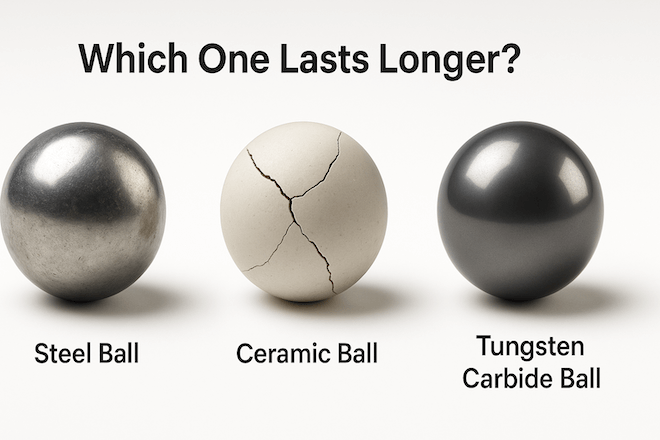

When it comes to precision balls used in machines, tools, or measuring equipment, tungsten carbide balls are often the best choice. But why choose them instead of steel balls or ceramic balls?

This article will give you a simple, clear comparison so you can understand the key advantages of tungsten carbide balls, especially if you are new to engineering or manufacturing.

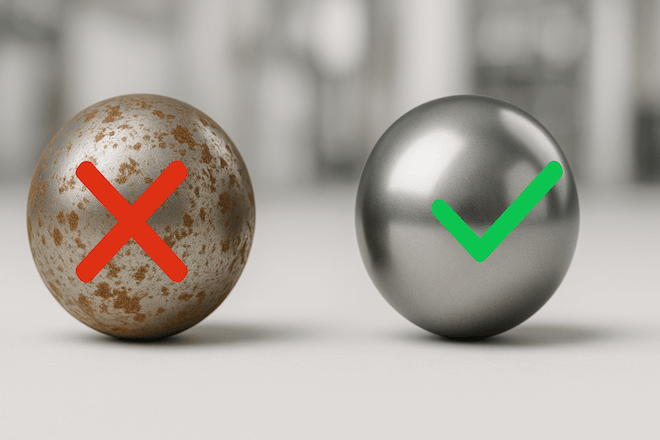

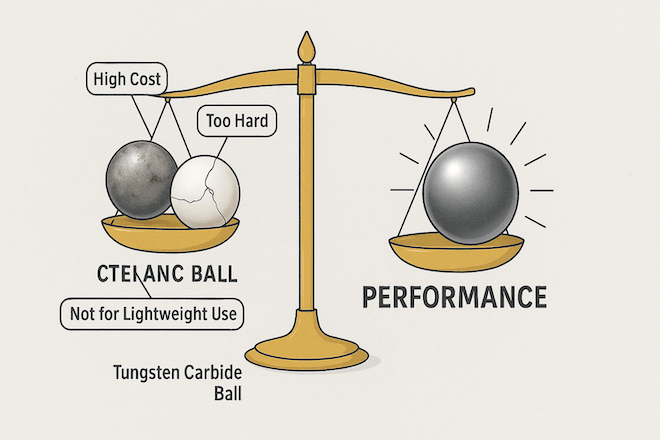

Common Problems with Steel Balls

Steel balls are widely used, but they have some problems:

Wear and Tear: Steel balls lose shape after long use.

Rusting: Even stainless steel can corrode in harsh environments.

Lower Hardness: They can’t handle high-speed or heavy-load applications.

While steel balls are cheaper, they usually need to be replaced more often.

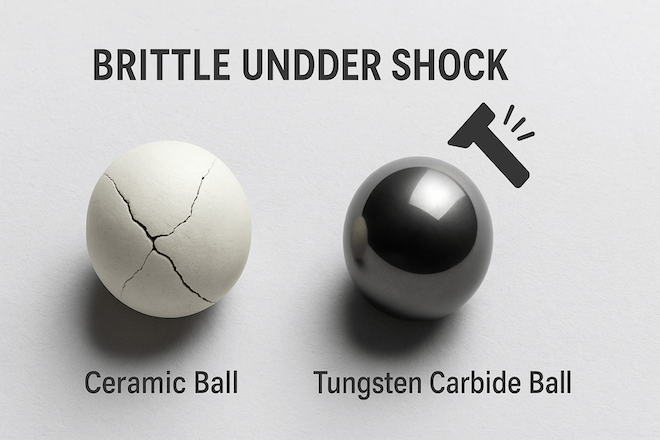

Common Problems with Ceramic Balls

Ceramic balls are lightweight and resist corrosion well. But they have their own issues:

Brittle: They can crack under sudden force or shock.

Hard to Polish: It’s harder to make them as smooth as tungsten carbide.

Low Impact Resistance: Not suitable for high-load or fast-moving parts.

Ceramic balls work well in some environments, but they are not always reliable for heavy-duty use.

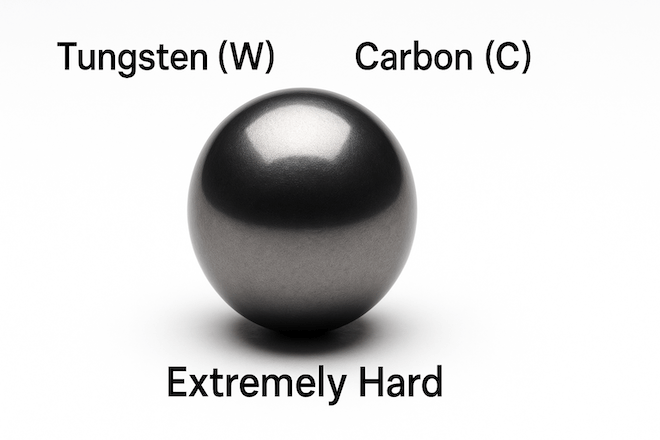

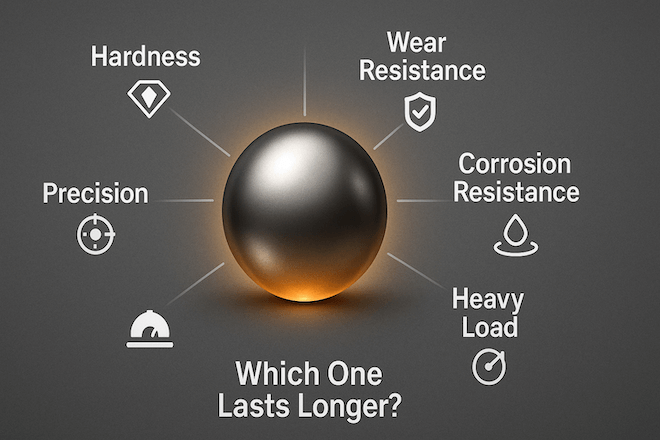

Tungsten Carbide Balls: Key Advantages

Let’s compare tungsten carbide to steel and ceramic in simple terms:

| 특징 | 텅스텐 카바이드 볼 | Steel Balls | Ceramic Balls |

|---|---|---|---|

| 경도 | ★★★★★ (Very High) | ★★★☆☆ (Medium) | ★★★★☆ (High) |

| 내마모성 | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| 부식 저항성 | ★★★★☆ | ★★☆☆☆ | ★★★★★ |

| Shock Resistance | ★★★★☆ | ★★★★☆ | ★★☆☆☆ |

| Lifespan | Very Long | 중간 | Medium to Long |

| 비용 | 더 높은 | 낮은 | 중간 |

As you can see, tungsten carbide balls are a balanced and powerful option for many industries.

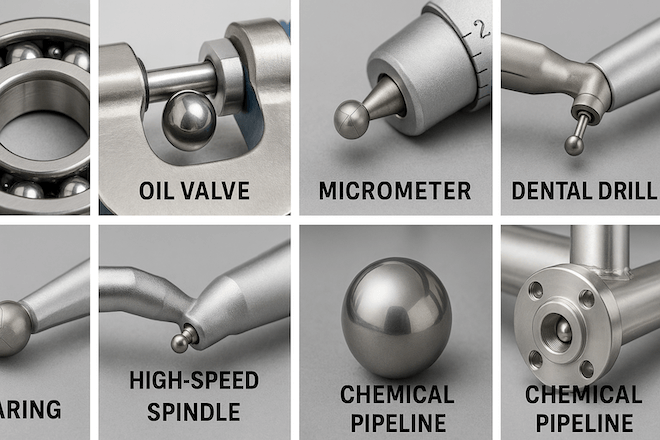

Where Tungsten Carbide Balls Win

Here are some real cases where tungsten carbide balls are a better option:

High-Speed Bearings

They hold shape and size even at high RPMs.Extreme Environments

Oil, gas, chemicals, and dust do not damage them easily.Precision Tools

Micrometers and measuring devices need very stable, hard balls.Heavy Loads

Tungsten carbide can carry more weight without deforming.Longevity

Using them saves money long-term due to fewer replacements.

When Should You NOT Use Tungsten Carbide Balls?

Even though they are excellent, tungsten carbide balls are not perfect for every situation. Avoid using them when:

Low-cost is top priority

Steel balls are cheaper for short-term use.You need super light weight

Ceramic balls are lighter, which is better in some high-speed or aerospace applications.Soft surface contact

Tungsten carbide is too hard for delicate materials and may cause damage.

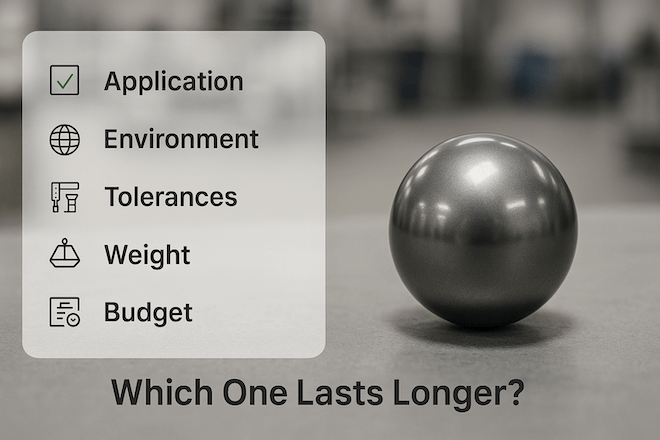

Tips for Choosing the Right Type

Before buying, consider these points:

What is the ball used for?

Will it face pressure, heat, or chemicals?

How long do you expect it to last?

Is precision important?

Is your project cost-sensitive or quality-focused?

If you need a ball that is strong, hard, and long-lasting, tungsten carbide is often the best choice.

마지막 생각

While steel balls and ceramic balls have their place, tungsten carbide balls offer the best balance of hardness, durability, and wear resistance.

They are especially useful when performance and precision matter most. If you want to avoid frequent replacements and ensure stable performance, they are worth the investment.

~에 다시 올리기, we offer custom tungsten carbide balls in various sizes and tolerances to fit your needs. Whether you’re in oil & gas, aerospace, medical, or industrial manufacturing, our expert team can help you choose the right grade.