Tungsten carbide balls may be small, but in industries where precision and durability matter, they are essential.

From bearings that keep machines running smoothly, to valves that control flow under extreme pressure, to flowmeters that provide accurate readings, tungsten carbide balls deliver performance where steel or other materials often fail.

This article explains why they are used, what benefits they bring, and how decision-makers can weigh cost versus performance when selecting materials.

Why Tungsten Carbide Balls Are Preferred

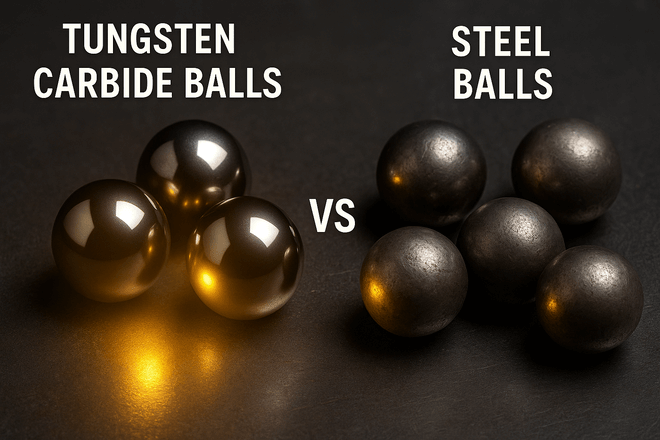

The first question for any industrial buyer is: why use tungsten carbide instead of steel? The answer lies in the material’s unique properties:

경도 close to diamond (above 90 HRA).

높은 내마모성, even in abrasive environments.

부식 저항성, especially in chemicals and seawater.

Strength under load, maintaining roundness and shape.

Long service life, reducing downtime and replacement costs.

These qualities explain why carbide balls are the first choice in industries like 석유와 가스, chemical processing, 항공우주, 그리고 자동차 조작.

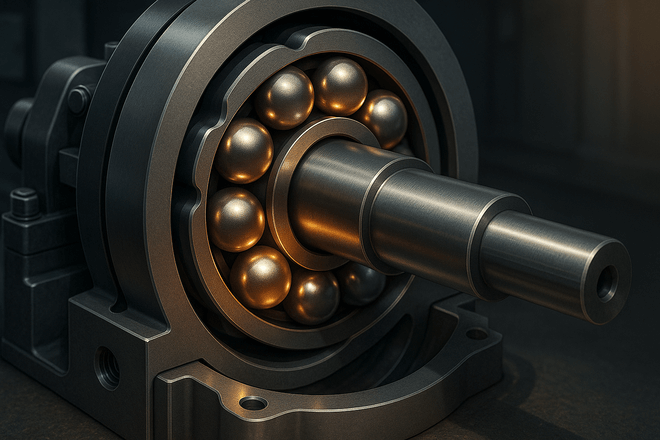

Tungsten Carbide Balls in Bearings

Bearings reduce friction between moving parts and keep machines efficient. For applications where reliability is critical, carbide balls outperform steel:

They resist flattening under heavy loads.

They last longer in high-speed or high-temperature bearings.

They deliver smoother operation, which reduces vibration and noise.

You will find carbide-bearing balls in aerospace turbines, oil drilling tools, wind energy systems, and automotive engines.

For decision-makers, this means better efficiency, higher safety, and fewer shutdowns caused by bearing failure.

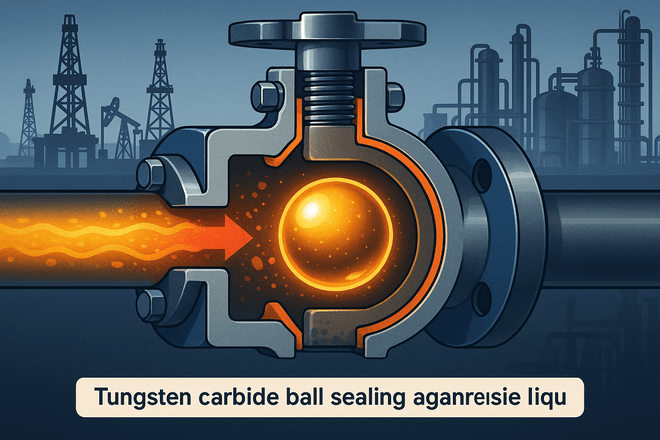

Tungsten Carbide Balls in Valves

Valves control fluid and gas flow in countless industries.

When tungsten carbide balls are used inside check valves, ball valves, or high-pressure control systems, they:

Provide tight sealing and reduce leakage.

Resist corrosion from seawater, acids, and chemicals.

Perform under extreme pressure, making them reliable for oil rigs and refineries.

Downtime caused by valve failure can cost millions in sectors like petrochemicals and offshore drilling.

That’s why carbide is often selected despite its higher upfront cost—it simply avoids expensive failures.

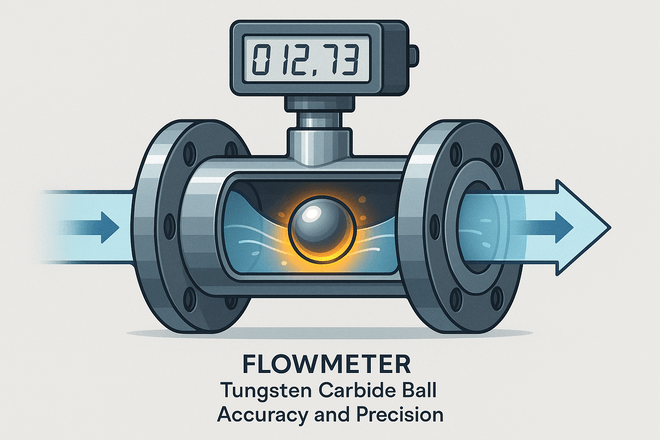

Tungsten Carbide Balls in Flowmeters

Flowmeters measure the movement of liquids and gases, and accuracy is everything. Carbide balls play a role in ensuring reliable readings:

Their perfect roundness helps sensors maintain precision.

They resist wear when fluids contain sand, dirt, or other particles.

They hold up in corrosive or high-temperature environments.

This reliability is crucial in industries like chemical processing, water treatment, and oil exploration, where inaccurate flow readings can lead to safety risks or wasted resources.

Cost vs. Performance: Why Carbide Wins

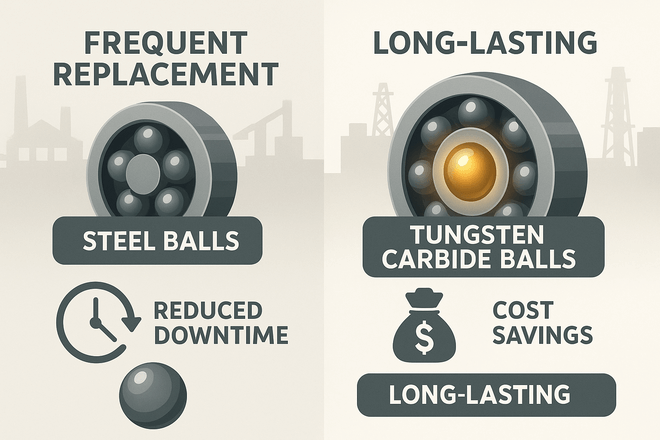

Steel balls are cheaper at first glance, but their shorter life cycle makes them costly in the long run.

Tungsten carbide’s durability lowers replacement frequency, reduces labor costs for maintenance, and keeps machines running longer.

For industries where uptime is critical, carbide delivers higher return on investment (ROI).

Comparison Table: Tungsten Carbide vs Steel Balls

| 특징 | 텅스텐 카바이드 볼 | Steel Balls |

|---|---|---|

| 경도 | Very high (90+ HRA) | Moderate (~60 HRC) |

| 내마모성 | Excellent, long service life | Wears out faster |

| 부식 저항성 | Strong in acids, seawater, chemicals | Limited, prone to rust |

| 응용 프로그램 | Bearings, valves, flowmeters, oil & gas | General machinery |

| Overall Value | Higher ROI, less downtime | Lower upfront, higher long-term costs |

마지막 생각

Tungsten carbide balls provide industries with an edge in reliability, safety, and performance.

In bearings, valves, and flowmeters, they prove their worth every day by reducing failures, extending equipment life, and keeping systems efficient.

For decision-makers, the message is clear: while steel may look cheaper, tungsten carbide delivers the better long-term solution.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.