Cutting metal is one of the most demanding tasks for any cutting tool.

Whether it’s structural steel, aluminum, or other tough alloys, saw blades used for metal cutting must endure extreme forces, high temperatures, and abrasive wear.

Tungsten carbide tips are widely used in saw blades for metal cutting due to their exceptional 경도, 내마모성, and longevity.

In this blog, we will explore how tungsten carbide tips improve the performance of saw blades, increase cutting efficiency, and reduce operational costs in metal cutting applications.

1. What Is Tungsten Carbide and Why Is It Ideal for Metal Cutting?

Tungsten carbide is a metal composite made from tungsten and carbon, creating an incredibly hard and dense material.

This hardness makes it an ideal choice for cutting tough materials like metal, where high friction, heat, and pressure are common.

Why Tungsten Carbide is Ideal for Saw Blades:

경도: Tungsten carbide is one of the hardest materials available, allowing saw blades to maintain sharp cutting edges for extended periods.

내마모성: It resists abrasion and wear better than other materials, making it perfect for long cutting runs in metal.

내열성: Tungsten carbide remains stable at high temperatures, preventing tool failure during intense cutting operations.

These properties ensure that tungsten carbide-tipped saw blades can perform consistently and efficiently during metal cutting tasks.

2. How Tungsten Carbide Tips Improve Cutting Performance in Metal

Metal cutting often generates a significant amount of heat and friction.

Saw blades used in metal cutting need to maintain precision, cutting power, and durability under these challenging conditions.

Tungsten carbide tips are designed to handle these stresses better than regular steel or alloy tips.

Key Benefits of Tungsten Carbide in Metal Cutting:

Faster Cutting: Tungsten carbide tips allow for faster cutting speeds while maintaining tool performance.

Cleaner Cuts: The sharpness of carbide tips ensures precise, clean cuts, reducing burrs and the need for rework.

Reduced Heat Buildup: Tungsten carbide’s heat resistance helps dissipate the heat generated during cutting, reducing the risk of overheating the tool.

These characteristics allow tungsten carbide-tipped saw blades to outperform standard blades in metal cutting applications, making them ideal for heavy-duty tasks.

3. Types of Tungsten Carbide Tips Used in Saw Blades for Metal Cutting

Saw blades used for metal cutting are designed in various shapes and sizes, each suited for specific types of cuts and materials.

Tungsten carbide tips come in different configurations to provide optimal cutting performance.

Common Tungsten Carbide Tip Designs for Metal Cutting:

Flat-Tipped Carbide Blades: Commonly used for general metal cutting. These tips are ideal for cutting through mild to moderate metals.

Tipped with Alternating Teeth: These tips are designed for cutting harder metals. They are more durable and can handle both impact and heat.

Cemented Carbide Tips: Cemented carbide tips are made by bonding carbide particles with a metal binder, offering additional 강인함 and improved durability for tougher cuts.

Each type of carbide tip is chosen based on the specific metal and cutting requirements to maximize performance and tool life.

4. Advantages of Tungsten Carbide Tips in High-Speed Metal Cutting

High-speed cutting is common in industrial applications, and using the right materials in saw blades can make a significant difference in performance and cost-efficiency.

Tungsten carbide tips allow saw blades to operate at higher speeds without losing cutting efficiency.

How Tungsten Carbide Enhances High-Speed Cutting:

안정적인 커팅 엣지: Tungsten carbide tips maintain their sharpness even at high speeds, ensuring consistent cutting quality.

Increased Cutting Efficiency: Carbide-tipped blades can handle faster feed rates without sacrificing precision or cutting power.

Lower Maintenance Needs: Due to their 내마모성, carbide tips need less maintenance and last longer in high-speed operations.

These benefits make carbide-tipped saw blades ideal for high-volume metal cutting, where speed and precision are critical.

5. Wear Resistance: A Key Factor in Cost Savings

One of the main advantages of using tungsten carbide in saw blades is its exceptional wear resistance.

Metal cutting generates constant friction, which leads to rapid wear on tools.

Tungsten carbide helps minimize this wear, ensuring longer tool life and reducing the frequency of tool changes.

Wear Resistance and Cost Savings:

더 긴 공구 수명: Tungsten carbide blades last much longer than traditional steel blades, reducing the frequency of replacements.

Fewer Downtimes: With longer-lasting tools, machinery experiences less downtime, leading to increased productivity.

Improved Cutting Performance: As the carbide tips maintain their sharpness over time, cutting quality stays high, reducing the need for rework.

Overall, the 내마모성 of tungsten carbide tips makes them a cost-effective choice in metal cutting applications.

6. Improved Precision and Stability in Metal Cutting

In industries where precision is key, such as 항공우주 또는 자동차 manufacturing, tungsten carbide tips provide better cutting stability and accuracy than traditional tools.

How Tungsten Carbide Improves Cutting Precision:

Stable Cutting Action: Tungsten carbide tips help prevent wobbling or deviation during the cutting process, ensuring more accurate cuts.

Consistent Cutting Edge: 그 경도 of tungsten carbide allows the tool to maintain its cutting edge for a longer time, ensuring the cuts remain precise even after extended use.

Less Vibration: Tungsten carbide’s structural stability reduces the amount of vibration during cutting, which helps maintain high precision.

These qualities make tungsten carbide-tipped saw blades ideal for tasks that require high accuracy and stable cutting.

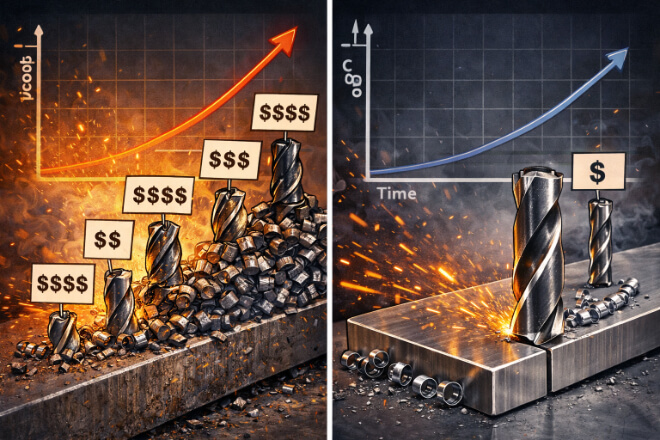

7. Cost Benefits of Tungsten Carbide Tips for Metal Cutting

Though tungsten carbide tips are more expensive than standard steel tips, they offer significant long-term cost savings.

These cost savings come from their increased durability, performance, and reduced maintenance needs.

Key Cost Benefits of Tungsten Carbide:

Fewer Tool Changes: Tungsten carbide tips last much longer than standard steel tips, reducing the need for frequent tool replacements.

Increased Efficiency: Faster cutting speeds and reduced downtime result in greater efficiency and higher productivity.

낮은 유지 관리 비용: Tungsten carbide’s durability means fewer repairs and less maintenance, lowering overall operational costs.

For decision-makers, investing in tungsten carbide tips results in lower total cost of ownership over time, especially in high-demand, high-precision metal cutting operations.

8. Applications of Tungsten Carbide Tips in Other Metal Cutting Tools

Tungsten carbide tips are used in a wide variety of other metal cutting tools, including:

Circular Saws: Tungsten carbide-tipped circular saw blades are commonly used for cutting metal sheets, pipes, and other thick metal materials.

Bandsaws: Tungsten carbide tips are used in bandsaw blades for precision metal cutting, especially in industries that require high cutting speed and accuracy.

Cutting Tools for CNC Machines: Carbide tips are used in CNC routers and lathes for cutting and shaping metal with great precision.

These tools benefit from the durability and performance of tungsten carbide, helping manufacturers cut metal more efficiently and accurately.

결론

Tungsten carbide tips play a crucial role in improving cutting performance in metal cutting operations.

Their hardness, wear resistance, and heat stability allow them to handle high-speed cutting and tough materials with ease.

Whether used in masonry saw blades, core drills, or other metal cutting tools, tungsten carbide tips help increase productivity, reduce downtime, and lower operating costs.

For decision-makers, investing in tungsten carbide-tipped tools is a cost-effective solution that ensures better performance, longevity, and cost savings over time.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.