오늘날 제조 업계에서 지속가능성은 단순한 유행을 넘어 책임입니다. 많은 기업이 간과하는 중요한 영역 중 하나는 절삭 공구, 특히 텅스텐 카바이드로 제작된 절삭 공구의 재활용입니다.

기계 가공 작업을 하고 있다면 다음과 같은 궁금증이 있을 것입니다. 할 수 있다 텅스텐 카바이드 절단 도구 재활용이 가능할까?

간단히 말해서, 그렇습니다. 그 이점은 단순히 친환경적인 것 이상입니다. 텅스텐 카바이드 공구를 재활용하면 비용을 절감하고, 지속가능성 노력을 개선하며, 심지어 마모된 공구의 가치를 회복하는 데 도움이 될 수 있습니다.

이 글에서는 텅스텐 카바이드 공구 재활용이 어떻게 이루어지는지, 왜 중요한지, 그리고 이를 통해 기업이 어떤 이익을 얻을 수 있는지 알아보겠습니다.

텅스텐 카바이드 공구 재활용이 중요한 이유

텅스텐 카바이드는 희귀하고 값비싼 소재입니다. 매우 단단하고 내마모성—강력한 금속을 절단하는 데 적합합니다. 하지만 생산하는 데는 많은 에너지와 원자재가 필요합니다.

사용한 도구를 재활용하면 다음과 같은 이점이 있습니다.

환경 영향 감소

천연자원 채굴을 줄이세요

원자재 비용 절감

글로벌 지속 가능성 목표 지원

소규모 기계 공장이든 대규모 제조 시설이든, 재활용은 장기적인 툴링 전략의 일부가 되어야 합니다.

텅스텐 카바이드를 재활용할 수 있는 이유는 무엇입니까?

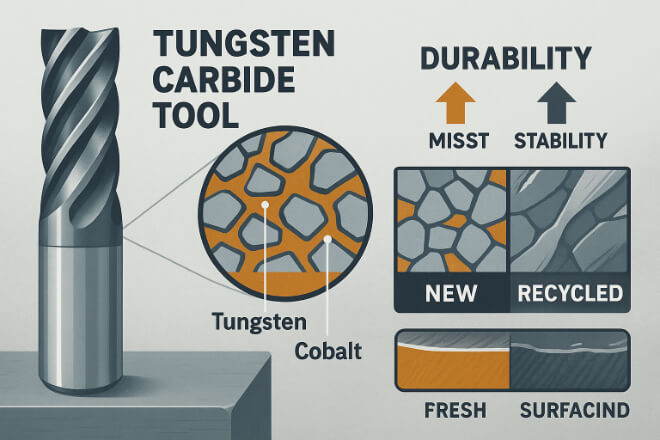

텅스텐 카바이드는 텅스텐과 금속 결합제(보통 코발트)로 만든 복합 소재입니다.

이러한 원소들은 매우 귀중하며 쉽게 분해되지 않습니다. 도구가 마모된 후에도 재료는 여전히 회수하여 재사용할 수 있습니다.

주요 재활용 특징:

내구성: 강철과 달리 카바이드는 사용 후에도 핵심 구조를 잃지 않습니다.

높은 텅스텐 함량: 일반적으로 중량 기준으로 70–97% 텅스텐입니다.

안정적인 재활용 과정: 화학적 또는 열적 방법을 통해 정제됩니다.

카바이드는 구조상 다른 많은 공구 소재보다 재활용성이 더 뛰어납니다.

재활용 가능한 도구 유형

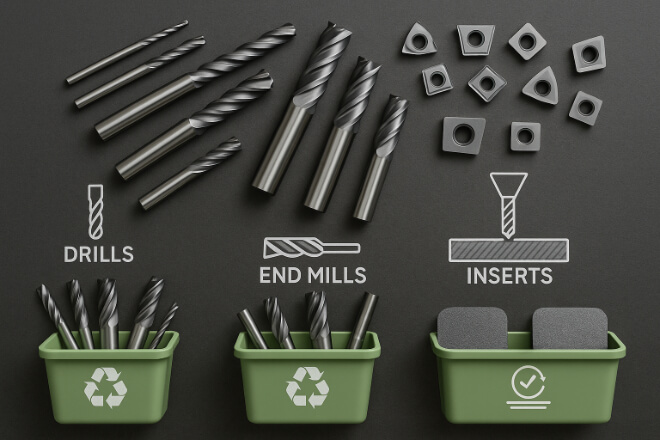

모든 절삭 공구가 재활용에 적합한 것은 아니지만, 대부분의 초경 공구와 초경 인서트는 재활용 가능합니다. 여기에는 다음이 포함됩니다.

드릴

리머

터닝 인서트

밀링 인서트

낡은 공백

오염이 최소화된 공구(코팅이나 납땜 접합부 등)는 재활용이 더 쉽습니다. 일부 공급업체는 공정에 따라 혼합된 로트를 재활용하기도 합니다.

재활용 프로세스 작동 방식

텅스텐 카바이드 재활용 과정이 일반적으로 어떻게 진행되는지 간략하게 설명하면 다음과 같습니다.

1단계: 수집 및 분류

중고 초경 공구를 수거하고 분류합니다. 여기에는 오염 여부 확인, 공구 종류 구분, 그리고 초경이 아닌 소재 제거가 포함됩니다.

2단계: 분쇄 및 분쇄

도구를 작은 입자나 가루로 부수어 정제 과정을 준비합니다.

3단계: 화학 또는 열 처리

두 가지 주요 방법이 사용됩니다.

아연 재활용 공정(텅스텐 카바이드의 직접 재사용을 위한)

화학 정제(순수한 텅스텐과 코발트를 회수하기 위해)

4단계: 분말 회수 및 재사용

최종 분말은 품질 저하가 거의 없거나 전혀 없이 새로운 초경 공구를 만드는 데 재사용될 수 있습니다.

이 공정을 통해 최대 95% 소재 회수가 가능하며 새로운 텅스텐 채굴의 필요성이 크게 줄어듭니다.

제조업체의 이점

초경 공구 재활용은 단순히 친환경적인 측면만은 아닙니다. 이는 귀하의 사업에 실질적인 이점을 제공합니다.

1) 비용 절감

중고 공구는 공급업체나 재활용 파트너에게 다시 판매할 수 있는 경우가 많습니다. 또한, 향후 공구 구매 시 크레딧을 받으실 수도 있습니다.

2) 안정적인 자재 공급

재활용된 카바이드는 공급망 문제와 가격 급등의 영향을 받는 원자재 채굴에 대한 의존도를 줄여줍니다.

3) 더 나은 ESG 성과

현재 많은 회사가 환경, 사회, 지배구조(ESG) 지표를 추적하고 있습니다.

재활용은 환경 영향과 기업의 책임과 관련된 목표를 지원합니다.

4). 더 깨끗한 작업 공간

정기적으로 사용한 도구를 모아 재활용하면 작업 공간을 더 정돈하고 폐기물을 줄이는 데 도움이 됩니다.

재활용 파트너 선택

적합한 재활용 파트너와 협력하는 것이 필수적입니다. 다음과 같은 조건을 갖춘 회사를 찾아보세요.

텅스텐 카바이드 재활용 전문

픽업 서비스 또는 하차 장소를 제공하세요

재활용 또는 재료 회수 인증서 제공

환매 또는 신용 프로그램 제공

코팅된 도구는 어떤가요?

TiAlN, TiN 또는 DLC 코팅이 된 도구 등 코팅된 도구도 재활용이 가능합니다.

그러나 재활용업체의 방법에 따라 처리 전에 코팅을 제거해야 할 수도 있습니다.

일부 재활용업체는 별도의 처리 없이 코팅을 처리할 수 있는 장비를 갖추고 있으므로 해당 업체의 역량을 확인하는 것이 좋습니다.

도구 재활용에 대한 일반적인 오해

몇 가지 오해를 해소해 보겠습니다.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elittellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

| 신화 | 현실 |

|---|---|

| 재활용은 비용이 많이 든다 | 대부분의 재활용업체는 무료 수거 서비스를 제공하거나 폐기물에 대한 비용을 지불하기도 합니다. |

| 대기업만이 재활용할 수 있다 | 작은 매장도 참여 가능 |

| 재활용 재료는 품질이 낮습니다 | 최신 공정을 통해 고급 도구에 사용되는 고순도 분말을 회수합니다. |

| 시간 낭비야 | 많은 파트너들이 재활용을 빠르고 쉽게 만들어줍니다. |

초경 공구 재활용을 위한 모범 사례

재활용 프로그램을 최대한 활용하려면:

재료 유형(초경 대 HSS)별로 도구 정렬

오염을 방지하려면 도구를 깨끗하고 건조하게 유지하세요.

스크랩 용기에 명확하게 라벨을 붙이세요

성과 통찰력을 위해 도구 사용 및 수익을 추적하세요

도구 공급업체와 협력하여 폐쇄 루프 프로세스를 만드십시오.

이런 습관을 업무 흐름에 접목하면 재활용을 환경과 사업적 성과를 모두 향상시키는 일상으로 바꿀 수 있습니다.

재활용 vs. 재생

재활용만이 유일한 방법은 아닙니다. 마모된 공구를 다시 날카롭게 하고 재코팅하는 재생(Reconditioning)은 공구 수명을 연장하는 또 다른 방법입니다.

많은 초경 공구는 완전한 재활용이 필요하기 전까지 2~3회 정도 재조정이 가능합니다.

| 옵션 | 가장 적합한 | 주요 이점 |

|---|---|---|

| 리컨디셔닝 | 도구는 여전히 좋은 상태입니다 | 더 낮은 비용으로 도구 수명을 연장합니다 |

| 재활용 | 마모되거나 깨진 도구 | 재료 회수 및 폐기물 감소 |

팁: 낡은 도구를 버리기 전에 공급업체에 수리를 맡기는 것이 좋은지 물어보세요.

환경 영향에 대한 간략한 설명

1,000kg의 카바이드 스크랩을 재활용하는 것의 환경적 이점을 살펴보겠습니다.

| 영향 영역 | 예상 절감액 |

|---|---|

| 원료 추출 | 60–70% 감소 |

| 에너지 사용 | 채굴보다 50–60% 적은 에너지 |

| CO₂ 배출량 | 30–40% 저배출 |

| 폐기물 감소 | 수천 개의 도구가 매립지에서 다른 곳으로 옮겨졌습니다. |

이러한 수치는 도구 재활용과 같은 작은 변화가 얼마나 강력한지 보여줍니다.

마지막 생각

텅스텐 카바이드 절삭 공구는 내구성이 뛰어난 것으로 알려져 있지만 영원히 사용할 수는 없습니다.

수명이 다하면 재활용하는 것이 기업과 환경을 위해 현명한 선택입니다.

비용 절감, 지속 가능성 개선 또는 단순히 재료의 보다 스마트한 활용을 원하든, 카바이드 공구 재활용은 실질적인 가치를 제공합니다.

시작하려면 지금 바로 절삭 공구 공급업체 또는 재활용 파트너와 상담하세요. 프리미엄 공구와 재활용 지원을 모두 제공하는 공급업체를 찾고 계시다면 다음 웹사이트를 방문하세요. 레톱즈.