텅스텐 카바이드 부싱 are known for their high hardness, wear resistance, and durability.

They are used in pumps, compressors, valves, and other heavy-duty machinery where precision and long life are essential.

But even the best tungsten carbide will eventually wear out if it faces extreme friction, heat, or corrosion.

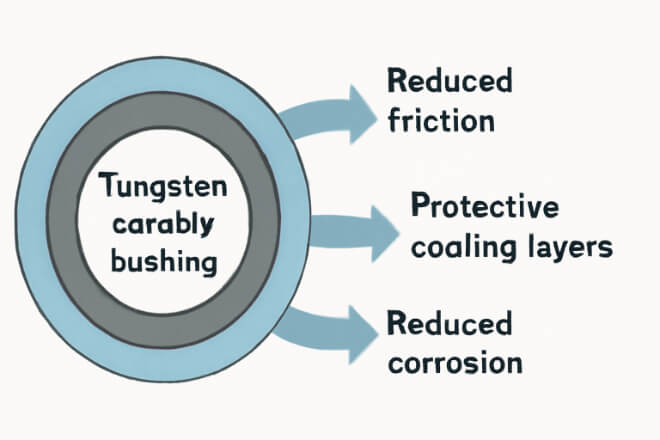

To extend service life and reduce maintenance, manufacturers apply special coatings and surface treatments.

These processes enhance performance by adding extra protection layers against wear, oxidation, and erosion.

Understanding which coating or treatment fits your application can save time, cost, and equipment downtime.

Why Coatings and Surface Treatments Matter

Even though tungsten carbide is one of the hardest engineering materials, it is still vulnerable in specific environments:

High-temperature oxidation can reduce surface strength.

Corrosive fluids may attack the cobalt or nickel binder.

Repeated contact or vibration can cause micro-cracks.

Surface coatings and treatments help solve these problems by:

Reducing friction and heat.

Improving 내식성.

Enhancing hardness and fatigue life.

Preventing binder leaching in chemical exposure.

In short, coatings and treatments act as armor that allows tungsten carbide bushings to perform longer in tough industrial conditions.

Common Coating Types for Tungsten Carbide Bushings

Different coatings are used depending on operating environment, speed, and temperature. Below is a comparison of the most widely used coating types.

| 코팅 유형 | Deposition Method | 주요 이점 | 이상적인 응용 프로그램 |

|---|---|---|---|

| TiN(질화티타늄) | PVD or CVD | High hardness, low friction, gold-colored finish | Pump bushings, valve seats |

| TiAlN(티타늄 알루미늄 질화물) | PVD | Excellent oxidation resistance, works at high temperature | High-speed compressors, turbines |

| CrN (Chromium Nitride) | PVD | Corrosion resistance and reduced sticking | Chemical or marine pumps |

| DLC(다이아몬드 유사 탄소) | Plasma CVD | Very low friction, extreme wear resistance | Precision bearings, dry lubrication systems |

| WC-Co HVOF Spray | Thermal spray (HVOF) | Thick coating layer with high wear protection | Heavy-duty pump sleeves, industrial rollers |

Each coating type changes surface behavior. For example, DLC makes tungsten carbide almost friction-free, while CrN helps in corrosive or humid environments.

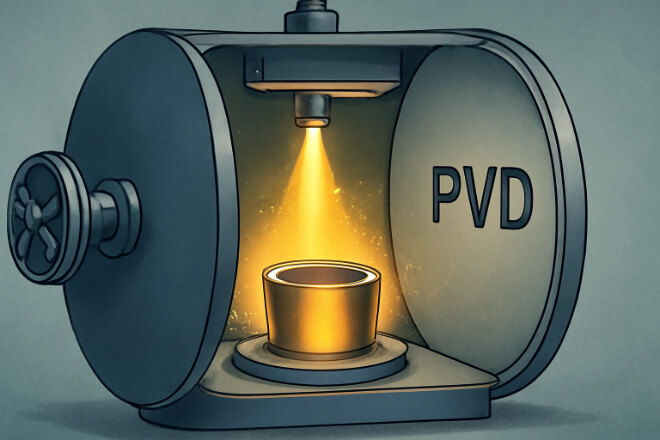

Physical Vapor Deposition (PVD) Coatings

PVD coatings such as TiN, TiAlN, or CrN are applied in a vacuum chamber. They create a thin (1–5 µm) but extremely hard film on the surface.

1). 장점:

Uniform coating thickness

Excellent adhesion to tungsten carbide

High wear and oxidation resistance

2). Applications:

Ideal for precision bushings, bearing sleeves, and high-speed shafts where lubrication may be limited.

PVD coatings also improve surface smoothness, lowering the coefficient of friction and reducing heat buildup.

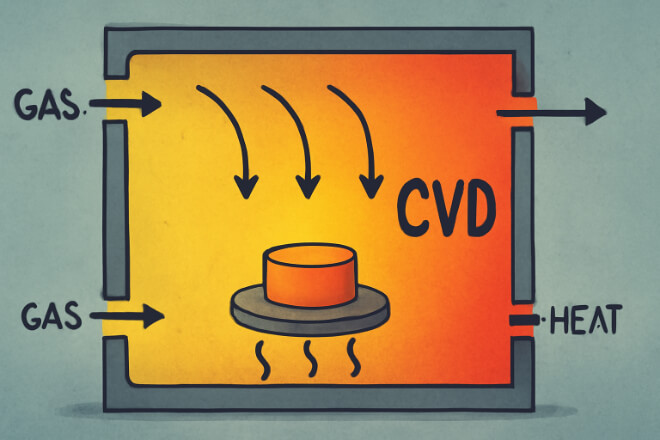

Chemical Vapor Deposition (CVD) Coatings

CVD coatings form under high temperature (900–1100°C) in a reactive gas atmosphere.

They are slightly thicker (5–15 µm) than PVD coatings and offer superior adhesion.

1). 장점:

Very dense coating

Better chemical and 내식성

Suitable for high-temperature service

2). Common Materials:

TiC (Titanium Carbide), TiN, and TiCN (Titanium Carbonitride).

3). Applications:

Used on tungsten carbide bushings in chemical processing and gas compression systems, where corrosion and chemical leaching are major risks.

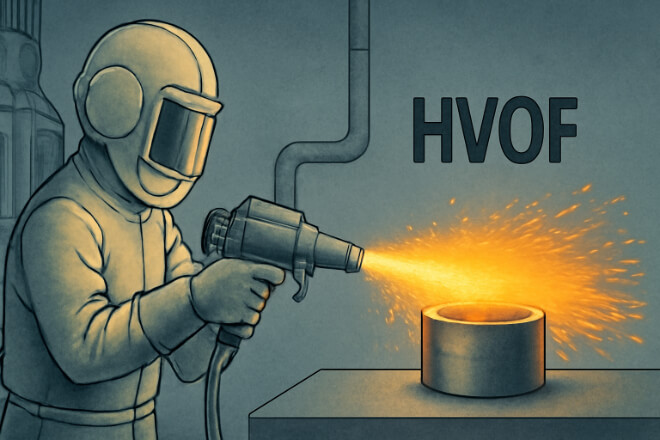

Thermal Spray Coatings

When thicker protection layers are required, thermal spray coatings are the go-to option. The most common is HVOF (High Velocity Oxy-Fuel) coating.

This process sprays molten WC-Co or WC-Ni particles onto the bushing surface, forming a dense, bonded outer layer.

1). 장점:

Coating thickness up to 300 µm

Excellent impact and erosion resistance

Suitable for repair and refurbishment

2). Applications:

Heavy-duty bushings in pumps, slurry systems, and mining tools benefit most from HVOF coatings.

Diamond-Like Carbon (DLC) Coating

DLC coating gives the tungsten carbide bushing an extremely hard, low-friction surface.

It combines the advantages of diamond hardness with graphite’s lubricity.

Key Benefits:

Friction coefficient as low as 0.05

Excellent wear and fatigue resistance

Reduces need for lubrication

Provides corrosion protection

DLC-coated bushings are used in aerospace, automotive, and precision machinery, where clean operation and low heat generation are important.

코팅을 넘어선 표면 처리

Apart from coatings, several surface treatments can extend tungsten carbide bushing life by improving adhesion, toughness, or surface chemistry.

| Treatment Type | Process Description | 주요 이점 | Best Used In |

|---|---|---|---|

| Polishing / Lapping | Removes surface irregularities and improves finish. | Lowers friction, improves seal contact. | Seal bushings, high-speed shafts. |

| Plasma Nitriding | Diffuses nitrogen ions into the binder metal. | Increases surface hardness and fatigue resistance. | Pump housings, shaft sleeves. |

| Nickel Plating | Electroplated nickel layer adds corrosion protection. | Resists chemical and saltwater attack. | Marine and chemical environments. |

These treatments are often combined with coatings to achieve the best performance balance — for example, DLC over polished surfaces or HVOF over plasma-treated bases.

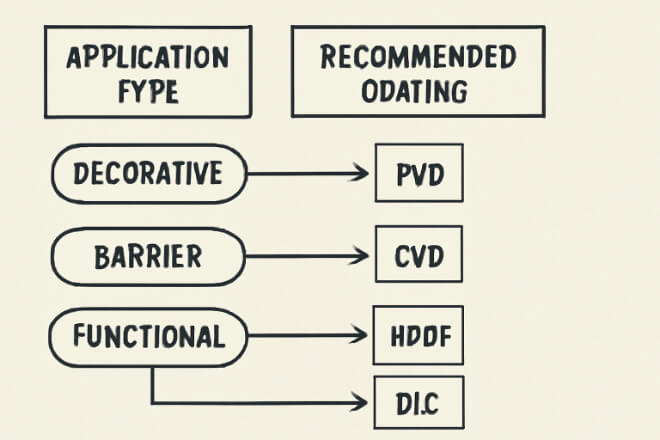

Choosing the Right Coating or Treatment

Selecting the right protection depends on your operating environment and failure mode.

Below are simple guidelines:

If wear is the main issue: Use DLC or HVOF WC-Co coatings.

If corrosion is dominant: Use CrN or Nickel plating.

If temperature is high: Use TiAlN or TiC coatings.

If impact or shock occurs: Use thicker HVOF layers.

If precision and smoothness are key: Apply PVD TiN with fine polishing.

A professional supplier can help tailor both coating material and thickness based on your process media, load, and lubrication.

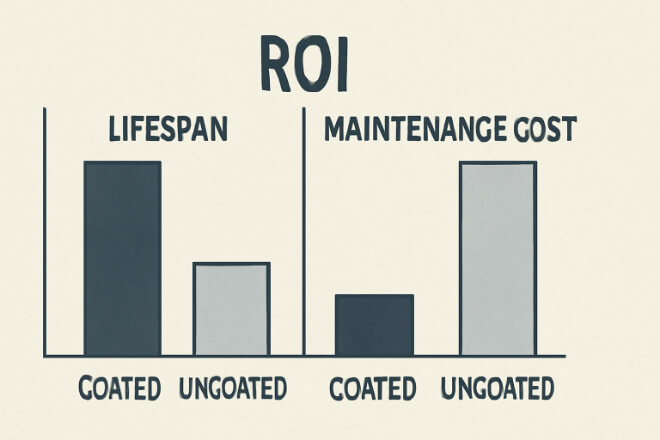

Economic Benefits of Coatings

While coatings add upfront cost, they significantly reduce total ownership costs:

Longer service intervals mean fewer replacements.

Lower friction saves energy and improves efficiency.

Better corrosion resistance reduces unplanned downtime.

Improved sealing leads to fewer leaks and maintenance calls.

Most industries report a 30–50% increase in bushing life with the correct coating system.

결론

The right coating or treatment can transform a standard tungsten carbide bushing into a high-performance, long-life component.

By combining tough carbide cores with advanced coatings like DLC, TiN, or HVOF, manufacturers can handle more aggressive operating conditions — from abrasive slurries to hot gases.

For decision-makers, investing in coated or treated bushings means lower life-cycle cost, better reliability, and higher uptime.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.