Good shaft alignment is one of the most important factors for achieving long service life in tungsten carbide bushings.

When the shaft is not aligned well, the bushing faces extra stress, heat, and wear. This leads to early failure and higher maintenance costs.

This article explains how to improve shaft alignment using simple steps, practical tools, and industry best practices.

Why Shaft Alignment Matters for Bushing Life

Shaft alignment refers to how well the shaft centerline matches the bushing centerline. Even small alignment errors can create big problems during operation.

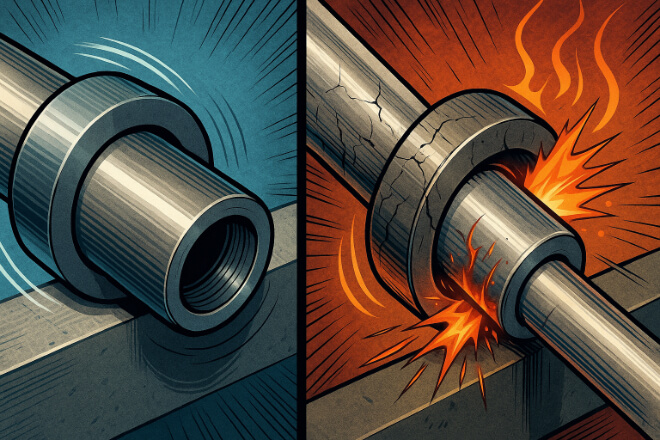

1). Key Issues Caused by Poor Alignment

Higher friction and heat

Uneven load on the bushing

Faster wear and shorter service life

Vibration and noise in the machine

Increased energy consumption

Damage to pump or motor bearings

2). How Good Alignment Helps

Lower friction and smooth rotation

Longer bushing lifespan

Lower maintenance frequency

Better pump or machine efficiency

가동 중지 시간 감소

Good alignment ensures the tungsten carbide bushing works under stable and balanced conditions, which is critical for long-term performance.

Common Causes of Misalignment

Many factors can cause misalignment. Understanding them helps decision-makers improve reliability.

1). Installation Errors

Improper installation is one of the most common causes. These include:

Uneven tightening of bolts

Incorrect press-fit

Poor mounting base

Using wrong tools or low precision jigs

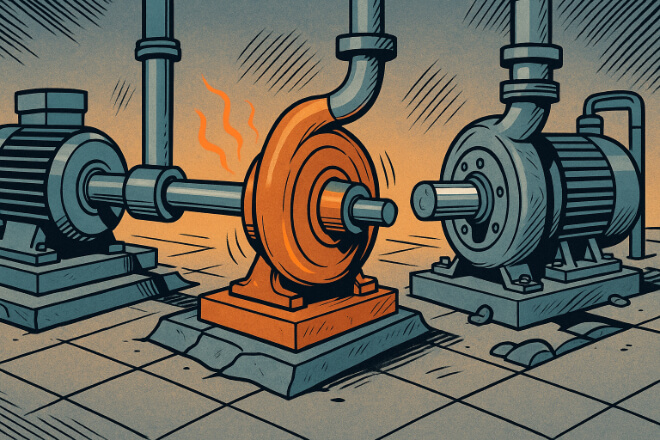

2 ).Thermal Expansion

When machines run at high speeds or under high loads, parts heat up. Different materials expand at different rates, creating shaft displacement.

3). Wear of Machine Parts

Over time, bearing housings, motor feet, baseplates, and shafts may wear or deform.

4). Vibration and External Forces

Unbalanced rotating parts, pressure surges, or unstable foundations can shift the shaft out of position.

5). Manufacturing Tolerances

If either the shaft or the housing is not made with proper accuracy, misalignment will appear even before installation.

Types of Shaft Misalignment

Understanding the types of misalignment helps choose the right correction technique.

| 유형 | 설명 |

|---|---|

| Angular Misalignment | The shaft is tilted relative to the bushing axis. |

| Parallel (Offset) Misalignment | The shaft centerline is shifted sideways. |

| Vertical Misalignment | The shaft sits too high or too low. |

| Horizontal Misalignment | The shaft is displaced left or right. |

Even a small variation in alignment can greatly reduce 텅스텐 카바이드 부싱 life because the material is hard but brittle, and uneven loads can create stress.

Tools and Methods to Improve Shaft Alignment

Different tools can be used depending on the accuracy needed and the budget available.

1). Straightedge and Feeler Gauge (Basic Method)

This is the simplest method. It is commonly used for small motors or general-purpose equipment.

1.1). Pros:

Low cost

Easy to use

1.2). Cons:

Low accuracy

Not suitable for high-precision pump systems

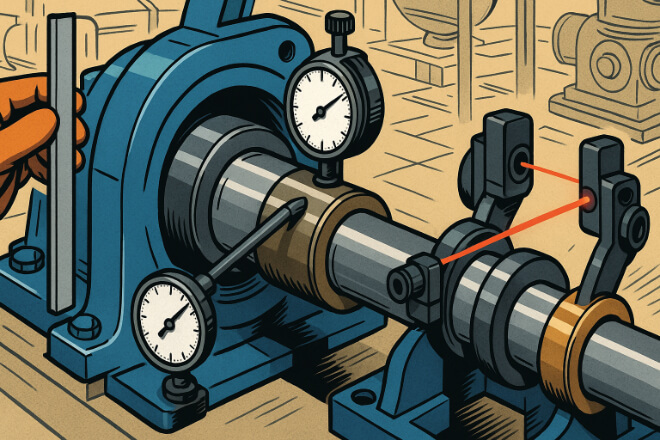

2). Dial Indicator Alignment

Dial indicators measure the relative movement between two shafts.

2.1). Pros:

More accurate than a straightedge

Easy to adjust based on readings

2.2). Cons:

Requires trained personnel

Time-consuming for large machines

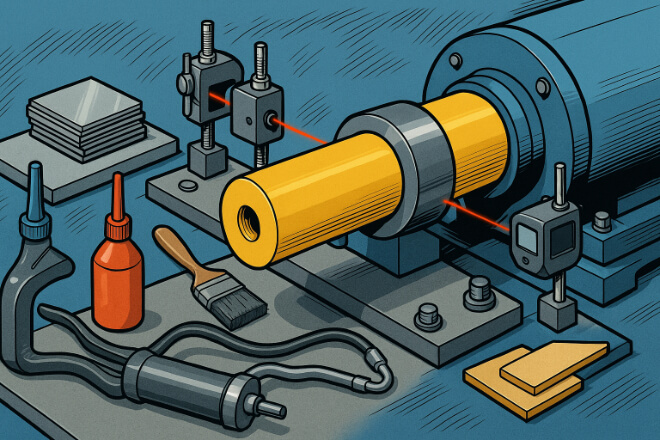

3). Laser Alignment Systems (Best for Industry)

Laser alignment is the most modern and precise method.

3.1). Pros:

Very high accuracy

Fast setup and measurement

Helps document alignment records

Reduces human error

3.2). Cons:

Higher cost

Requires trained operators

Steps to Improve Shaft Alignment

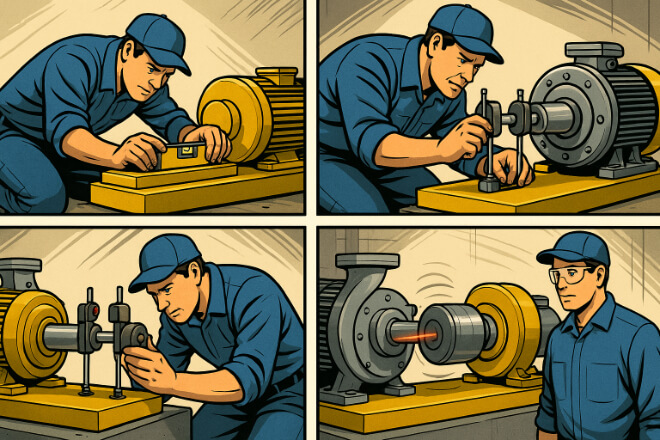

1) Prepare the Base and Mounting Surface

A stable foundation is the first step to good alignment.

Clean all mounting surfaces

Remove rust or dirt

Check for cracks or unevenness

Use shims for height correction

Make sure the baseplate is level

2) Align Before Tightening Bolts

During installation:

Position the machine loosely

Check alignment first

Tighten bolts slowly and evenly

Recheck alignment after tightening

3) Measure Thermal Growth

In high-temperature applications:

Calculate thermal expansion

Set “cold alignment” to compensate

제조업체 권장 사항을 따르세요

Use thermal growth offset charts

4) Use Laser Alignment for Final Adjustment

For pumps, compressors, and high-speed motors:

Use a laser alignment device

Set vertical and horizontal corrections

Verify offset and angular alignment

Record final readings

5) Verify Shaft and Bushing Clearance

Clearance affects alignment stability. If the clearance is too tight or too loose, misalignment becomes worse.

| Item | Typical Range |

|---|---|

| Bushing-to-Shaft Clearance | 0.02 – 0.10 mm |

| Radial Runout | ≤ 0.01 mm |

| Shaft Straightness | ≤ 0.02 mm |

6) Conduct a Trial Run

After alignment:

Run the machine at low speed

Check vibration levels

Check temperature rise

Listen for noise

Re-measure after 2–4 hours of operation

7) Recheck Periodically

Alignment does not last forever. Regular checks improve bushing life.

Recommended intervals:

Every 3–6 months for critical pumps

Once a year for standard equipment

Immediately after heavy vibration events

How Proper Alignment Extends Bushing Life

Proper shaft alignment gives tungsten carbide bushings three major benefits:

Reduced Friction and Heat: Well-aligned shafts rotate smoothly inside bushings. This reduces heat buildup, which slows wear.

More Even Load Distribution: Misalignment causes point-contact stress. Good alignment spreads the load across the whole bushing surface.

Less Vibration and Noise: Stable rotation protects not only the bushing but also seals, bearings, and pump shafts.

Longer Operating Life: With lower friction, lower stress, and better stability, tungsten carbide bushings can last 2–4 times longer in many applications.

Best Practices for Maintaining Alignment

Use High-Quality Shims: Shims improve vertical alignment. Choose stainless steel or corrosion-resistant materials.

Monitor Bearing Conditions: Damaged bearings can pull the shaft out of alignment. Replace them early.

Avoid Excessive Force During Installation: Do not hammer the bushing. Use a press with controlled force.

Maintain Proper Lubrication: Insufficient lubrication increases friction and pushes the shaft off-center.

Keep the System Clean: Dust, rust, or debris on the mounting area affects equipment position.

Checklist for Alignment Improvement

| Checklist Item | Status |

|---|---|

| Baseplate is clean and level | Yes/No |

| Bolt tightening sequence correct | Yes/No |

| Thermal growth compensation done | Yes/No |

| Laser alignment verified | Yes/No |

| Vibration levels normal | Yes/No |

| Bushing clearance within limit | Yes/No |

| Trial run completed | Yes/No |

결론

Improving shaft alignment is one of the most effective ways to extend the life of tungsten carbide bushings.

With proper installation, accurate measurement tools, and regular checks, companies can reduce wear, save maintenance costs, and improve machine reliability. Good alignment protects the bushing and the entire system.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.