Rotating equipment—such as pumps, compressors, turbines, and marine systems—is the backbone of many industries, including 석유와 가스, chemical plants, marine operations, and power generation.

One of the biggest challenges in keeping this equipment running is seal failure. When seals fail, downtime increases, costs rise, and operations are put at risk.

This is why many companies choose 텅스텐 카바이드 씰 링. Known for their durability and reliability, these rings help extend the life of mechanical seals and reduce downtime.

This article explains how tungsten carbide seal rings achieve this, and why they are a smart choice for decision-makers.

Why Downtime Happens in Rotating Equipment

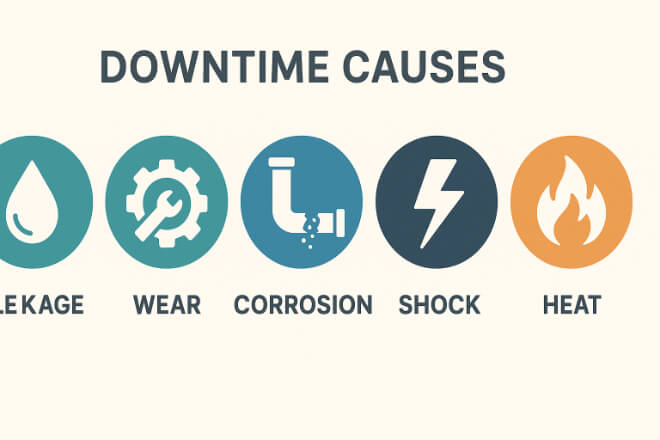

Downtime often results from seal problems such as:

Leakage → Allowing oil, gas, or water to escape.

마모 및 마모 → Caused by friction or particles in fluids.

Corrosion → From chemicals or seawater.

Mechanical shock → Pressure spikes or sudden vibration.

Thermal stress → Heat causing distortion or material breakdown.

When seals fail, the entire system must stop for repairs, which can cost thousands per hour in lost production.

텅스텐 카바이드 씰 링의 특성

Tungsten carbide is made from tungsten and carbon, bonded with either cobalt or nickel. Its unique properties include:

극심한 경도 → Reduces wear from friction and abrasive fluids.

높은 압축 강도 → Handles heavy loads without cracking.

열 안정성 → Maintains performance under high heat.

부식 저항성 → 바닷물, 기름, 화학물질에 강합니다.

치수 안정성 → Ensures a precise seal over long-term use.

These properties allow seals to survive longer in harsh environments, reducing downtime.

How Tungsten Carbide Seal Rings Reduce Downtime

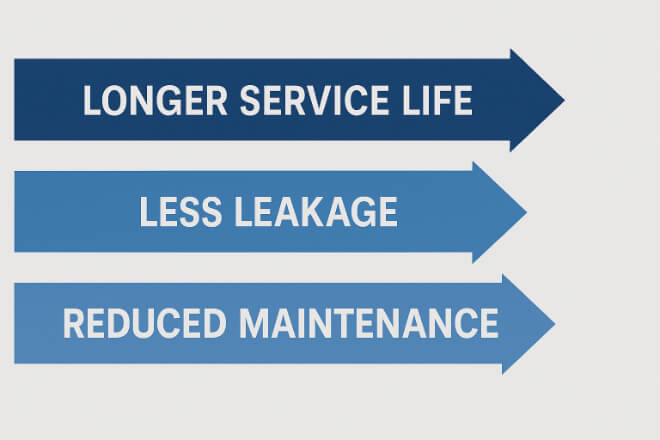

1). Longer Service Life

Because tungsten carbide resists wear and corrosion, seals last longer before needing replacement, lowering unplanned downtime.

2). Reliability in Harsh Conditions

Seals continue to perform even under high temperature, high pressure, and corrosive environments, ensuring equipment stays online.

3). Shock Resistance

Cobalt-bonded tungsten carbide handles vibration and pressure spikes better than ceramics, preventing sudden failures.

4). Reduced Leakage

Tungsten carbide maintains tight sealing, reducing leakage that would otherwise cause performance loss or shutdown.

5). Lower Maintenance Frequency

Less frequent inspections and replacements mean more time in operation, less time offline.

다른 씰 재료와의 비교

강철 씰 → Corrode quickly, short life span.

세라믹 씰 → Resist chemicals but brittle under impact.

실리콘 카바이드 씰 → Strong chemical resistance but less durable under shock.

텅스텐 카바이드 씰 → Balanced strength, durability, and resistance to wear and corrosion, making them the most reliable for uptime.

Applications in Rotating Equipment

텅스텐 카바이드 씰 링은 다음 분야에서 널리 사용됩니다.

석유 및 가스 compressors – Protect against wear in high-pressure drilling.

Power generation turbines – Maintain sealing under heat and stress.

Marine propulsion systems – Resist seawater corrosion and vibration.

Chemical plant pumps – Handle aggressive chemicals without early failure.

Wastewater systems – Prevent leakage in abrasive and corrosive fluids.

In each case, 텅스텐 카바이드 씰 링 reduce failures and increase operating hours.

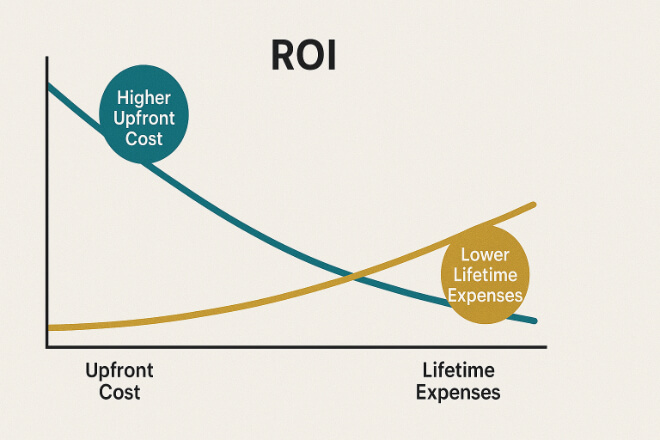

비용 대 장기적 가치

Tungsten carbide seal rings have a higher initial price, but the long-term benefits include:

Lower downtime costs.

교체 횟수 감소.

Extended equipment life.

Better overall ROI.

For decision-makers, this makes tungsten carbide a cost-effective investment.

텅스텐 카바이드 씰 링 사용 모범 사례

Match grade to environment → Cobalt for shock, nickel for corrosion.

Ensure proper installation → Prevent scratches that weaken seals.

Lubricate correctly → Reduce friction and heat buildup.

정기적으로 검사하세요 → Detect early wear and prevent sudden failure.

These practices maximize uptime and extend seal life.

Sustainability Advantage

Tungsten carbide is recyclable. Worn seal rings can be collected and reprocessed into new products, reducing waste and supporting sustainability goals.

의사결정자를 위한 주요 정보

Tungsten carbide seal rings significantly reduce downtime in rotating equipment.

Their durability, 강인함, and corrosion resistance outperform alternatives.

Right binder choice ensures reliability in different industries.

Higher upfront cost delivers long-term savings.

Recycling enhances sustainability.

결론

For rotating equipment in oil and gas, chemical, marine, and power industries, tungsten carbide seal rings are essential for reducing downtime.

Their ability to withstand harsh conditions ensures equipment runs longer, safer, and more efficiently.

For decision-makers, choosing tungsten carbide means fewer failures, lower costs, and stronger long-term value.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.