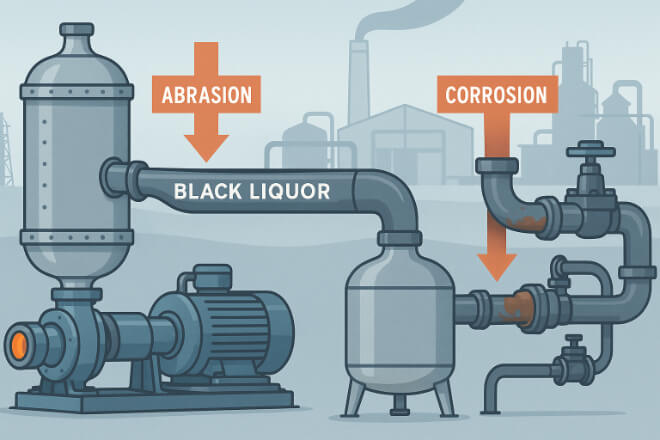

펄프, 제지 및 흑액 서비스 분야의 과제

연마성 펄프 섬유는 표준 씰을 빠르게 마모시킵니다.

펄핑의 부산물인 흑액은 알칼리성이 매우 강하고 부식성이 강합니다.

화학 물질 회수 보일러와 증발기의 고온은 장비에 스트레스를 줍니다.

계속적인 운영으로 인해 가동 중지로 인해 비용이 많이 들고 업무에 지장이 발생합니다.

스테인리스 스틸이나 탄소 흑연 씰은 이런 조건에 충분히 강하지 않은 경우가 많습니다. 카바이드 씰 링 필요한 강도와 안정성을 제공합니다.

카바이드 씰 링이 최고의 선택인 이유

카바이드는 다이아몬드만큼 단단합니다. 펄프 섬유와 흑액 속 고체 입자로 인한 긁힘과 마모에 강합니다.

2). 부식 저항성

니켈 결합 카바이드는 알칼리 및 화학 물질에 대한 내성이 매우 강해 흑액 시스템에 적합합니다.

3) 강도 및 충격 저항성

코발트 결합 카바이드는 믹서와 펌프의 압력 변화와 기계적 충격 부하를 처리합니다.

4) 열 안정성

카바이드 링은 표백 및 회수 과정에서 발생하는 고온에서도 성능을 유지합니다.

5) 더 긴 서비스 수명

마모와 부식이 줄어들면 교체 횟수가 줄어들고 유지 관리 비용도 낮아집니다.

펄프 및 제지 가공 분야의 응용 분야

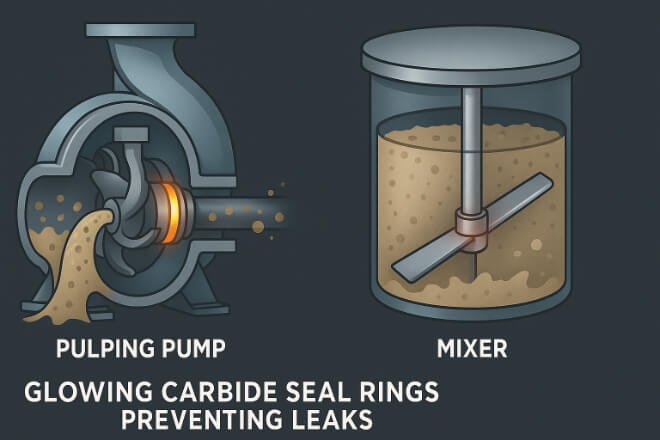

1). 펄핑 펌프

카바이드 씰 링 연마 펄프 혼합물을 이송하는 펌프의 누출을 방지합니다.

2) 정제기 및 믹서기

지속적인 혼합과 정제에는 마찰을 줄이고 마모를 방지하는 씰이 필요합니다.

3) 표백 시스템

부식성 표백 화학물질에서 카바이드 링은 안정적인 밀봉을 유지합니다.

블랙 리커 서비스 응용 프로그램

1). 흑액 증발기

카바이드 씰은 농축되고 부식성이 있는 흑액을 처리하는 증발기의 누출을 방지합니다.

2). 회수 보일러

씰 링은 높은 열과 화학적 공격의 조합을 견뎌냅니다.

3). 화학 회수 회로

내구성이 뛰어난 카바이드 링은 흑액을 재활용하는 시스템의 안정성을 향상시킵니다.

펄프 및 제지 산업의 이점

| 혜택 | 설명 |

|---|---|

| 연장된 서비스 수명 | 마모성 펄프와 부식성 액체에 강해 교체 횟수를 줄입니다. |

| 다운타임 감소 | 씰 고장이 적으면 장비가 계속 작동하고 생산량이 안정됩니다. |

| 향상된 안전성 | 작업자에게 해를 끼칠 수 있는 뜨겁고 부식성이 있는 검은 액체의 누출을 방지합니다. |

| 비용 효율성 | 유지관리가 덜 필요하고 교체 횟수도 줄어들어 총 소유 비용이 낮아집니다. |

| 프로세스 신뢰성 | 안정적인 밀봉으로 일관된 펄프 및 종이 생산 품질을 보장합니다. |

사례 연구

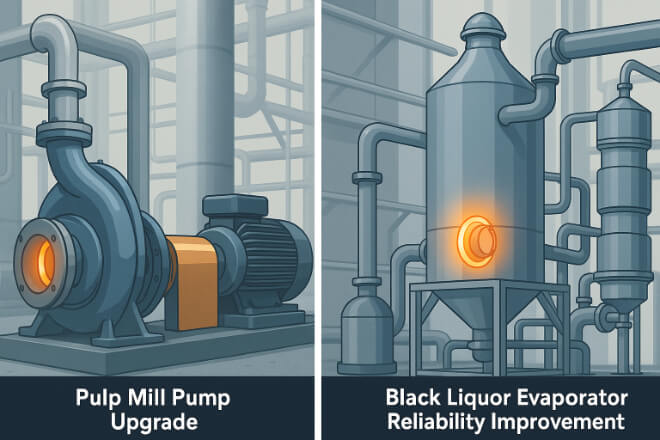

1). 펄프 공장 펌프 업그레이드

펄프 공장에서는 스테인리스 스틸 씰을 니켈 결합 카바이드 링으로 교체했습니다. 그 결과, 40%의 씰 수명이 두 배로 늘어났고, 예상치 못한 유지 보수도 감소했습니다.

2). 흑액 증발기 신뢰성

한 제지 공장에서는 흑액 증발기에 카바이드 링을 사용했습니다. 그 결과, 누출이 감소하고 환경 규정 준수가 개선되었으며 운영 비용도 절감되었습니다.

올바른 카바이드 씰 링을 선택하는 방법

1). 바인더 종류

부식성 흑액 및 표백 화학물질을 위한 니켈 결합 카바이드입니다.

교반기 및 펄핑 펌프의 충격 하중을 위한 코발트 결합 카바이드.

2) 표면 마감

광택이 나는 카바이드 표면은 회전 장비의 마찰과 마모를 줄여줍니다.

3). 작동 조건

등급을 선택할 때 온도, 압력, 화학물질 노출을 고려하세요.

4). 공급업체 전문성

펄프 및 제지 분야에 경험이 있는 ISO 인증 공급업체를 선택하세요.

유지 관리 및 교체 전략

계획된 정지 중에 균열, 홈 또는 부식이 있는지 씰을 검사합니다.

생산 손실을 방지하려면 누출이 발생하기 전에 마모된 링을 교체하세요.

중요한 펌프와 믹서에 사용할 여분의 카바이드 씰을 비축해 두세요.

비용과 환경 영향을 줄이기 위해 사용된 카바이드 부품을 재활용합니다.

비용 및 ROI 고려 사항

초기 비용: 표준 씰보다 높습니다.

비용 절감: 누출과 가동 중단이 줄어들어 수익성이 향상됩니다.

투자수익률(ROI): 더 긴 서비스 수명과 향상된 신뢰성으로 인해 투자가 정당화됩니다.

환경 및 안전 이점

흑액 누출을 방지하면 강, 지하수, 그리고 공장 근로자를 보호할 수 있습니다. 카바이드 씰은 공장이 환경 규정을 준수하고 안전한 작업 환경을 유지하는 데 도움이 됩니다.

결론

카바이드 씰 링은 펄프, 제지, 흑액 처리에 필수적입니다. 경도, 내식성, 내구성이 뛰어나 까다로운 환경에 최적의 선택입니다.

의사결정권자에게 카바이드 씰은 고장 감소, 유지 관리 비용 절감, 안전성 향상, 안정적인 생산 품질을 보장합니다. 이는 펄프 및 제지 산업에서 경쟁력을 유지하는 데 중요한 요소입니다.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.