텅스텐 카바이드 부싱 are widely used in industries like 채광, chemical processing, and 석유 및 가스 due to their outstanding hardness, 내마모성, 그리고 내구성.

Traditionally, tungsten carbide bushings are produced with a binder material, such as cobalt or nickel, to provide 강인함 and help hold the carbide grains together.

However, binderless tungsten carbide bushings have emerged as an alternative in certain applications. These bushings are made from pure tungsten carbide without the addition of a binder material.

This article explores when binderless tungsten carbide bushings make sense, their benefits, potential drawbacks, and ideal applications.

What Are Binderless Tungsten Carbide Bushings?

Binderless tungsten carbide bushings are made entirely of tungsten carbide without any metallic binder.

The result is a bushing that is incredibly hard and wear-resistant, but it lacks some of the flexibility and 강인함 that a binder can provide.

Key features of binderless tungsten carbide bushings:

100% tungsten carbide without any binder like cobalt or nickel

더 높은 경도 than traditional tungsten carbide bushings

Greater resistance to wear due to the absence of binder material

More brittle compared to standard tungsten carbide bushings

Higher density and improved 내마모성 at the cost of toughness

While binderless tungsten carbide bushings offer significant performance advantages in certain conditions, their brittleness can be a challenge in some applications.

Understanding when to use them is critical for maximizing their benefits.

Advantages of Binderless Tungsten Carbide Bushings

Binderless tungsten carbide bushings are an excellent choice in certain high-wear, high-stress applications. Their key advantages include:

Key benefits:

극심한 경도: Binderless tungsten carbide is one of the hardest materials known, making it highly resistant to abrasion and wear.

우수한 내마모성: Because they are free of binders, these bushings have a higher 밀도 and lower 다공성, reducing the chance of wear and tear from abrasive particles.

Improved thermal stability: Binderless bushings can withstand higher temperatures compared to those with cobalt or nickel binders.

Longevity: In environments with constant friction and abrasion, binderless bushings can outlast traditional tungsten carbide bushings, reducing downtime and maintenance costs.

These features make binderless tungsten carbide bushings especially useful in applications where wear is a significant concern, such as in pumps handling abrasive fluids.

Drawbacks of Binderless Tungsten Carbide Bushings

Despite their impressive 경도 그리고 내마모성, binderless tungsten carbide bushings have certain limitations. Understanding these limitations helps to determine when they are not the right choice.

Potential drawbacks:

Brittleness: The absence of a binder makes the material more brittle and prone to cracking under high impact or sudden stress.

Difficult machining: Binderless tungsten carbide is harder to machine, which can result in higher manufacturing costs and longer lead times.

더 적은 강인함: Compared to WC-Co or WC-Ni bushings, binderless tungsten carbide has lower toughness, which can be a problem in applications subject to vibration or mechanical shock.

Limited flexibility: The lack of binder means that these bushings may not perform well in applications where flexibility and impact resistance are important.

Given these drawbacks, binderless tungsten carbide bushings are best suited for certain conditions where extreme wear resistance outweighs the need for toughness or flexibility.

When Do Binderless Tungsten Carbide Bushings Make Sense?

Binderless tungsten carbide bushings are ideal in specific applications where their benefits can be fully utilized and their limitations do not pose a significant problem.

Here are some situations where binderless bushings make sense:

1). Ideal applications:

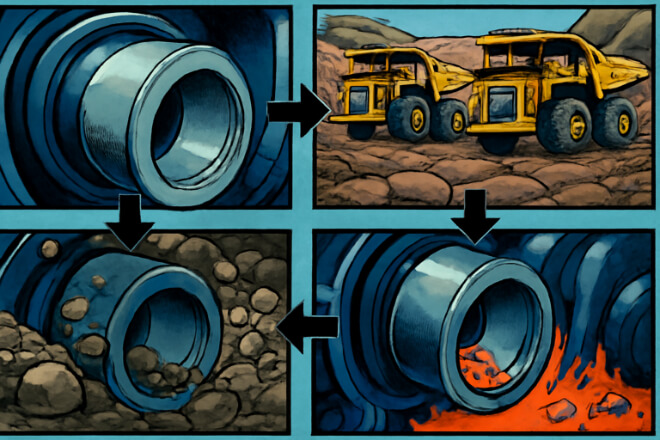

High-wear environments:

다음과 같은 산업에서 채광, dredging, and heavy machinery, where abrasion from rocks, sand, or slurry is constant, binderless tungsten carbide bushings can offer superior 내마모성.

Chemical processing:

In environments where high temperatures and corrosive substances are present, binderless bushings can provide long-lasting protection.

Pump systems:

When handling abrasive fluids that create high friction, such as slurry or cement, binderless tungsten carbide bushings are an excellent choice for increasing the lifespan of pumps.

High-speed applications:

In high-speed rotational equipment, where wear resistance is critical, binderless bushings can help improve performance and reduce friction.

Extreme temperature applications:

In scenarios where pumps or machinery are exposed to high temperatures and abrasives, the thermal stability of binderless tungsten carbide is a key advantage.

2). When not to use binderless bushings:

Impact-heavy applications:

If your equipment is subject to mechanical shock, vibration, or misalignment, the brittleness of binderless tungsten carbide can cause premature failure.

Flexibility needed:

For applications requiring a certain level of flexibility or toughness, binderless tungsten carbide may not be suitable due to its lower 강인함 compared to bindered versions.

Cost-sensitive applications:

The difficulty of machining binderless tungsten carbide can increase costs and lead times. In applications where cost is a significant concern, WC-Co or WC-Ni may be more economical.

Binderless Tungsten Carbide vs. Traditional Tungsten Carbide Bushings

To help you choose the best option for your application, let’s compare binderless tungsten carbide bushings with traditional tungsten carbide bushings (WC-Co and WC-Ni).

Comparison Table: Binderless vs. Traditional Tungsten Carbide Bushings

| Characteristic | Binderless WC | WC-Co (Cobalt Binder) | WC-Ni (Nickel Binder) |

|---|---|---|---|

| 경도 | 매우 높음 | 높은 | 높은 |

| 부식 저항성 | 낮음~중간 | 중간 | 매우 높음 |

| 강인함 | 낮은 | 높은 | 높은 |

| 내마모성 | 매우 높음 | 높은 | 높은 |

| 비용 | 높은 | 중간 | 중간 |

When to Choose Binderless Tungsten Carbide Bushings

Binderless tungsten carbide bushings are a top choice when durability, 내마모성, and high performance are crucial, and when the application does not involve excessive mechanical shock or vibration.

They are best suited for harsh abrasive environments, where high temperatures and minimal maintenance are priorities.

결론

Binderless tungsten carbide bushings offer superior hardness and wear resistance, making them ideal for specific applications in abrasive environments.

While they are highly effective in preventing wear, they may not be suitable for applications that require toughness or flexibility.

By considering the fluid properties, mechanical stress, and operational conditions, you can determine if binderless tungsten carbide bushings are the right choice for your equipment.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.