오늘날 사람들은 그 어느 때보다 지속가능성에 관심을 갖고 있습니다. 개인의 선택부터 산업 운영에 이르기까지 모든 사람이 폐기물을 줄이고, 에너지를 절약하고, 지구를 위해 더 나은 결정을 내리기 위해 노력하고 있습니다.

하지만 기계 가공과 제조에 대해 이야기할 때 환경적 영향은 종종 간과됩니다. 바로 그 부분이죠. 텅스텐 카바이드 절단 도구 그림 속에 등장합니다.

이러한 도구들은 매우 단단하고 오래가는 것으로 알려져 있지만, 이것이 환경에 미치는 영향은 무엇일까요? 폐기물 감소에 도움이 될까요, 아니면 그저 환경을 심각하게 오염시키는 또 다른 산업 제품일까요?

텅스텐 카바이드 절삭 공구를 사용할 때의 실제 환경 영향과 이것이 여러분의 작업장에서 더 친환경적인 선택 중 하나가 될 수 있는 이유를 알아보겠습니다.

1. 지속 가능성에 있어 도구 소재가 중요한 이유

사용하는 모든 도구에는 환경적 비용이 따릅니다. 여기에는 도구 제작에 사용된 재료, 생산 및 운송에 필요한 에너지, 그리고 교체 빈도가 포함됩니다.

고속강이나 기타 합금으로 만든 값싼 도구는 종종 빨리 마모됩니다.

즉, 더 자주 교체해야 하며, 채굴, 제조가 늘어나고 낭비도 늘어납니다.

텅스텐 카바이드 공구는 다릅니다. 수명이 더 길고, 재연마나 재코팅이 가능하기 때문에 시간이 지남에 따라 필요한 공구의 개수가 줄어듭니다. 이는 지속가능성에 큰 도움이 됩니다.

2. 더 긴 도구 수명 = 더 적은 낭비

텅스텐 카바이드 절삭 공구의 가장 큰 환경적 이점 중 하나는 긴 수명입니다. 이 공구는 다른 소재보다 최대 10배 더 오래 사용할 수 있습니다.

그게 왜 중요할까요? 낡은 도구를 버릴 때마다, 그것을 만드는 데 들어간 모든 자원과 에너지가 함께 사라지는 거잖아요.

도구의 수명이 길어지면 매립지에 버려지는 도구가 줄어들고 원자재를 채굴할 필요성도 줄어듭니다.

이는 공구 교체가 잦은 대량 가공 작업에서 특히 중요합니다. 초경 공구로 전환함으로써 제조업체는 폐기물을 줄이고 환경에 미치는 영향을 줄일 수 있습니다.

3. 더 나은 성능은 에너지 사용을 줄입니다

텅스텐 카바이드 공구는 수명이 더 길 뿐만 아니라 성능도 더 좋습니다.

날카로움이 오랫동안 유지되고 더 빠른 속도도 견딜 수 있기 때문에 기계가 더 효율적으로 작동합니다.

즉, 더 적은 횟수로 더 빠르게 절단할 수 있으며, 부품당 에너지 소비도 줄일 수 있습니다.

에너지 사용량이 적을수록 탄소발자국도 줄어듭니다.

예를 들어, CNC 기계가 더욱 공격적인 이송과 속도를 처리할 수 있기 때문에 사이클당 소요되는 시간이 줄어들면 전기 요금이 낮아지고 환경 점수가 올라갑니다.

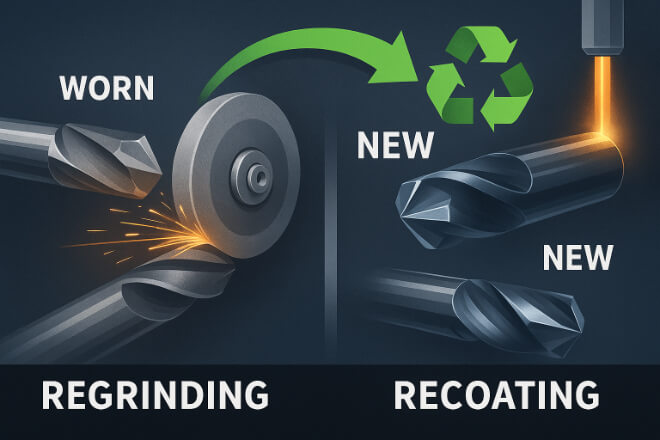

4. 재연마 및 재코팅 옵션

초경 공구의 큰 장점은 버려지는 대신 재연마하거나 재코팅할 수 있다는 것입니다. 덕분에 두 번째(혹은 세 번째) 수명을 누릴 수 있습니다.

재연마는 마모된 공구를 새것처럼 날카롭게 연마하는 과정입니다. 재코팅은 성능을 향상시키고 마모를 줄이기 위해 새로운 보호 코팅층을 추가합니다.

도구가 둔해질 때마다 새 도구를 사는 대신, 오래된 도구를 재활용하면 환경 비용을 크게 줄일 수 있습니다.

5. 텅스텐 카바이드의 재활용성

텅스텐 카바이드는 100% 재활용이 가능합니다. 실제로 많은 공구 제조업체에서 재활용 카바이드를 제품에 사용하고 있습니다.

도구의 수명이 다하면, 도구를 갈아서 가루로 만들어 새로운 도구를 만들 수 있습니다.

텅스텐 카바이드는 다른 소재에 비해 재활용성이 뛰어납니다.

카바이드를 회수하고 재사용하려는 전 세계적 노력은 신규 텅스텐 채굴의 필요성을 줄이는 데 도움이 됩니다. 이 과정은 책임감 있게 수행되지 않으면 환경에 해로울 수 있습니다.

재활용을 위해 사용된 초경 공구를 수용하는 공급업체와 협력하면 순환 고리를 형성하고 낭비를 줄일 수 있습니다.

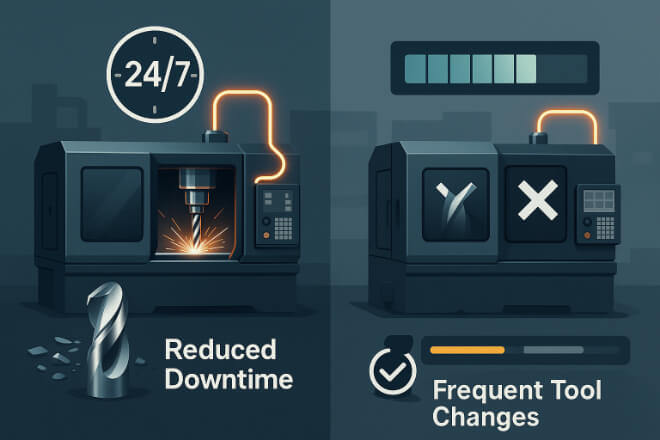

6. 도구 교체 횟수 감소 = 가동 중지 시간 영향 감소

공구가 마모되어 교체해야 할 때마다 기계는 멈춥니다. 이러한 가동 중단 시간은 생산성 손실뿐만 아니라 기계가 유휴 상태이거나 재가동되면서 에너지 낭비로 이어집니다.

초경 공구는 이러한 문제를 줄이는 데 도움이 됩니다. 초경 공구는 마모가 느리고 성능이 더 오래 유지되기 때문에 교체 횟수가 줄어듭니다. 즉, 작업 흐름이 더 원활해지고 환경에 미치는 영향도 줄어듭니다.

또한 인적 오류도 줄어듭니다. 도구 교체 횟수가 줄어들면 설정 실수가 줄어들어 부품 불량으로 이어질 수 있습니다. 결국 누구도 원하지 않는 낭비가 늘어나는 셈입니다.

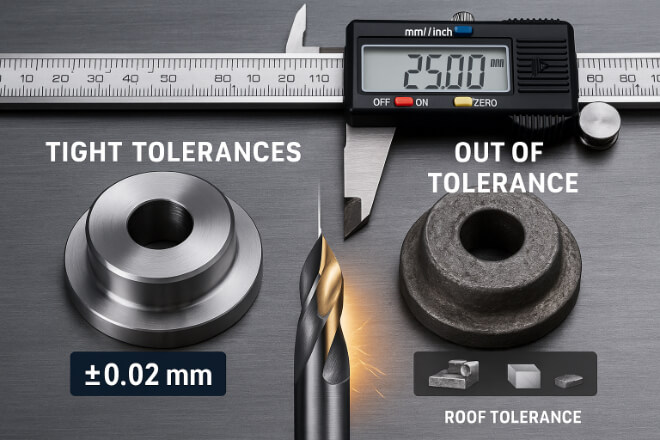

8. 스크랩 감소, 더 나은 허용 오차

무뎌지거나 품질이 낮은 도구는 고철로 이어집니다. 허용 오차를 벗어난 부품, 불량한 표면 마감, 또는 파손된 부품은 모두 폐기물로 버려집니다. 이는 재료, 시간, 그리고 에너지의 낭비입니다.

텅스텐 카바이드 공구는 정밀한 공차를 더 잘 유지합니다. 날카로움과 견고함은 진동과 떨림을 줄여 더욱 깔끔한 절단과 더욱 정확한 부품 가공을 가능하게 합니다.

즉, 다시 해야 할 일이 줄어들고, 첫 번째 수율이 높아지며, 재료 낭비도 줄어듭니다.

9. 책임 있는 소싱 및 인증

텅스텐 채굴은 환경적 문제를 야기할 수 있지만, 많은 현대 공급업체는 이제 더 엄격한 조달 및 환경 기준을 따릅니다.

도구를 선택할 때 재활용 카바이드를 사용하거나 책임감 있는 광산 작업과 협력하는 회사를 찾으세요.

ISO 14001과 같은 인증은 제조업체가 환경에 미치는 영향을 최소화하기 위해 노력하고 있음을 보여줍니다.

10. 탄소 발자국 비교

간단한 예를 들어 설명해보겠습니다.

| 공구 재료 | 평균 공구 수명 | 생산된 폐기물 | 부분당 에너지 | 재활용 가능? |

|---|---|---|---|---|

| 고속도강 | 낮은 | 높은 | 더 높은 | 부분적으로 |

| 카바이드(재연마 없음) | 중간 | 중간 | 중간 | 예 |

| 카바이드(재활용 + 재분쇄) | 높은 | 낮은 | 낮은 | 예 |

보시다시피, 가장 좋은 시나리오는 고품질 텅스텐 카바이드 공구를 다시 갈아서 재코팅한 후 결국 재활용하는 것입니다.

마지막 생각

친환경적이라고 해서 항상 부드러운 재질을 선택하는 것은 아닙니다. 텅스텐 카바이드 절삭 공구의 경우, 더 강한 재질을 선택하는 것이 실제로 더 지속 가능한 선택일 수 있습니다.

더 오래 지속되고 재활용 가능하며 고성능 도구에 투자하면 폐기물을 줄이고, 에너지 사용량을 줄이며, 기계 가공 작업을 더 친환경적으로 수행할 수 있습니다.

그리고 신뢰할 수 있는 공급업체로부터 구매할 때 레톱즈전문가의 지원, 책임감 있는 조달, 오래 지속되도록 설계된 도구 등의 추가적인 혜택을 누릴 수 있습니다.

더욱 스마트하고 친환경적인 가공을 원하시나요? 도구부터 시작해 보세요.