Fertilizer and acid transfer pumps are essential components in industries such as agriculture and chemical manufacturing.

These pumps handle highly corrosive and abrasive substances like concentrated acids, fertilizers, and slurry, often under challenging conditions.

To ensure reliability and reduce downtime, many plants use tungsten carbide bushings in their pumps.

This article explores how tungsten carbide bushings improve the performance and lifespan of fertilizer and acid transfer pumps, offering benefits in both abrasive resistance and chemical stability.

Why Fertilizer and Acid Transfer Pumps Face Unique Challenges

Fertilizer and acid transfer pumps are exposed to a combination of high-flow, aggressive chemicals, and particulate matter.

These conditions make the pumps vulnerable to several types of wear and failure.

Key challenges faced by fertilizer and acid transfer pumps include:

Chemical corrosion from acids like sulfuric acid, nitric acid, and phosphoric acid

Abrasive wear from solid particles in slurry

High temperature in certain applications

Vibration caused by high-speed operation

Erosion from fast-moving liquids

Because of these tough operating conditions, traditional materials like bronze or stainless steel often fail quickly.

Tungsten carbide bushings, on the other hand, provide significant improvements in performance and durability.

How Tungsten Carbide Bushings Help Prevent Pump Failure

Tungsten carbide bushings are known for their remarkable 경도, 강인함, 및 내화학성.

These properties make them ideal for use in pumps handling abrasive and corrosive fluids.

Benefits of tungsten carbide bushings in fertilizer and acid transfer pumps:

Superior wear resistance against solid particles in slurry

특별한 내식성 to strong acids and fertilizers

High temperature stability, maintaining performance under heat

Longer service life, reducing the frequency of maintenance and replacement

Lower friction, resulting in better pump efficiency and reduced energy consumption

These characteristics ensure that pumps run smoothly for longer periods, even when handling the harshest media.

Understanding the Role of Tungsten Carbide in Corrosive and Abrasive Environments

Fertilizer and acid transfer pumps often handle aggressive media that can easily corrode and wear out unprotected parts.

Tungsten carbide is ideal for these conditions due to its combination of hardness and chemical stability.

Why Tungsten Carbide Performs Well:

경도:

Tungsten carbide is one of the hardest materials available, making it resistant to wear and abrasion from solids like sand, dirt, and fertilizers.

Tungsten carbide, especially grades with a nickel binder (WC-Ni), performs excellently in acidic environments, resisting attack from concentrated acids and fertilizers.

낮은 다공성:

The dense structure of tungsten carbide prevents fluid penetration, which helps to avoid internal corrosion or chemical attack.

High temperature tolerance:

Tungsten carbide maintains its properties at high temperatures, allowing pumps to operate under extreme heat without degradation.

By choosing tungsten carbide bushings, plants can dramatically improve the performance and longevity of pumps used in these aggressive applications.

Best Tungsten Carbide Grades for Fertilizer and Acid Transfer Pumps

Not all tungsten carbide grades are the same. Different binder types and grain sizes influence the material’s performance in various conditions.

For fertilizer and acid transfer pumps, the most common tungsten carbide grades are:

1). WC-Co (Cobalt Binder) Grades

가장 좋은 내마모성 in abrasive conditions

Suitable for fertilizers, slurry, and other solid-laden liquids

낮추다 내식성 compared to WC-Ni

2). WC-Ni (Nickel Binder) Grades

Superior corrosion resistance, particularly in acid and chemical environments

Ideal for handling concentrated acids and aggressive fertilizers

Less prone to binder leaching compared to WC-Co

3). Comparison Table: Tungsten Carbide Grades for Fertilizer and Acid Transfer Pumps

| 등급 | 접합재 | 장점 | Best Used In |

|---|---|---|---|

| WC-6Co | Cobalt | 높은 내마모성 | Fertilizer slurry, light acids |

| WC-12Co | Cobalt | Improved toughness | Fertilizer and abrasive media |

| WC-Ni | Nickel | 탁월한 내식성 | Acid transfer, strong chemicals |

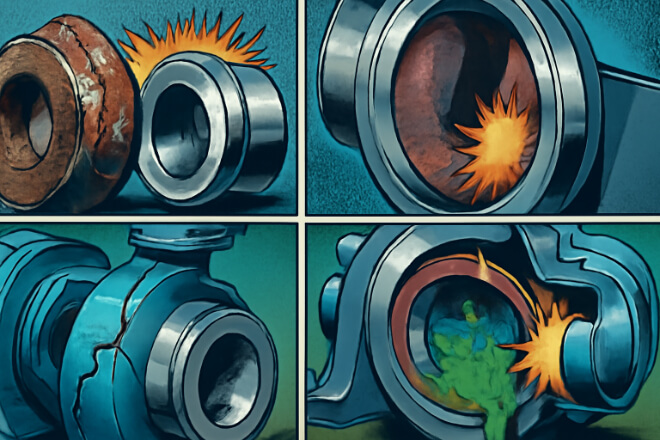

Common Failure Modes in Fertilizer and Acid Transfer Pumps

Even with robust materials like tungsten carbide, pumps can fail if the conditions become extreme or maintenance is neglected.

1). Typical failure modes:

Abrasive wear from solid particles in slurry

Chemical corrosion from concentrated acids and aggressive fertilizers

Binder leaching in cobalt grades when exposed to strong acids

Chipping or cracking due to misalignment or high pressure

Thermal stress cracking during rapid temperature changes

2). Failure Mode Summary Table

| Failure Mode | Cause | 해결책 |

|---|---|---|

| 연마 마모 | Fibers, sand, and particulate matter | Use WC-Co or WC-Ni grades |

| Chemical Corrosion | Exposure to strong acids | Switch to WC-Ni binder grade |

| Chipping or Cracking | Misalignment or excessive load | Ensure proper alignment and clearance |

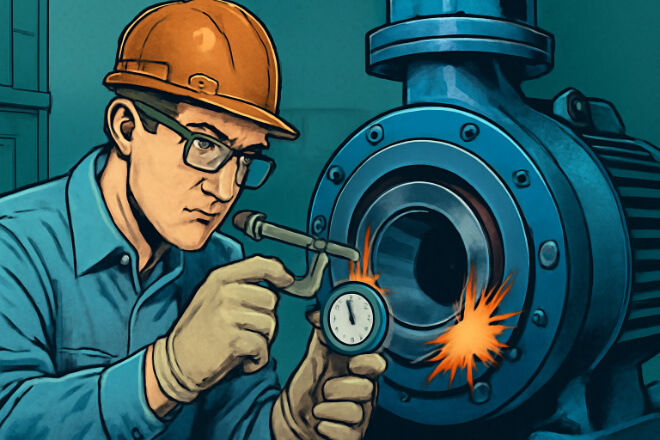

Maintenance and Inspection Tips

To maximize the lifespan of tungsten carbide bushings, regular maintenance and inspection are necessary.

Best practices for maintenance:

Inspect for wear or early signs of damage

Monitor alignment during scheduled shutdowns

Flush slurry pumps regularly to remove abrasive particles

Check lubrication levels to avoid dry running

Replace bushings before they reach critical wear

A proactive maintenance program ensures reliable pump performance and reduces downtime.

Choosing the Right Supplier for Fertilizer and Acid Transfer Pumps

Selecting the right supplier for tungsten carbide bushings is crucial to maintaining pump performance.

What to look for in a supplier:

Expertise in fertilizer and acid transfer applications

Ability to supply WC-Ni and WC-Co grades

Full testing and certification for 경도, 다공성, and microstructure

Quick lead times and stable supply chains

Support for custom bushing designs

A trusted supplier ensures you get high-quality, reliable bushings that reduce operational costs.

결론

Fertilizer and acid transfer pumps handle abrasive, corrosive fluids that place extreme stress on their components.

Tungsten carbide bushings provide the necessary hardness, corrosion resistance, and long life to keep these pumps running smoothly and efficiently.

By selecting the right grade, maintaining the system well, and partnering with a reputable supplier, companies can extend pump life and reduce costly downtime.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.