Tungsten carbide is one of the hardest and most reliable industrial materials. It is widely used in 절단 도구, mining equipment, 마모 부품, and precision components.

But before companies can trust these parts in critical operations, they need to confirm the quality, 경도, 강인함, and performance of the carbide. That is where testing comes in.

For decision-makers, understanding how tungsten carbide is tested is essential. It helps you evaluate suppliers, reduce the risk of premature failures, and make better long-term purchasing decisions.

This article explains the most common methods for testing tungsten carbide, why each test matters, and what results to expect.

Why Testing Tungsten Carbide Matters

Tungsten carbide’s performance depends not only on its chemical composition but also on its grain size, binder content, density, and manufacturing process. Even small defects can lead to:

Cracks under stress.

Faster tool wear.

Poor dimensional accuracy.

Higher operational costs.

Testing ensures that the carbide parts meet industry standards and deliver the durability that companies expect.

Reliable testing also helps manufacturers guarantee consistency across batches.

Visual and Dimensional Inspection

The first step in testing carbide parts is often simple inspection. Skilled technicians or automated systems check for:

Surface defects like cracks, chips, or pores.

Dimensional accuracy, measured against CAD drawings or design specifications.

Finish quality, especially important in cutting tools.

Modern suppliers use CMM (coordinate measuring machines) and laser scanners to confirm precision.

While basic, these checks are critical for catching visible issues early.

경도 테스트

Tungsten carbide is known for its hardness. The most common test methods are:

Rockwell A (HRA) – Frequently used for tungsten carbide, giving values between 75–94 HRA.

Vickers Hardness Test – Uses a diamond indenter to measure hardness across a wide range.

Knoop Test – For very thin samples or coatings.

Hardness is important because it directly relates to 내마모성. A higher hardness means longer life in abrasive applications.

However, 경도 alone does not guarantee performance; toughness must also be tested.

Density and Porosity Testing

Tungsten carbide must have a high and uniform density to perform well. Low density or excessive porosity weakens the material and reduces tool life.

Manufacturers use methods such as:

Archimedes principle – Comparing the weight of the part in air and water.

Ultrasonic testing – Detecting internal voids.

X-ray imaging – Identifying hidden 다공성.

Parts with consistent density show better strength and reliability in tough applications.

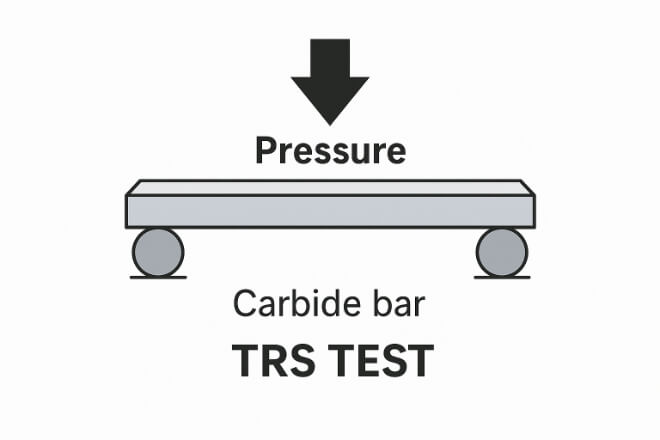

Transverse Rupture Strength (TRS) Testing

Also called flexural strength testing, TRS measures how much force tungsten carbide can withstand before breaking.

A rectangular carbide sample is placed on two supports.

Pressure is applied in the center until the part fractures.

The force at fracture indicates 강인함.

This test is important because it reveals the balance between 경도 and toughness, which is critical for industries like mining and oil & gas.

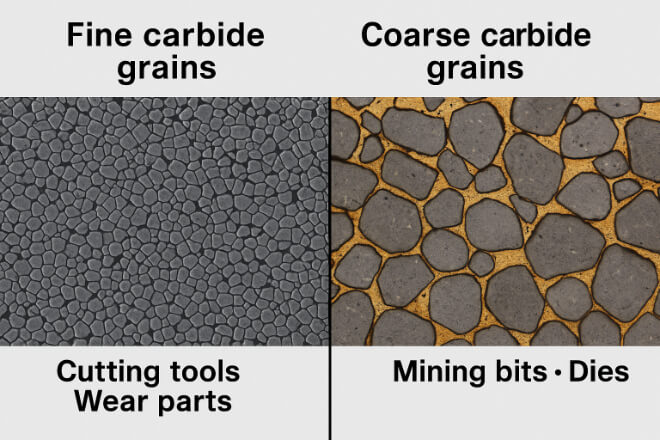

Grain Size Analysis

The performance of carbide depends heavily on grain size. Fine-grained carbides are ideal for precision cutting, while coarse grains are better for impact resistance.

Manufacturers typically use:

Microscopic examination to measure average grain size.

Image analysis software for statistical accuracy.

Grain size analysis helps ensure the carbide grade matches the application.

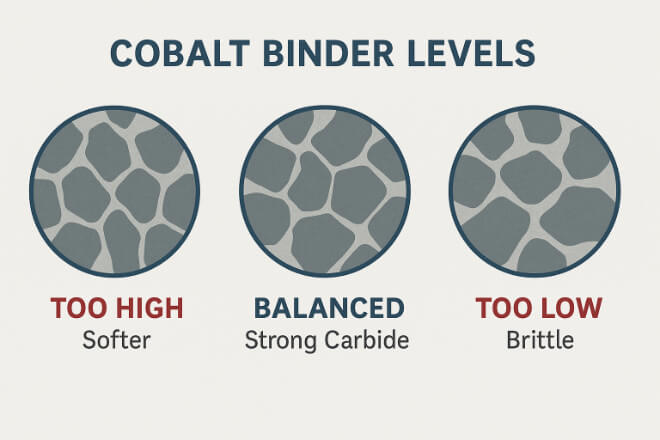

Binder Content Testing

Carbide parts are not pure tungsten carbide. They contain binders like cobalt or nickel that hold the grains together.

The binder percentage affects both hardness and toughness.

Too much binder = softer, tougher carbide.

Too little binder = harder but more brittle carbide.

Testing binder content ensures that the material has the correct composition for its intended use.

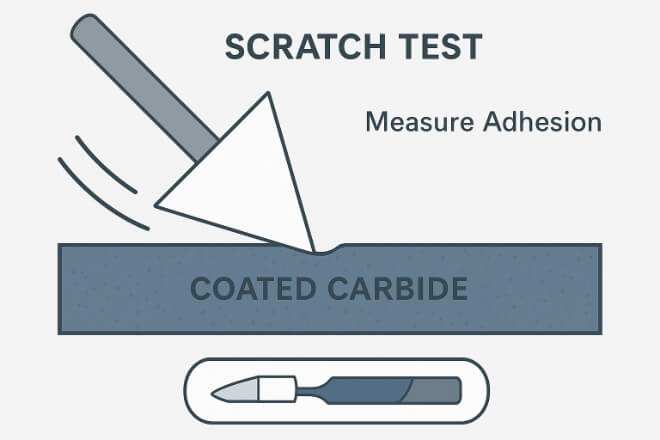

Coating Adhesion Testing

Many tungsten carbide parts are coated with PVD, CVD, or diamond layers to improve wear resistance. These coatings must be tested for adhesion.

Common tests include:

Scratch test – A diamond tip scratches the coating to measure bonding strength.

Impact test – Repeated stress applied to see if coatings crack.

Microscopy – Checking for peeling or uneven coating.

Strong coatings extend the life of carbide tools significantly.

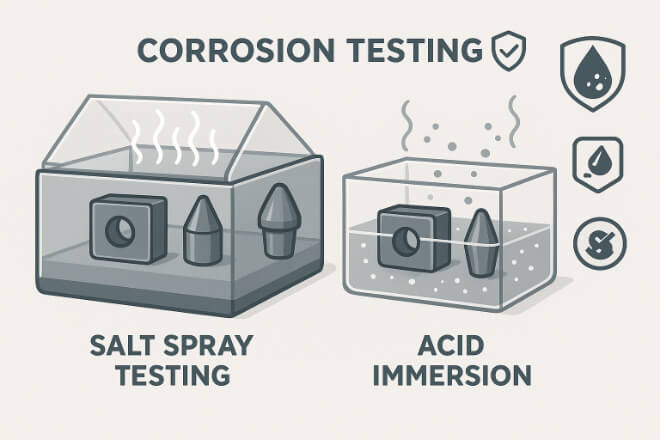

Corrosion and Chemical Resistance Testing

In industries like oil & gas or chemical processing, carbide wear parts are exposed to corrosive environments. Testing methods include:

Salt spray test – Simulates long-term exposure to corrosive conditions.

Acid/alkali immersion – Parts are dipped in solutions to measure resistance.

Electrochemical tests – Measure how easily a part corrodes under current flow.

These tests ensure that carbide parts will last in extreme environments.

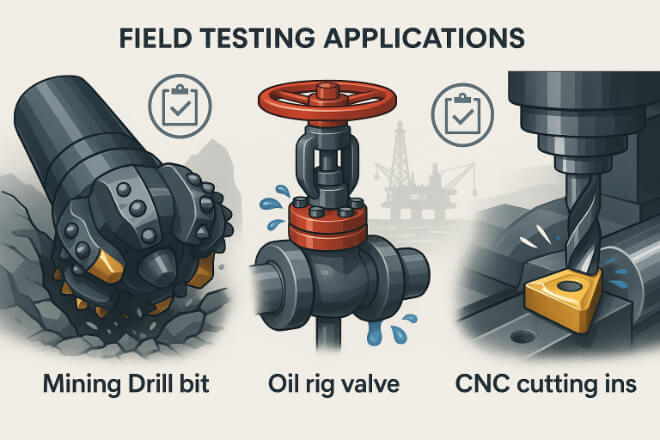

Real-World Performance Testing

Beyond laboratory testing, many manufacturers conduct field tests. These simulate the real conditions that carbide parts face, such as:

High-speed machining.

Mining with abrasive rock.

Oil drilling under extreme pressure.

Continuous cutting in paper and packaging industries.

Real-world performance testing validates lab results and builds customer confidence.

결론

Testing tungsten carbide is more than a technical process—it’s a business safeguard.

By choosing suppliers who follow strict testing protocols, decision-makers reduce risk, lower downtime, and get the best return on investment.

Whether through hardness, density, TRS, or coating adhesion tests, reliable evaluation ensures carbide parts meet the highest standards.

For industries that depend on efficiency, durability, and precision, testing is not optional—it’s essential.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.