When sourcing tungsten carbide bushings, the final price is not only determined by the material grade or size.

Two factors—MOQ (Minimum Order Quantity) and lead time—play a major role in shaping the total cost.

Understanding how these two elements influence pricing helps decision-makers control budgets, avoid delays, and build a more stable supply chain.

Why MOQ Matters in Bushing Pricing

MOQ is the smallest number of pieces a supplier is willing to produce or ship.

For tungsten carbide bushings, MOQ affects cost because carbide manufacturing involves powder preparation, pressing, sintering, machining, and finishing—each requiring setup time and fixed expenses.

1). Why Higher MOQ Lowers Cost

Lower machining cost per piece

More efficient use of raw materials

Reduced setup and tooling cost

Batch sintering improves production efficiency

Lower inspection cost per part

2). Why Low MOQ Raises Cost

Higher waste ratio

More time spent setting up machines

Difficulty reaching furnace capacity

Expensive unit inspection cost

3). MOQ vs. Cost Table

| MOQ Level | Typical Quantity | Cost Per Piece | 이유 |

|---|---|---|---|

| Low MOQ | 1–10 pcs | Highest | High setup cost, low efficiency |

| Medium MOQ | 50–200 pcs | 보통의 | Better machining and furnace use |

| High MOQ | 500+ pcs | Lowest | High efficiency and bulk savings |

OEMs with stable demand often benefit most from medium to high MOQ.

How Lead Time Influences Bushing Cost

Lead time reflects the total time from order confirmation to delivery.

In carbide manufacturing, lead time affects cost because suppliers adjust production schedules, raw material planning, and furnace load.

1). Short Lead Time → Higher Cost

When the customer needs bushings fast:

Supplier must rearrange production

Must buy material quickly at higher cost

Must pay overtime or night-shift labor

May need to run smaller furnace batches

Must do express shipping

2). Long Lead Time → Lower Cost

With more time:

Supplier can optimize furnace loading

Material can be ordered at normal price

No rush machining

Better batch inspection control

Lower logistics cost

3). Lead Time vs. Cost Table

| Lead Time | Typical Range | Cost Level | 노트 |

|---|---|---|---|

| Urgent | 1–2 weeks | Highest | Rush machining + express shipping |

| 기준 | 3–5 weeks | 중간 | Normal production flow |

| Extended | 6–10 weeks | Lowest | Batch optimization and furnace efficiency |

OEMs with predictable schedules benefit most from standard or extended lead times.

Why MOQ and Lead Time Are Connected

MOQ and lead time often work together to impact cost.

1). Small MOQ + Urgent Lead Time = Maximum Cost

This combination requires:

Machine changeover

Low furnace utilization

Extra inspection time

Fast logistics

2). Large MOQ + Long Lead Time = Minimum Cost

This creates:

High efficiency

Smooth workflow

Low unit production cost

3). Why These Two Factors Must Be Balanced

OEMs with new product lines may need low MOQ

OEMs with stable demand benefit from large batches

High-performance pumps may need long lead-time quality tests

Spare parts projects may need quick turnaround

OEMs should review project type before deciding MOQ and lead time.

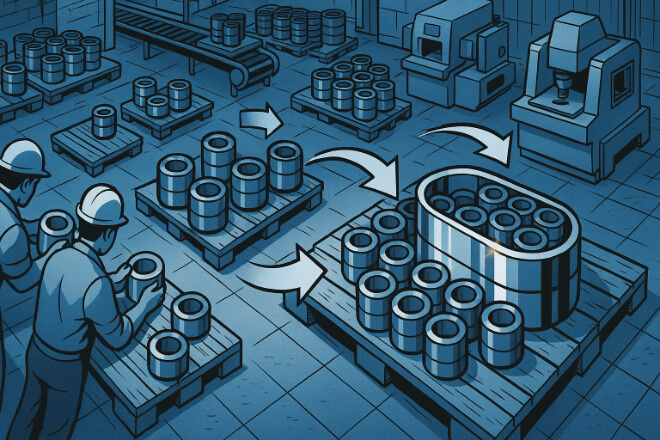

How OEMs Can Reduce Bushing Cost Through Better MOQ Planning

OEMs can reduce cost without reducing quality by planning MOQ strategically.

Strategy 1: Combine Orders by Model

Instead of ordering:

5pcs of Model A

6pcs of Model B

4pcs of Model C

OEMs can combine orders:

15pcs every quarter

This reduces setup time and cost.

Strategy 2: Forecast Demand Earlier

More accurate planning allows suppliers to:

Prepare powder earlier

Plan furnace cycles

Reduce rush production

Strategy 3: Keep a Small Safety Stock

If usage is predictable, OEMs may maintain a small stock to avoid urgent orders with high cost.

How OEMs Can Lower Cost Through Lead Time Management

Lead time optimization is often easier than MOQ optimization.

Strategy 1: Order Before Peak Season

Carbide manufacturers often have peak months.

Ordering early avoids rush fees.

Strategy 2: Align with Supplier Production Cycles

If a supplier runs furnace cycles every Monday and Thursday, ordering aligned with their cycle reduces waiting time.

Strategy 3: Approve Drawings Quickly

Delays in drawing approval often create accidental rush orders.

Strategy 4: Use Standard Inspection Instead of Special Tests

If not required, avoid:

100% ultrasonic test

Full-size CMM inspection

Extra hardness sampling

These special inspections increase lead time and cost.

What Decision-Makers Should Ask Suppliers

To optimize MOQ and lead time, OEMs should ask transparent questions.

Recommended Questions

What is the best MOQ for cost efficiency?

How does lead time change with different quantities?

Can the supplier offer batch price breaks?

What is the typical furnace cycle schedule?

Does the supplier stock common material grades?

Are there off-peak production periods with lower cost?

The answers guide OEMs toward the lowest overall cost.

결론

MOQ and lead time significantly influence the final cost of tungsten carbide bushings.

OEMs who plan ahead, forecast demand, and align their orders with supplier production cycles can achieve lower unit prices and more reliable delivery.

Smart sourcing decisions reduce total cost while maintaining the high quality required for pumps, compressors, and heavy machinery.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.