Machining hard or difficult materials is a common challenge in modern manufacturing.

Whether cutting metal, wood, or plastic, tools must handle high stress, friction, and heat while keeping accuracy and speed.

Tungsten carbide tips are widely used because they offer strong cutting performance across many materials.

This article explains how tungsten carbide tips improve cutting performance in hard material machining and why they are effective for metal, wood, and plastic cutting applications.

1. Challenges of Hard Material Machining

Hard material machining puts heavy demands on cutting tools. Materials like hardened metals, dense wood, and reinforced plastics can quickly wear out standard tools.

Common challenges include:

Fast tool wear

높은 절삭력

Heat buildup

표면 마감이 좋지 않음

잦은 도구 교체

When tools fail early, production slows down and costs rise. Tungsten carbide tips are designed to handle these challenges by providing high 경도, stability, and 내마모성.

2. Why Tungsten Carbide Tips Are Suitable for Hard Materials

Tungsten carbide is a material made from tungsten and carbon, creating a very hard and dense structure. This makes it ideal for cutting hard or abrasive materials.

주요 속성은 다음과 같습니다.

매우 높음 경도

Good heat stability

Long edge life

These properties allow tungsten carbide tips to cut harder materials without losing their shape or sharpness.

As a result, cutting performance stays stable even under heavy loads.

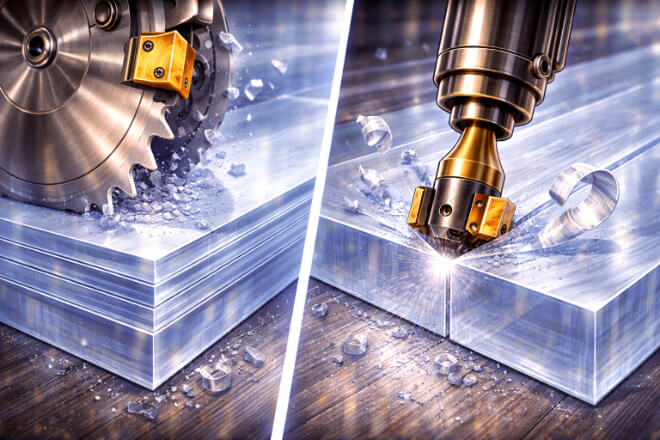

3. Improved Cutting Performance in Metal Machining

Metal machining often involves high temperatures and strong cutting forces.

Materials like steel, stainless steel, and alloys are difficult to cut with standard tools.

Tungsten carbide tips improve metal cutting by:

Keeping sharp edges at high temperatures

Reducing tool deformation

Allowing higher cutting speeds

Producing consistent chip flow

Because carbide tips resist heat and wear, they can run faster and longer.

This leads to better productivity and lower tool replacement rates in metal machining operations.

4. Benefits of Tungsten Carbide Tips in Wood Cutting

Wood may seem softer than metal, but dense hardwoods, engineered boards, and laminated materials can be very abrasive.

In wood cutting, tungsten carbide tips offer:

Strong resistance to abrasive fibers

Longer cutting edge life

Cleaner cuts with less tearing

Reduced need for re-sharpening

Carbide-tipped saw blades and cutters are widely used in woodworking because they maintain cutting quality over long production runs, even when cutting hard or treated wood.

5. Cutting Performance in Plastic and Composite Materials

Plastic and composite materials can cause unique cutting problems. Some plastics soften with heat, while composites contain abrasive fillers.

Tungsten carbide tips improve plastic cutting by:

Reducing friction and heat buildup

Maintaining smooth cutting edges

Preventing material sticking to the tool

Handling reinforced plastics with ease

For industries cutting plastic sheets, pipes, or composite panels, carbide tips help maintain stable cutting performance and surface quality.

6. Wear Resistance and Tool Life Improvement

Tool wear is one of the main limits to cutting performance. When edges wear quickly, cutting quality drops.

Tungsten carbide tips slow down wear because:

그들의 경도 resists abrasion

The cutting edge stays sharp longer

Heat-related wear is reduced

Longer tool life means:

도구 교체 횟수 감소

Less machine downtime

More stable production planning

This makes carbide tips especially valuable in high-volume machining.

7. Stability and Accuracy During Cutting

Stable cutting is important for both quality and safety. Tool vibration or edge failure can cause defects or damage.

Tungsten carbide tips improve stability by:

Maintaining edge shape under load

Reducing vibration during cutting

Providing consistent cutting forces

This stability helps achieve better dimensional accuracy and surface finish across metal, wood, and plastic cutting operations.

8. Comparison of Cutting Performance by Material Type

The table below shows how tungsten carbide tips perform compared to standard tool materials when cutting different materials.

| 재료 유형 | Standard Tool Performance | Tungsten Carbide Tip Performance |

|---|---|---|

| Metal | Fast wear, limited speed | High speed, long tool life |

| Hardwood | Edge dulls quickly | Clean cuts, extended sharpness |

| 플라스틱 | Heat buildup, sticking | Smooth cuts, low friction |

| 복합재료 | Rapid abrasive wear | 강한 내마모성 |

This comparison shows why tungsten carbide tips are preferred for machining a wide range of materials.

9. Cost Efficiency Across Multiple Materials

Using one tool type across different materials can simplify operations and reduce costs.

Tungsten carbide tips help lower total cost by:

Reducing tool inventory

Extending tool replacement cycles

Improving machine utilization

Increasing output per shift

Although carbide tools cost more at the start, they deliver better value over time when machining metal, wood, and plastic.

결론

Tungsten carbide tips significantly improve cutting performance in hard material machining. Their hardness, wear resistance, and heat stability allow them to cut metal, wood, and plastic efficiently and reliably.

By improving tool life, cutting stability, and productivity, tungsten carbide tips help decision-makers reduce costs and maintain consistent quality across different machining applications.

For manufacturers working with mixed materials, carbide-tipped tools are a proven and practical solution.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.