In heavy industries, tools and machine components must survive extreme working conditions. They face constant wear, strong impacts, and high temperatures.

This is why 텅스텐 카바이드 마모 부품 are so popular. They offer a rare mix of 경도 그리고 강인함 — two properties that are often in conflict.

In this article, we will explain what hardness and toughness mean, how they differ, and why carbide wear parts stand out in modern manufacturing.

We will also cover examples, selection tips, and how industries balance these properties for maximum performance.

Understanding Hardness in Carbide Wear Parts

Hardness is the ability of a material to resist being scratched, dented, or worn down.

In simple words, the harder the material, the more it can cut, grind, or resist abrasion.

In tungsten carbide wear parts, 경도 comes from the tungsten carbide grains in the structure.

These grains are extremely strong, almost as hard as diamonds.

The Vickers hardness of tungsten carbide is around 1700–2400 HV, which is much higher than steel.

Why hardness matters:

High hardness means the surface resists scratches from sand, rocks, and other materials.

It improves the lifespan of cutting edges, drill tips, and wear plates.

It keeps the part’s shape even after months of heavy use.

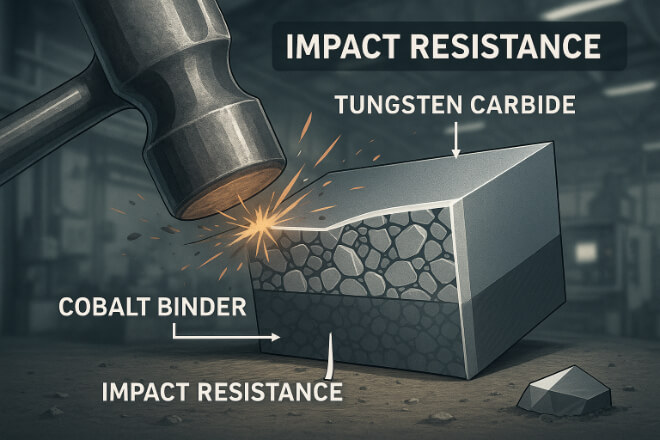

Understanding Toughness in Carbide Wear Parts

Toughness is the ability to resist breaking, cracking, or chipping when hit. A material can be very hard but still break easily if it is not tough.

In carbide wear parts, 강인함 comes from the metal binder, often cobalt (Co).

The binder holds the hard carbide grains together and absorbs impact.

Higher binder content increases toughness but can lower hardness.

Why toughness matters:

Prevents sudden breakage during high-impact work (mining, drilling, crushing).

Reduces risk of catastrophic failure in tools.

Important for parts in machines that face vibration or shock loads.

Hardness vs. Toughness — The Balancing Act

Hardness and toughness are like a seesaw. Increasing one often reduces the other.

높은 경도, low toughness → Best for constant abrasion, but can crack under heavy shock.

높은 강인함, lower hardness → Better for impact loads but may wear faster.

This is why manufacturers create different grades of carbide to suit specific working conditions.

Comparing Hardness and Toughness in Carbide Grades

| 카바이드 등급 | 경도(비커스 HV) | 강인함 | 최상의 사용 |

|---|---|---|---|

| 고운 입자, 낮은 바인더 | 2200–2400 | 낮은 | Precision cutting, wear plates |

| 중간 입자, 중간 바인더 | 1800–2000 | 중간 | General-purpose wear parts |

| 조립질, 고결합제 | 1400–1600 | 높은 | Mining tools, impact applications |

How Industries Choose the Right Balance

Different applications need different levels of hardness and toughness.

채광 and Quarrying: Needs high toughness to handle impact from rocks.

Metal Cutting Tools: Needs high hardness for long cutting life.

석유 및 가스 Drilling: Needs a balanced grade for both wear and impact resistance.

Agriculture Equipment: Medium grades to handle soil abrasion and shock.

Manufacturers test each grade for wear rate, fracture resistance, and heat stability before choosing the best option.

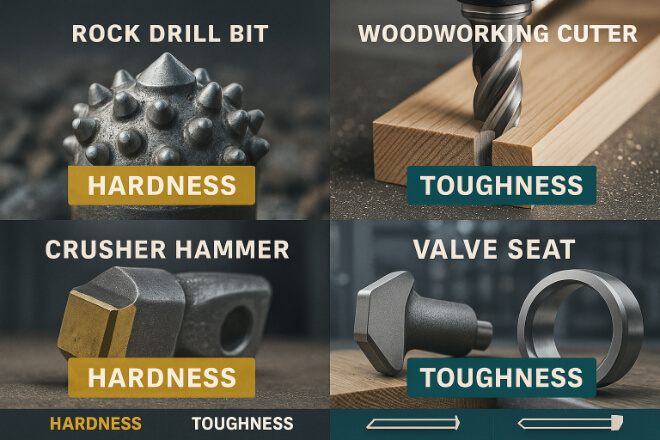

Real-World Examples of Hardness vs. Toughness in Carbide Wear Parts

Rock Drill Bits – Designed with more binder for 강인함 to prevent breakage in deep drilling.

Woodworking Cutters – Fine-grain, high-hardness grades to keep sharp edges longer.

파쇄기 Hammers – Balanced grade to survive both impact and abrasive wear.

Valve Seats in Oil Rigs – Corrosion-resistant carbide with enough hardness to last in high-pressure environments.

Why Carbide Is Unique Compared to Other Materials

Steel can be tough but not as hard. Ceramics can be hard but too brittle.

텅스텐 카바이드 마모 부품 combine both in a single material — thanks to powder metallurgy techniques that control grain size and binder content.

Key benefits:

Longer service life

Better performance in extreme environments

Reduced downtime and replacement costs

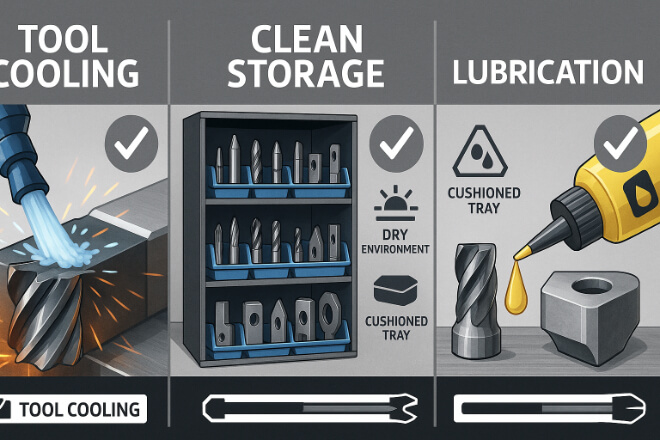

Tips for Maintaining Hardness and Toughness in Carbide Wear Parts

Avoid overheating during use; excessive heat can reduce binder strength.

Store tools in a dry, clean place to prevent corrosion of the binder.

Use the right coolant or lubrication in cutting operations.

Choose the correct grade for your specific application.

결론

The uniqueness of tungsten carbide wear parts lies in the delicate balance between hardness and toughness.

Understanding these properties helps decision-makers choose the right grade for their industry.

The right choice can mean the difference between frequent replacements and years of reliable performance.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.