Tungsten carbide (WC) bushings are used in pumps, compressors, and industrial machines because they resist wear and work well under heavy load.

But they can still fail early when misalignment or poor clearance is present. These two problems look similar, but their causes and solutions are very different.

This guide explains how to tell misalignment failures from poor-clearance failures and how to prevent both.

Why Misalignment and Clearance Are Critical for WC Bushings

Misalignment and improper clearance create uneven forces on the bushing.

Tungsten carbide is hard but brittle, so concentrated loads can cause cracks, scoring, or out-of-round wear. Understanding these two failure modes helps operators diagnose problems quickly.

How Each Factor Impacts the Bushing

| 요인 | Impact on Bushing |

|---|---|

| Misalignment | Uneven loading, tilted shaft, one-sided wear |

| Poor Clearance | Excess friction, heat buildup, scoring |

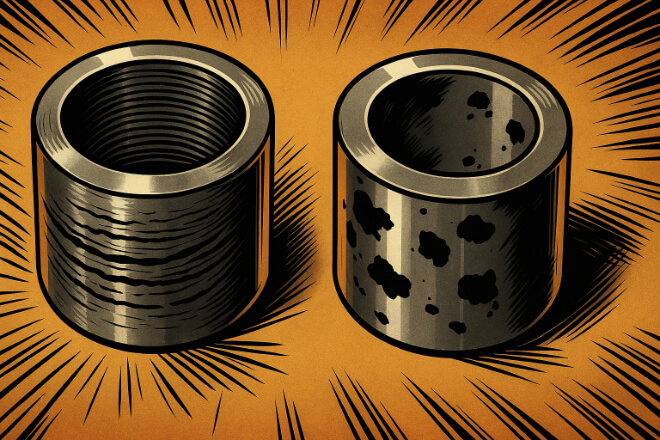

Common Symptoms of Misalignment in WC Bushings

Misalignment happens when the shaft centerline is not aligned with the housing centerline. Even a small offset can cause heavy wear on one side of the bushing.

1). Typical Misalignment Warning Signs

Wear marks on a single side of the bore

Out-of-round or elliptical wear pattern

Vibration increases during startup

Localized heat marks where load is highest

Cracks forming at the thin edge of the bushing

2). Visual Clues Inside the Bushing

| Observation | Indication |

|---|---|

| One-sided polishing | Shaft is leaning or offset |

| Diagonal scoring inside bore | Angular misalignment |

| Local hot spots | High-pressure contact zone |

Common Symptoms of Poor Clearance in WC Bushings

Clearance refers to the gap between the shaft and the bushing bore. If the clearance is too small, friction increases, heat rises, and surface damage occurs. If the clearance is too large, vibration and instability appear.

1). Signs of Poor (Too Tight) Clearance

Uniform scoring around the full circumference

Burn marks or discoloration from heat

Rapid wear on both the shaft and bushing

Higher torque or power draw

2). Signs of Poor (Too Loose) Clearance

Vibration at different speeds

Shaft movement causing instability

Random wear patches rather than continuous scoring

3). Clearance Problem Indicators

| Symptom | Likely Cause |

|---|---|

| Even wear all around | Clearance too tight |

| Light random wear | Clearance too large |

| Burn marks | Overheating from friction |

How to Tell Misalignment from Poor Clearance

While both problems cause wear, the pattern tells the story.

Misalignment produces uneven wear, while clearance problems produce uniform or random patterns depending on whether the clearance is too tight or too large.

1). Key Diagnostic Differences

| Failure Pattern | Misalignment? | Poor Clearance? |

|---|---|---|

| One-sided wear | 예 | No |

| Uniform full-contact wear | No | Yes (too tight) |

| Random patches | No | Yes (too loose) |

| Diagonal lines | 예 | No |

| Burn marks | Possible | Common |

2). Quick Rule of Thumb

Uneven = misalignment

Even = clearance issue

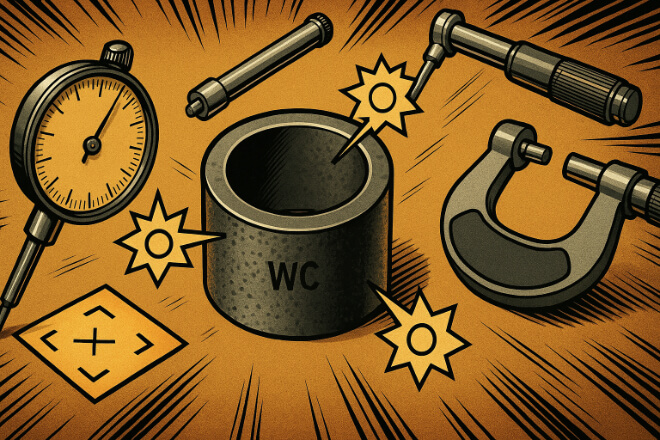

Measurement Methods to Confirm Misalignment or Poor Clearance

To diagnose correctly, measurements must be taken on both the shaft and housing.

1). Key Measurement Tools

Dial indicator

Bore gauge

마이크로미터

Laser alignment system

Roundness tester

2). What to Measure

| Measurement | What It Shows |

|---|---|

| Shaft concentricity | Misalignment of shaft centerline |

| Bore roundness | Distortion from stress or misalignment |

| Clearance gap | Whether clearance is too tight or too loose |

| Shaft runout | Dynamic misalignment |

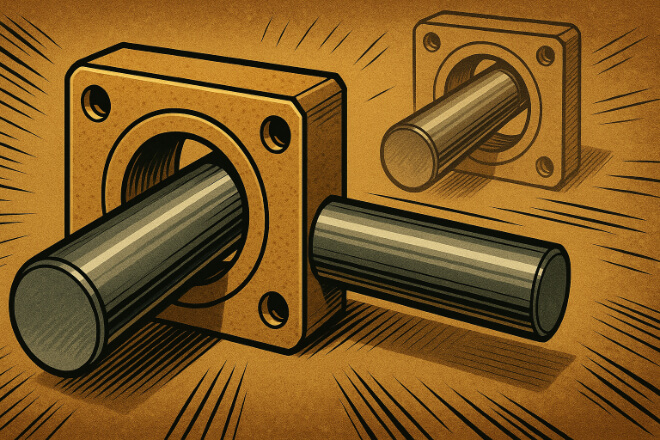

Preventing Misalignment in WC Bushing Systems

Reducing misalignment extends the life of both shaft and bushing.

1). Best Practices

Ensure housing and shaft machining accuracy

Use proper alignment tools during installation

Avoid forcing the bushing into a distorted bore

Check foundation and machine frame stiffness

Recheck alignment after heat cycles

2). Why This Matters

Misalignment increases point-loading, which WC material cannot absorb. Fixing alignment issues often eliminates 50–70% of early WC bushing failures.

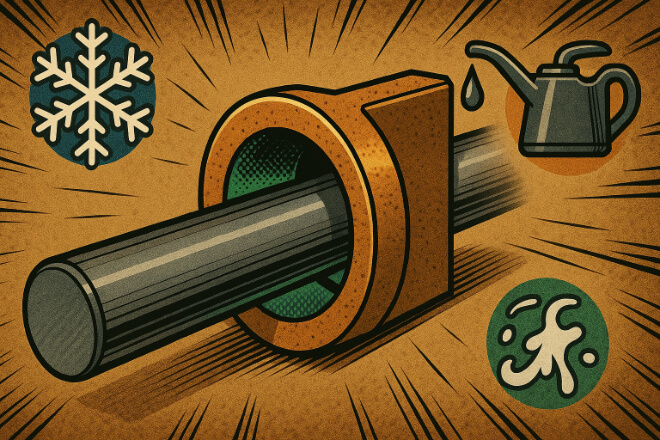

Preventing Clearance Problems in WC Bushing Systems

Selecting and maintaining correct clearance is essential for lubrication, heat control, and stability.

1). How to Avoid Clearance Issues

Follow manufacturer clearance guidelines

Consider thermal expansion differences between shaft and bushing

Avoid grinding the bushing bore too tight

Use clean lubrication to reduce friction

Inspect shaft wear to avoid clearance changes over time

2). Recommended Clearance Ranges

(These vary by design, but general guidelines apply.)

| 애플리케이션 | Typical Clearance |

|---|---|

| Pumps | 0.05–0.12 mm |

| Compressors | 0.02–0.10 mm |

| High-temperature service | More clearance required |

결론

Misalignment and clearance problems may look similar, but their wear patterns are very different.

By understanding both failure modes and using proper measurement tools, companies can reduce breakdowns and extend WC bushing life.

Correct installation, accurate machining, and regular inspection are the keys to avoiding these issues.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.