올바른 것을 선택하다 carbide seal rings for aggressive chemical applications is not only about material 경도 또는 내마모성.

It is about matching the seal material to the process conditions — including media composition, pH value, and temperature range.

화학 처리와 같은 산업에서는 석유 및 가스, or pharmaceuticals, seal failure can mean production downtime, safety risks, and high replacement costs.

For decision-makers, specifying the right carbide material at the start can save both money and maintenance effort in the long term.

This article will guide you through how to specify carbide seal rings based on media type, pH, and temperature, with a practical mapping chart for quick reference.

Understanding the Role of Carbide Seal Rings

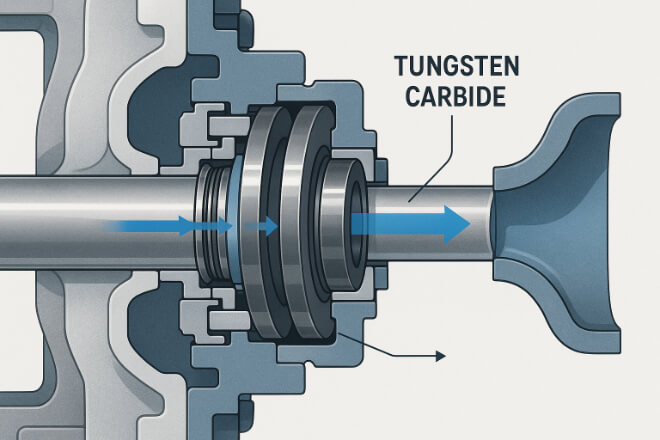

카바이드 씰 링 are used in mechanical seals to prevent leakage between rotating and stationary components.

The ring faces must withstand friction, corrosion, and pressure while maintaining a perfect sealing interface.

Among all materials, tungsten carbide (WC) stands out for its combination of 경도, chemical resistance, and thermal stability.

It can resist aggressive fluids, slurries, and corrosive gases far better than ceramic or stainless steel options.

Two main carbide materials are typically used:

Cobalt-bonded tungsten carbide (WC-Co): Provides excellent mechanical strength and 강인함, suitable for clean fluids and moderate corrosion environments.

Nickel-bonded tungsten carbide (WC-Ni): Offers superior resistance to acids, alkalis, and oxidizing chemicals, making it ideal for aggressive media.

Choosing between them depends on what chemicals the ring will face and under what operating conditions.

Matching Carbide Grades with Chemical Media

Different chemical media attack materials in different ways.

For example, strong acids dissolve metallic binders, while alkaline solutions may cause pitting corrosion or stress cracking.

Below is a practical guide that links typical process media with suitable carbide grades.

| Media Type | Typical Example | 추천 카바이드 등급 | 노트 |

|---|---|---|---|

| Acidic Media | H₂SO₄, HCl, HNO₃ | Nickel-bonded WC | Excellent corrosion resistance; avoid cobalt grades. |

| Alkaline Media | NaOH, NH₄OH | Fine-grain WC-Co | Good mechanical stability; moderate pH tolerance. |

| Hydrocarbon Media | Oils, fuels, solvents | Standard WC-Co | High wear resistance; corrosion is less critical. |

| Oxidizing Media | Peroxides, chlorine | Nickel-bonded WC or SiC | Excellent oxidation resistance required. |

| Abrasive Media | Slurries, sand, pulp | Coarse-grain WC-Co | Improved impact and wear resistance. |

This table helps engineers quickly identify the best match between the chemical media and carbide composition.

Considering pH Range in Seal Ring Selection

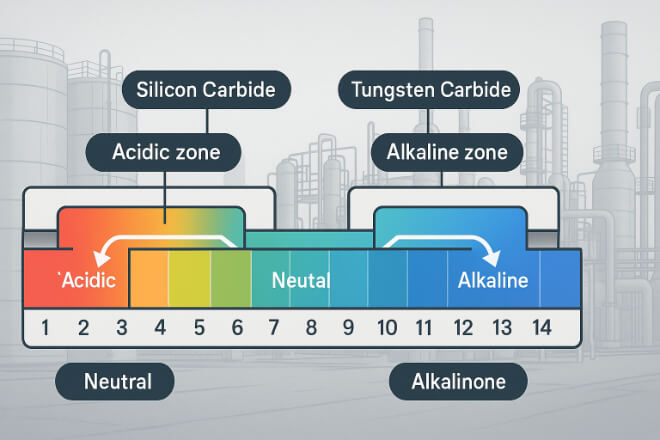

pH is one of the most important factors for corrosion performance.

Carbide materials react differently under acidic, neutral, or alkaline conditions.

pH < 4 (acidic): Nickel-bonded tungsten carbide is best suited. It resists acid corrosion where cobalt grades degrade rapidly.

pH 4–9 (neutral): Both WC-Co and WC-Ni grades can perform well depending on fluid purity.

pH > 9 (alkaline): Cobalt-bonded WC generally performs better, as nickel can be attacked by strong bases.

The challenge is that many industrial processes experience pH fluctuations.

When that happens, using a dual-face design (for example, WC-Ni vs. SiC) can provide extra protection.

Maintaining the correct pH compatibility ensures longer seal life and fewer shutdowns for replacement.

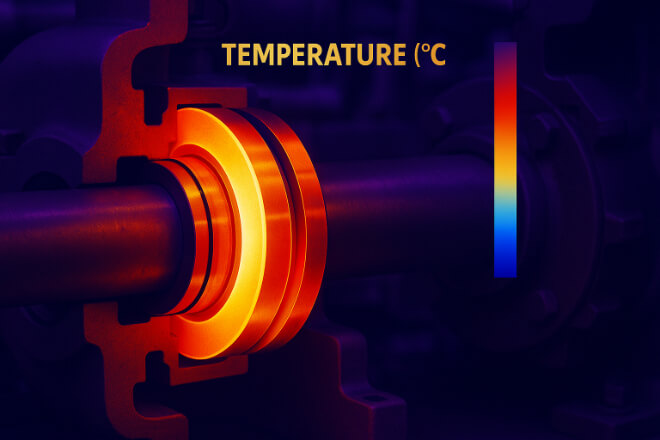

The Temperature Factor: Stability Under Stress

Temperature plays a dual role. It affects both the chemical reactivity and mechanical integrity of carbide seals.

At higher temperatures, binder leaching and thermal oxidation become serious risks.

In general:

Below 150°C: Most carbide grades perform well.

150–250°C: Nickel-bonded WC retains better 내식성, but cobalt grades may soften slightly.

Above 250°C: Consider special grades or coatings (e.g., Cr3C2, TiC) for stability.

Selecting the correct carbide material for the working temperature ensures consistent surface hardness, prevents thermal cracking, and maintains tight sealing clearance.

Mapping Media, pH, and Temperature Together

In real-world systems, all three parameters — media, pH, and temperature — interact.

Here is a simplified selection map for quick decision-making:

| Operating Media | pH Range | Temperature Range (°C) | Best Material Choice |

|---|---|---|---|

| Strong Acid | 1–3 | 0–200 | WC-Ni |

| Mild Acid or Neutral | 4–7 | 0–250 | WC-Ni or WC-Co |

| Alkaline Solution | 8–12 | 0–250 | WC-Co |

| Hydrocarbons / Oils | 6–9 | 0–300 | WC-Co |

| Oxidizing Chemicals | 5–9 | 0–200 | WC-Ni or SiC |

This map can serve as a starting point for specification engineers. Final selection should always consider specific fluid data and operating experience.

Practical Tips for Specifying Carbide Seal Rings

Collect detailed process data: Chemical type, concentration, pH range, and temperature variations.

Consult with your carbide supplier early to determine the right grade and binder type.

Avoid cobalt grades if chloride or oxidizing acids are present.

Ensure compatible counter-face materials — pairing WC with carbon or SiC is often optimal.

Inspect sealing surfaces regularly for binder corrosion or micro-pitting.

Request test certificates or corrosion data for your specific process chemicals.

A good supplier should be able to offer custom-engineered carbide compositions based on your process environment.

결론

Specifying the correct carbide seal ring is more than a material choice — it’s a strategic decision that impacts reliability, uptime, and long-term cost.

By understanding how media, pH, and temperature interact, engineers and managers can ensure their sealing systems perform safely and efficiently under aggressive chemical conditions.

A small adjustment in material specification can mean years of trouble-free operation.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.