In many industrial machines, small components decide the reliability of the whole system.

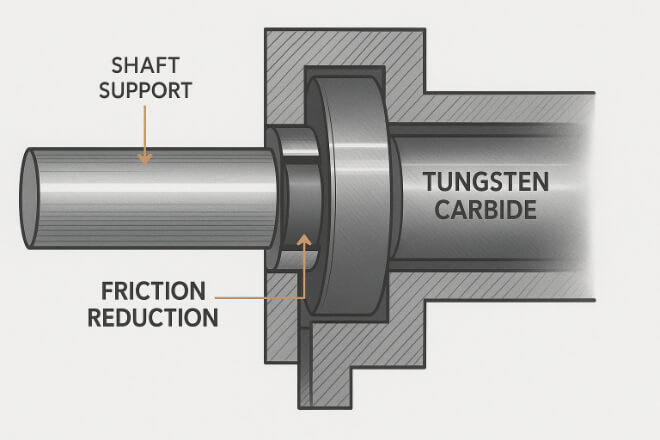

Bushings, also known as bearing sleeves, play a quiet but essential role — they reduce friction and protect shafts from wear.

When equipment runs under high load, abrasive media, or corrosive fluids, ordinary steel or bronze bushings cannot last long. This is where tungsten carbide bushings stand out.

These components are designed for maximum 내마모성 and long service life, even in the harshest operating environments.

This article explains the key material properties that make tungsten carbide bushings so durable and why they are the preferred choice for industries that demand precision, uptime, and cost efficiency.

Understanding Tungsten Carbide Bushings

에이 텅스텐 카바이드 부싱 is a mechanical part used to guide or support a rotating shaft and absorb wear and vibration.

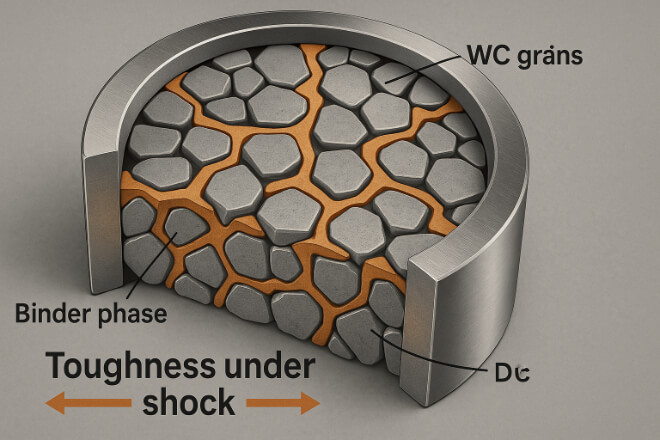

It is made by combining tungsten carbide (WC) powder with a metallic binder (usually cobalt or nickel) through sintering.

The result is a material that combines metal-like 강인함 with ceramic-like 경도 — perfect for applications that involve friction, pressure, and heat.

These bushings are used in:

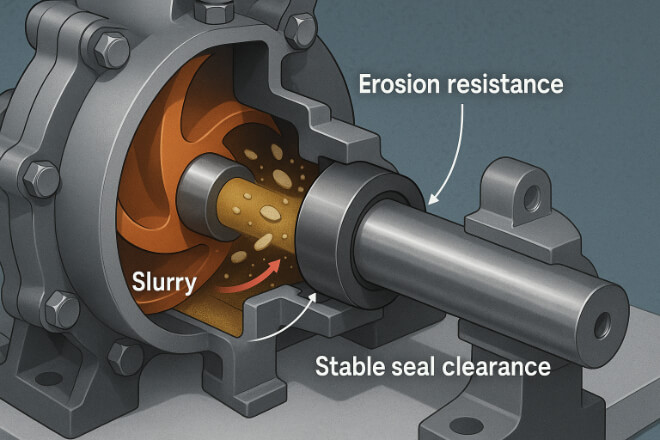

Pumps (shaft sleeves and wear rings)

Compressors (rotating and stationary bearings)

Submersible motors and slurry pumps

Valves and chemical equipment

Extreme Hardness for Wear Resistance

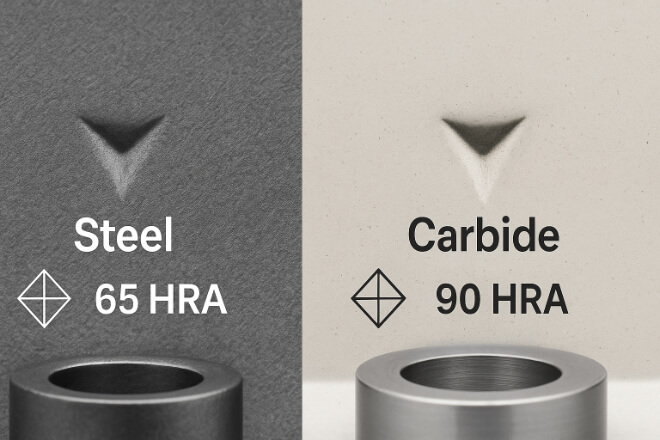

The most famous property of tungsten carbide is its 경도 — typically around 88–92 HRA (comparable to 1600–2000 HV on the Vickers scale).

This hardness allows the bushing to resist:

Abrasive wear from sand or particles

Deformation under high load

Scoring or galling caused by shaft contact

Because of this, tungsten carbide bushings last 5–10 times longer than hardened steel bushings in abrasive media like slurry or mud water.

High Compressive Strength

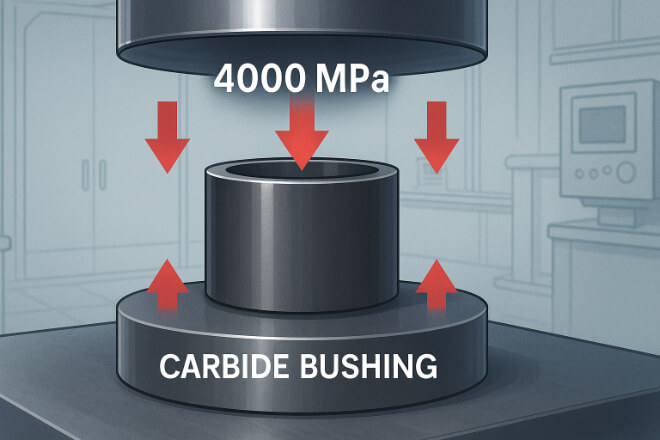

Tungsten carbide can withstand enormous pressure without deformation.

Its compressive strength is usually above 4000 MPa, meaning it can bear heavy loads without cracking or changing shape.

This is critical in high-pressure pumps and compressors, where even small deflections can cause shaft misalignment or leakage.

우수한 내식성

Unlike carbon steel or bronze, tungsten carbide is chemically stable. It resists attack from:

Water and seawater

Mild acids and bases

Hydrocarbon and chemical process fluids

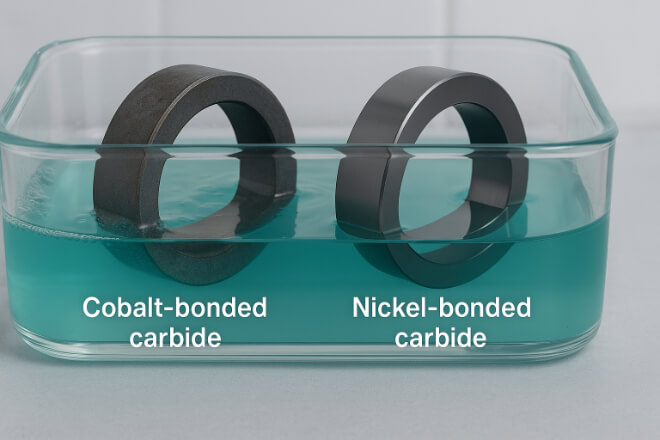

1). Binder Type and Corrosion Performance

| 바인더 유형 | Typical Environment | 부식 저항성 |

|---|---|---|

| 코발트(Co) | Oilfield, slurry, wear-intensive | Good, may oxidize in acids |

| 니켈(Ni) | Chemical, seawater, corrosive fluids | Excellent, resistant to acids |

For pumps used in chemical processing or seawater environments, nickel-bonded tungsten carbide is the preferred grade due to its superior corrosion performance.

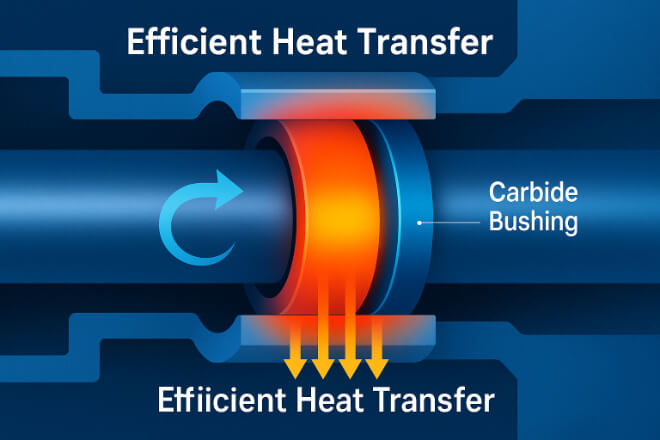

High Thermal Conductivity

Heat buildup can quickly destroy bushings made from softer materials. Tungsten carbide has high thermal conductivity (80–100 W/m·K), which helps to:

Transfer heat away from the contact zone

Prevent localized overheating

Maintain lubrication film stability

This is why tungsten carbide bushings remain dimensionally stable even in high-speed or high-temperature applications, such as turbine pumps and oilfield compressors.

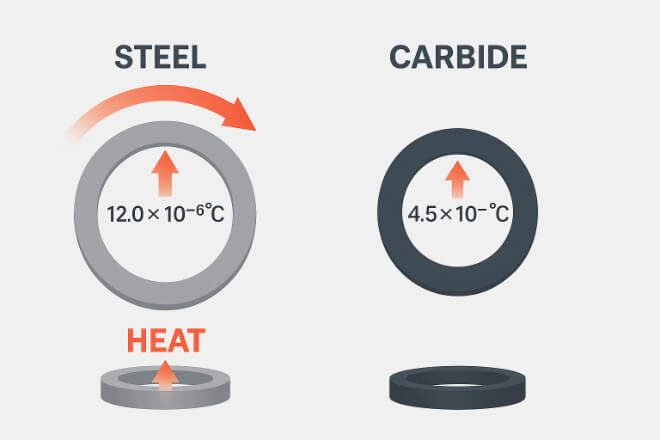

Dimensional Stability and Low Thermal Expansion

In high-precision rotating systems, even a small expansion can cause a loss of alignment or clearance.

Tungsten carbide has a very low coefficient of thermal expansion (CTE) — roughly 4.5 × 10⁻⁶/K, compared to 12 × 10⁻⁶/K for steel.

This means that as temperature changes, carbide bushings retain their shape and tolerances better, providing consistent operation and reduced vibration.

Chemical Inertness and Clean Operation

In industries like semiconductors or pharmaceuticals, contamination control is critical. Tungsten carbide’s chemically inert surface ensures that:

No metal ions leach into fluids

No oxidation or surface corrosion occurs

The surface remains smooth and clean for long periods

This property also makes carbide bushings suitable for deionized water, ultrapure chemicals, and vacuum systems.

Impact Resistance and Toughness

While tungsten carbide is hard, it’s also tough — especially when sintered with the right binder ratio.

A fine-grain microstructure allows the bushing to absorb small impacts without cracking.

This 강인함 is essential during start-up conditions, where dry contact or shaft vibration may occur before lubrication builds up.

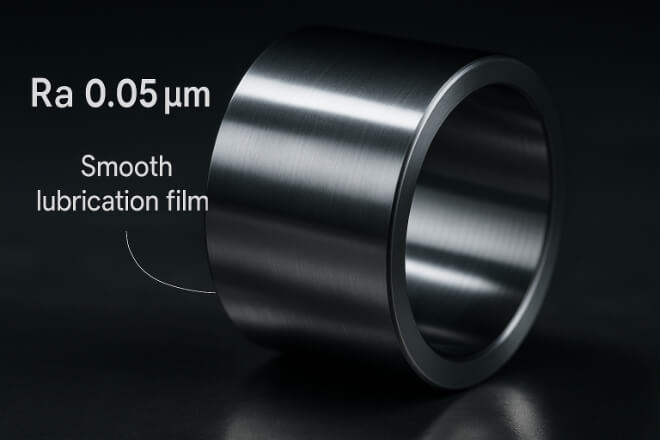

Surface Finish and Lubrication Compatibility

Tungsten carbide bushings can be finished to a mirror-level surface (Ra ≤ 0.05 µm), which minimizes friction and ensures stable lubrication film formation.

This is why these bushings operate smoothly in oil-lubricated, water-lubricated, or even dry gas-lubricated systems.

1). Typical Surface Requirements

| 애플리케이션 | 표면 거칠기(Ra) | 평탄 |

|---|---|---|

| Oil-lubricated pumps | ≤ 0.1 µm | ≤ 0.5 µm |

| Water-lubricated systems | ≤ 0.05 µm | ≤ 0.3 µm |

| Gas-lubricated or dry systems | ≤ 0.02 µm | ≤ 0.2 µm |

A smoother surface not only reduces wear but also prevents the formation of hotspots that could lead to premature failure.

Resistance to Abrasive Slurries and Particles

In environments like slurry pumps or mining pipelines, abrasive particles constantly hit the bushing surface.

Tungsten carbide’s combination of 경도 그리고 밀도 allows it to deflect or resist these impacts without eroding quickly.

When used in tandem with silicon carbide or hardened shafts, the result is a long-lasting, low-maintenance mechanical system.

Longevity and Cost Efficiency

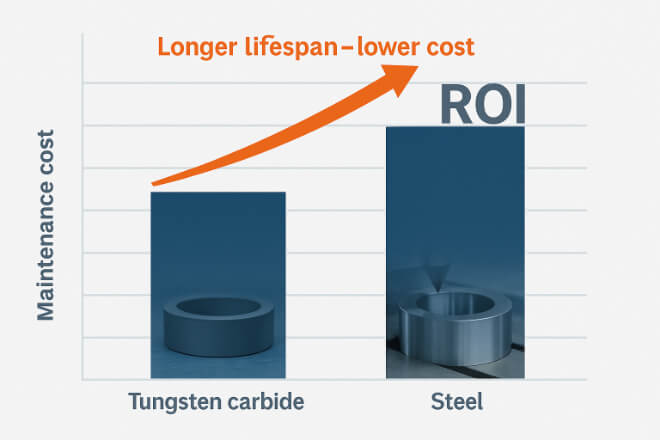

While tungsten carbide bushings cost more than traditional materials, their durability translates into major long-term savings:

Reduced downtime: Fewer replacements and less maintenance.

Stable performance: Consistent clearances and alignment.

Lower operating costs: Improved energy efficiency through reduced friction.

For high-wear applications, the total lifecycle cost of carbide bushings is often 30–50% lower than softer alternatives.

결론

The durability of tungsten carbide bushings comes from a powerful combination of 경도, strength, 내식성, and precision surface quality.

For industrial decision-makers, understanding these properties helps guide the selection of materials that deliver real, measurable returns — in uptime, reliability, and total cost savings.

Whether used in pumps, compressors, turbines, or chemical systems, carbide bushings remain one of the most trusted solutions for performance under pressure.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.