When new equipment is being started — a pump, a compressor, or a mixer — the mechanical seal is often the last thing people check. Yet it’s one of the first components to fail when something isn’t quite right.

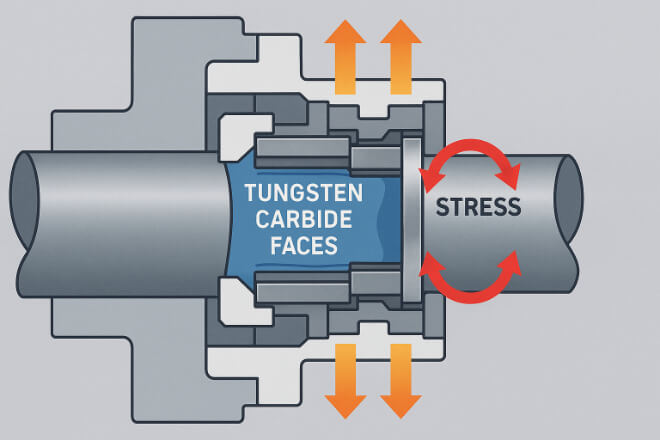

Carbide-faced seals, especially those using tungsten carbide or silicon carbide, are strong and 내마모성, but they’re not indestructible.

Small mistakes made during installation or commissioning can lead to leakage, vibration, or total seal failure before the machine even completes its first week of service.

That’s why having a clear, practical commissioning checklist matters.

This article walks through the key areas you need to verify — alignment, flush system, and face load — with a few real-world examples from the field to show how each step affects reliability.

Why Commissioning Matters for Carbide-Faced Seals

Carbide seals are built to handle hard conditions: abrasive slurries, high pressures, and continuous operation.

But the same 경도 that gives them long life also makes them brittle under stress.

If alignment is slightly off, or if the flush line isn’t working as designed, that stress concentrates on one edge of the seal.

The result? Micro-cracks, chipping, or uneven wear that leads to early leakage.

A short commissioning step — maybe an extra 30 minutes — can prevent downtime that costs thousands later.

It’s not just about checking boxes; it’s about protecting your investment.

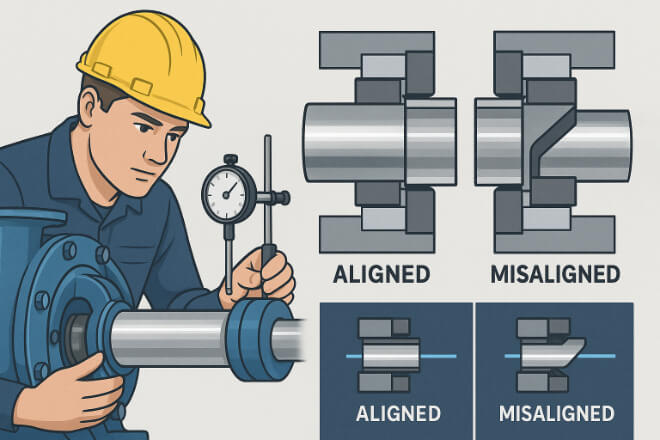

Step 1: Alignment Check — Avoiding Edge Loading

If the seal isn’t square with the shaft, everything else fails sooner or later. Alignment problems create edge loading — where one part of the carbide face carries more load than the rest.

1). What to Check

Shaft runout must be within spec (typically under 0.05 mm).

Seal gland should be square to the shaft.

Stationary and rotating faces should make even contact across the surface.

2). Why It Matters

Uneven contact produces local hot spots. For hard materials like tungsten carbide, that can quickly lead to cracking.

Once a chip forms, it usually spreads, and the seal starts leaking.

3). Field Tip

Before startup, rotate the shaft slowly by hand. Apply a thin coat of marking dye on the seal face — if the contact is even, you’ll see a full, uniform circle.

If it’s uneven, you’ll know before the machine ever spins at full speed.

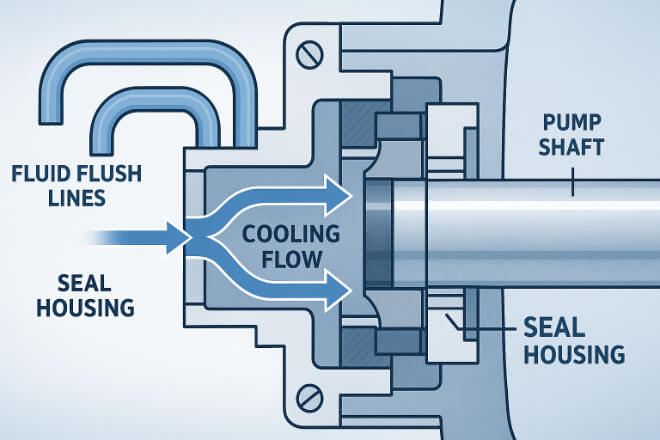

Step 2: Flush System — Managing Heat and Cleanliness

A flush line isn’t just a pipe with fluid running through it — it’s what keeps the seal faces cool, clean, and lubricated.

Without proper flow or pressure, carbide faces can overheat or run dry, leading to severe scoring or cracking.

1). What the Flush System Does

Carries away frictional heat from the seal faces.

Keeps out dirt and solid particles.

Maintains a thin, stable fluid film between the faces.

2). Checklist

| 매개변수 | Recommended Range | 목적 |

|---|---|---|

| Flush flow rate | Follow API 682 Plan (e.g., 11, 32) | Removes heat and particles |

| Fluid cleanliness | ISO 4406 below 18/16/13 | Prevents abrasion on faces |

| Pressure differential | 0.1–0.3 bar above seal chamber | Ensures positive flow |

| Temperature control | Below 80°C typical | Prevents thermal distortion |

3). Field Example

At one pulp and paper mill, an API Plan 32 flush was running below the recommended flow.

The result was hot spots on the tungsten carbide ring — cracks formed in less than two weeks. After adjusting the flow and adding a strainer, seal life tripled.

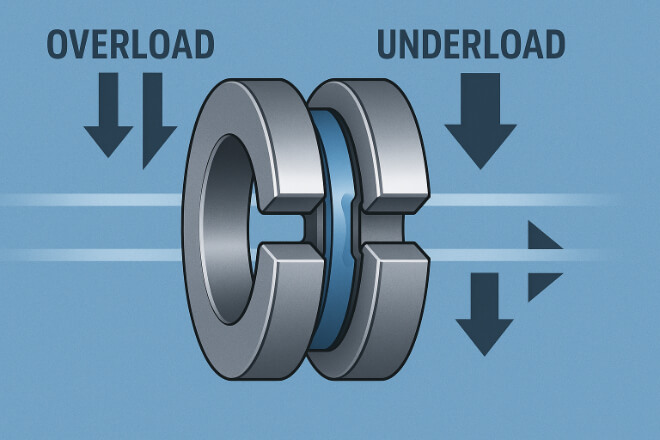

Step 3: Face Load — Getting the Pressure Right

The face load (the closing force between faces) needs to be just enough to seal — no more, no less.

Too light, and it leaks. Too heavy, and you’ll see overheating and rapid wear.

Carbide faces are unforgiving in this area — excessive force can lead to surface fracture, while underloading causes dry contact.

1). How to Get It Right

Set spring torque exactly per the manufacturer’s spec.

Use the correct balance ratio (normally 0.65–0.75 for high-speed seals).

Verify static face contact pressure if possible (around 5–10 kg/cm²).

2). Symptoms of Wrong Face Load

| 상태 | Visible Symptom | Likely Cause |

|---|---|---|

| Too low | Weeping or leakage | Weak spring, low differential pressure |

| Too high | 화상 자국이나 변색 | Excess compression |

| Uneven | Partial wear zone | Misalignment or uneven gasket compression |

3). Field Example

A fertilizer plant had recurring seal leaks on a process compressor. The root cause: over-tightened springs that doubled the design load.

After correcting the preload, the next set of seals lasted more than a year without issue.

Step 4: Final Checks Before Startup

This is the moment before you press the start button — where a quick double-check can save hours of troubleshooting later.

1). Checklist Before Running

Recheck shaft alignment and runout.

Confirm correct flush flow and pressure.

Verify rotation direction and coupling tightness.

Make sure the seal chamber is vented (no trapped air).

Pressurize slowly while watching for leaks.

Document everything — torque readings, flush pressure, temperature — and file it with the startup report. If something goes wrong later, that data becomes gold.

Step 5: Monitor the First Few Hours

Most seal problems appear during the first hours after startup. If the seal survives the break-in, it usually lasts a long time.

1). What to Watch

Small, steady leakage (a few drops/hour is fine)

Stable flush pressure and flow

Seal chamber temperature rise

Any unusual vibration or noise

2). Field Example

A food plant installed new tungsten carbide seals but skipped early monitoring.

After a few hours, one set overheated due to restricted flush flow. Once fixed, the next batch ran for over a year without a single leak.

Quick Reference — Commissioning Steps

| Step | Goal | Key Check |

|---|---|---|

| Alignment | Even face loading | Runout < 0.05 mm |

| Flush System | Control temperature, cleanliness | Flow, pressure, ISO code |

| Face Load | Proper contact pressure | Spring torque as per spec |

| Final Check | Ready for operation | Alignment, flush, venting |

| Startup Monitoring | Confirm stable operation | Leakage, temp, vibration |

피해야 할 일반적인 실수

| Mistake | 무슨 일이 일어나는가 |

|---|---|

| Ignoring shaft runout | Edge chipping and vibration |

| Wrong flush direction | Overheating or dry run |

| Overloaded spring | Excess wear and friction |

| Trapped air in seal chamber | Instant failure on startup |

| No early monitoring | Missed first signs of trouble |

Each one of these is preventable with a few minutes of attention during commissioning.

결론

Carbide-faced mechanical seals can easily run for years — but only if they start their life correctly.

Good alignment, proper flush setup, and correct face load are what keep them running cool and tight.

For plant managers and reliability engineers, the difference between a 6-month seal life and a 3-year seal life often comes down to the quality of commissioning.

A bit more care at startup means a lot less downtime later.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.