ll walk you through how to tell if a tungsten carbide cutting tool is truly high quality.

Whether you’re buying tools for the first time or trying to avoid poor-performing imports, this post will help you make smarter choices.

1. What Makes Tungsten Carbide So Special?

Tungsten carbide is a super-hard material made from a mix of tungsten and carbon atoms.

It’s tougher than steel and can handle high heat, which is why it’s used in cutting tools for metal, wood, plastics, and more.

But just because something is made of carbide doesn’t mean it’s good. There are different grades, grain sizes, binders, and even fake blends out there.

To make sure you’re getting a tool that performs well and lasts, you need to know what to look for.

2. Key Signs of a High-Quality Carbide Cutting Tool

Let’s break down the major things you should check when choosing a good tungsten carbide cutting tool.

1). Material Grade and Grain Structure

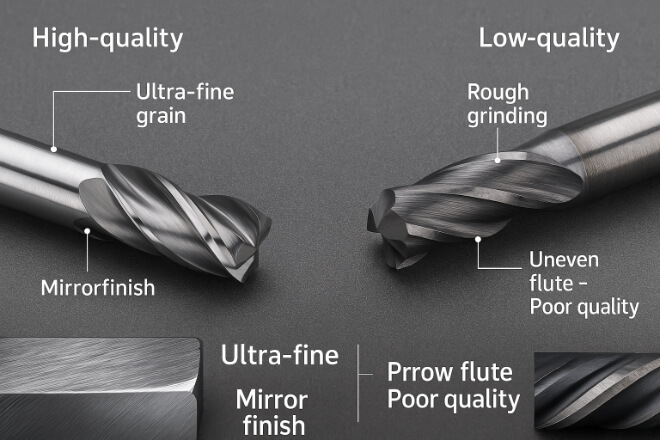

One of the most important things is the grade of carbide. Quality tools use fine or ultra-fine grain carbide, which gives you better 경도 그리고 내마모성.

Cheaper tools often use recycled or coarse-grain material, which dulls faster and may chip more easily.

Look for: micro-grain or ultra-fine carbide grade

Avoid: tools that don’t list their grade or use mixed scrap powders

2). Sharpness and Edge Geometry

A good cutting tool should have a precisely ground cutting edge. This isn’t just about being sharp — it’s about the geometry.

The angles and smoothness of the edge affect cutting speed, surface finish, and tool life.

Check the tool under a magnifier: the edge should look clean, consistent, and free from chips.

Look for symmetrical flute shapes and polished cutting edges.

If you see rough grinding, uneven tips, or chips before even using it — that’s a red flag.

3). Coating Quality

Many carbide tools are coated to improve performance. Coatings reduce friction, increase heat resistance, and make tools last longer. Common coatings include:

| 코팅 유형 | 이익 | 최상의 사용 |

|---|---|---|

| 주석 | Low friction, wear resistance | 일반 가공 |

| TiAlN / AlTiN | Great heat resistance | Dry machining, steels |

| 다운로드 가능 콘텐츠 | Prevents aluminum sticking | Soft materials like aluminum |

| CVD 다이아몬드 | Super hard, abrasion-resistant | Composites, graphite |

A quality tool will have a smooth, even coating with no bubbles, flaking, or bare spots. Poor coatings wear off quickly and won’t help your tool much.

4). Hardness and Toughness Balance

Tungsten carbide is known for its hardness — but hardness alone isn’t enough. The best tools balance hardness and toughness.

If a tool is too brittle, it will chip or break under stress. If it’s too soft, it dulls too quickly.

HRA rating (Rockwell A hardness) above 90 is generally a good sign

TRS (Transverse Rupture Strength) shows toughness. Look for higher TRS ratings for roughing tools.

You won’t always see this on the packaging, but reputable manufacturers often share it in their spec sheets.

5). Precision Tolerances

High-quality carbide tools are made to tight tolerances. This means the size, shape, and balance of the tool are carefully controlled during manufacturing.

Loose tolerances lead to poor fits, vibration, and lower machining accuracy.

If you’re using carbide tools for CNC machining, tolerances matter more than you think. Poorly made tools can cause:

Tool runout

Vibration (leading to tool wear and poor finish)

Reduced cutting accuracy

6). Brand Reputation and Certification

In today’s market, there are hundreds of no-name tool sellers offering “cheap” carbide tools.

But you often get what you pay for. Reputable brands test their tools, back them with technical support, and provide real specs.

Check if the manufacturer has ISO certifications

Look for clear product data and application guidelines

Read reviews and case studies if available

Well-established brands also offer consistent quality, so you can rely on getting the same results every time you order.

7). Weight and Feel

This may sound basic, but experienced machinists often judge tool quality by its feel. A well-made tungsten carbide tool will feel solid and dense.

Lightweight or hollow-feeling tools may be using lower-grade binders or diluted carbide mixtures.

When handling the tool:

Feel for weight and density

Check for balanced construction

Tap the shank lightly — a clean, metallic ring often means a dense, quality core

8). Surface Finish and Polish

Quality carbide tools often have a polished surface, especially on the cutting edge and flutes.

This reduces chip sticking and friction. Rough surfaces on cheaper tools can cause chips to jam, increase cutting heat, and wear faster.

You’ll often find:

Mirror polish on tools made for aluminum or plastic

Smooth flute walls to guide chips out quickly

Uniform finish all around — no tool should look “half-finished”

3. Quick Checklist: How to Spot a Quality Carbide Tool

Here’s a simple checklist to help you identify quality when shopping for tungsten carbide cutting tools:

Ultra-fine grain carbide

Clean and sharp cutting edge

Consistent, high-quality coating

균형 잡힌 경도와 인성

Precision-ground with tight tolerances

Made by a certified, reputable brand

Feels dense and solid in hand

mooth surface finish and polished flutes

4. Common Warning Signs of Low-Quality Carbide Tools

To help you avoid wasting money, here are red flags that usually indicate a poor-quality tool:

No information on material grade or coating

Visible chips or rough edges straight out of the box

Uneven flute shapes or asymmetrical design

Flaking, faded, or missing coating

The tool feels light, hollow, or imbalanced

Vague product descriptions or no certification

Low-quality tools may work for a few jobs, but they often fail early, ruin workpieces, and cause unexpected downtime.

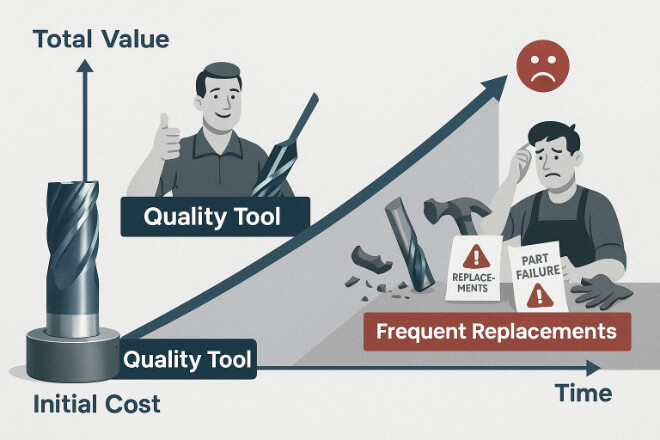

5. Why It Matters to Invest in Good Tools

High-quality tungsten carbide cutting tools may cost more upfront, but they save you money in the long run. You’ll get:

더 긴 공구 수명

Better part accuracy

Cleaner surface finishes

Less downtime and fewer tool changes

Higher overall productivity

Whether you’re a machine shop owner or a manufacturer looking to scale, investing in good tools is always a smart move.

마지막 생각

Finding quality tungsten carbide cutting tools isn’t hard once you know what to look for. From the material grade to the coating and finish, every detail matters.

Stick with tools that are made from top-grade carbide, backed by real specs, and trusted by professionals. You’ll see the difference in tool life, part quality, and even your bottom line.

Need help choosing the right tool for your job? Visit 레톱즈 — they carry a wide range of high-quality carbide cutting tools and can help you pick the best one for your application.