In pumps, compressors, turbines, and mixers, seal rings are small but essential parts.

They prevent leaks, protect systems, and reduce downtime. Choosing the right seal ring material is not only an engineering decision but also a business one.

Among many options, 텅스텐 카바이드 씰 링 are trusted worldwide. But there are two main types: nickel-bonded and cobalt-bonded. Both have unique properties, and the right choice depends on the application.

This article compares the two, explaining their strengths, differences, and best uses, helping decision-makers select the right solution for long-term performance.

텅스텐 카바이드 씰 링이란?

Tungsten carbide is made by combining tungsten and carbon powder, pressed together with a binder. The binder gives toughness and flexibility.

These rings are used in demanding industries where reliability and safety are critical.

응용 프로그램은 다음과 같습니다.

석유 및 가스 pumps and compressors

Chemical plants and refineries

Power generation systems

Marine and offshore pumps

Food and pharmaceutical equipment

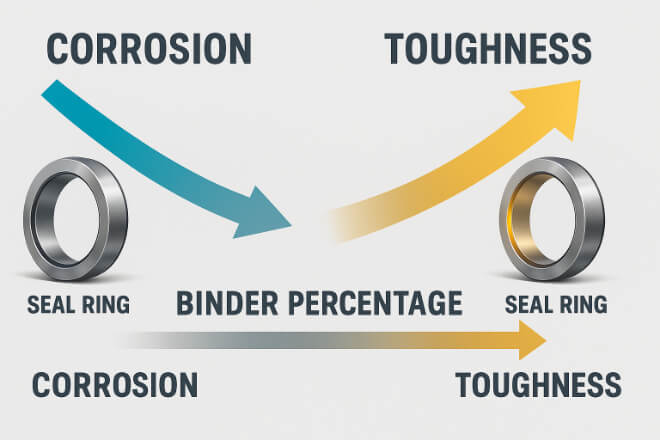

The Role of the Binder

The binder is not just filler. It changes the performance of the ring.

Cobalt: Improves 강인함, making the ring resist cracking under pressure.

Nickel: Improves 내식성, making the ring safer in acids and seawater.

Without the right binder, the seal ring may fail too soon, costing money and time.

Nickel-Bonded Tungsten Carbide Seal Rings

1). Key Properties

Strong resistance to acids, seawater, and chemicals

Stable performance in marine and chemical environments

약간 낮음 강인함 compared with cobalt-bonded types

2). Benefits

Best choice for corrosion-heavy environments

Reduces risk of leaks in chemical and marine systems

Longer service life in pumps exposed to corrosive media

3). Limitations

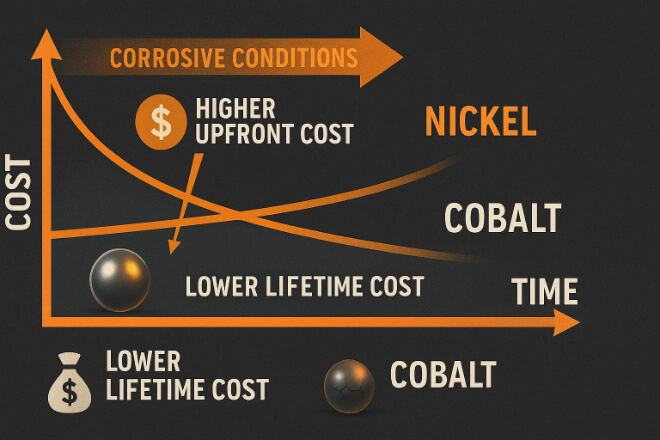

Higher cost than cobalt-bonded rings

Not as tough for heavy shock loads

Cobalt-Bonded Tungsten Carbide Seal Rings

1). Key Properties

훌륭한 강인함 and strength under load

Reliable in 석유, 가스, and mining industries

Less corrosion resistance compared to nickel-bonded

2). Benefits

Handles pressure and impact better

Lower cost compared with nickel-bonded rings

Performs well in abrasive and high-load systems

3). Limitations

Weaker against acids and seawater

May require more frequent replacement in corrosive applications

Side-by-Side Comparison

| 특징 | Nickel-Bonded Rings | Cobalt-Bonded Rings |

|---|---|---|

| 부식 저항성 | Excellent (acid, seawater, chemicals) | Moderate (weaker against acids) |

| 강인함 | Good, lower than cobalt | 매우 높음 |

| 내마모성 | 강한 | 강한 |

| Best Industry | Chemical, marine, pharmaceuticals | Oil, gas, mining, power plants |

| 비용 | Higher upfront cost | Lower upfront cost |

Industry Applications

1). 석유 및 가스 산업

Cobalt-bonded rings are common in drilling pumps and compressors because they handle pressure and shock.

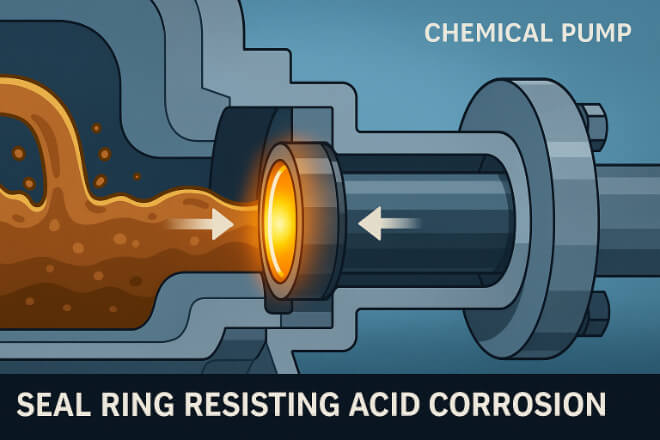

2). Chemical Processing

Nickel-bonded rings resist acids and solvents, making them safer and more cost-effective.

3) 해양 및 연안

Nickel-bonded rings last longer in seawater systems compared to cobalt-bonded.

4) 발전

Cobalt-bonded rings perform well in turbines where high load strength is more important than corrosion.

How to Select the Right Bonded Seal Ring

Decision-makers should evaluate:

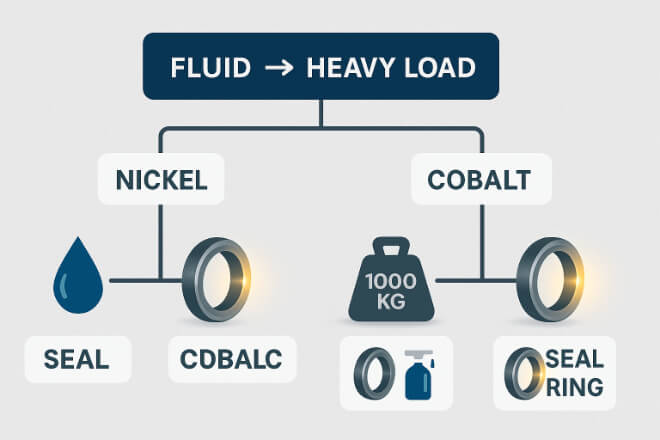

Fluid Type – Acidic or seawater? Choose nickel. Heavy load and impact? Choose cobalt.

Operating Conditions – High pressure vs high corrosion.

Budget – Nickel-bonded costs more but lasts longer in corrosive environments.

Industry Needs – Follow best practices in your field.

비용 및 ROI 고려 사항

Nickel-bonded: Higher initial cost but lower replacement frequency in corrosive systems.

Cobalt-bonded: Lower cost upfront but shorter life in chemical-heavy environments.

For decision-makers, the goal is to balance initial budget with lifetime value.

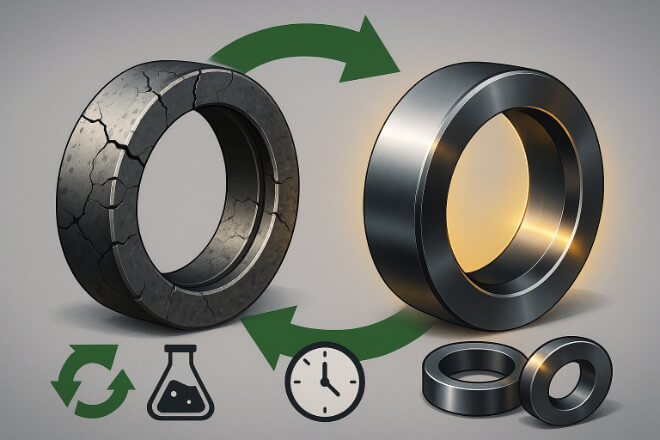

Maintenance and Replacement

Both nickel- and cobalt-bonded tungsten carbide rings need care:

Inspect regularly for cracks, wear, or corrosion marks

Replace on time before leaks or failures occur

Recycling option: worn tungsten carbide rings can be recycled, lowering cost

Case Examples

1). Marine Pump Manufacturer

Switched to nickel-bonded rings for seawater pumps. Result: longer seal life and reduced warranty claims.

2) 유전 압축기

Used cobalt-bonded rings to handle shock and high pressure. Result: stronger performance in drilling operations.

3) 화학공장

Nickel-bonded rings replaced stainless steel seals. Result: 50% longer service life and improved safety.

Business Value for Decision-Makers

For company leaders, the binder choice affects:

Machine uptime

Maintenance cost

Safety standards

Long-term ROI

니켈 결합 → best where corrosion is the biggest risk.

코발트 결합 → best where load and toughness are most important.

How to Source Tungsten Carbide Seal Rings

When buying, companies should:

Confirm binder type (nickel or cobalt) with supplier

Check ISO certifications for quality

Ask for case references in your industry

Choose suppliers with local stock for fast delivery

결론

Both nickel-bonded and cobalt-bonded tungsten carbide seal rings deliver excellent performance, but they serve different needs.

니켈 결합 → 내식성이 더 좋다

코발트 결합 → better for toughness and heavy loads

For decision-makers, the key is understanding the environment and matching the right binder type to the system.

This ensures safety, reduces downtime, and improves long-term savings.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.