High-RPM compressors are essential components in a variety of industrial applications, including 석유와 가스, refrigeration, and air compression systems.

These compressors operate at high speeds and often handle abrasive, corrosive, and high-pressure fluids.

The guide supports in these compressors are key to maintaining stable operations, and their performance is heavily dependent on the materials used.

텅스텐 카바이드 부싱 are increasingly being specified for high-RPM compressor guide supports due to their exceptional 내마모성, high hardness, and resistance to thermal expansion.

This blog explores why tungsten carbide bushings are ideal for high-RPM compressors and how they contribute to better performance, efficiency, and reliability.

The Challenges of High-RPM Compressors

High-RPM compressors face unique challenges due to their high operating speeds, which create increased friction, heat, and wear on components such as guide supports. These challenges include:

Key challenges include:

High rotational speeds leading to excessive friction and wear

Heat generation from constant high-speed operation

Vibration and misalignment due to rapid movements

Exposure to corrosive fluids like oils, refrigerants, and industrial gases

Abrasion from solid particles in the fluids being compressed

Due to these conditions, compressors require bushings that can withstand the combined effects of high speed, pressure, heat, and chemical exposure.

Why Tungsten Carbide Bushings Are the Best Choice for High-RPM Compressor Guide Supports

Tungsten carbide bushings offer a variety of benefits that make them well-suited for high-RPM compressor guide supports.

Their exceptional physical properties allow them to perform well in demanding environments where traditional materials would fail.

Key benefits of tungsten carbide bushings:

높은 내마모성: Tungsten carbide is extremely hard and resistant to wear from friction and abrasive particles in the fluids being compressed.

부식 저항성: The material is highly resistant to corrosion, making it ideal for applications that involve exposure to oils, chemicals, and refrigerants.

Thermal stability: Tungsten carbide maintains its properties even under high temperatures, which is crucial for compressors that operate continuously at high speeds and generate significant heat.

Low friction: The smooth surface of tungsten carbide reduces friction, which helps decrease energy consumption and wear on other moving parts.

Long service life: Tungsten carbide bushings are known for their durability and long lifespan, reducing the need for frequent maintenance and replacements.

These advantages make tungsten carbide bushings a cost-effective solution for improving the reliability and performance of high-RPM compressors.

How Tungsten Carbide Bushings Improve Compressor Performance

The performance of high-RPM compressors depends on the integrity and efficiency of the components involved, particularly the guide supports.

Tungsten carbide bushings play a crucial role in enhancing compressor performance by ensuring stable operation and reducing the risks of failure.

How tungsten carbide improves performance:

Enhanced stability: The 경도 그리고 밀도 of tungsten carbide reduce vibrations and maintain precise alignment of compressor components.

Reduced wear and tear: Tungsten carbide’s wear resistance ensures that the guide supports last longer, even under heavy-duty conditions, leading to fewer breakdowns and less maintenance.

Improved energy efficiency: Lower friction means that the compressor motor has to work less to maintain the same operational speed, leading to reduced energy consumption.

Increased reliability: The resistance to thermal expansion and corrosion helps maintain the structural integrity of the compressor, even under extreme conditions.

Overall, using tungsten carbide bushings in high-RPM compressors leads to more efficient, reliable, and long-lasting equipment.

Tungsten Carbide Grades for Compressor Guide Supports

When selecting tungsten carbide bushings for high-RPM compressors, the choice of binder and grain size is essential to achieving the best performance.

1). Recommended grades for high-RPM compressor guide supports:

1.1). WC-Co (Cobalt Binder):

Strengths: High 내마모성 그리고 강인함, suitable for general high-speed applications.

Best for: Standard compressor applications where wear resistance is a top priority, and corrosion is less of a concern.

1.2). WC-Ni (Nickel Binder):

Strengths: Superior 내식성, ideal for applications involving exposure to corrosive fluids.

Best for: Compressors handling chemicals, oils, or refrigerants, where corrosion is a major concern.

2). Tungsten Carbide Grade Comparison Table

| 등급 | 접합재 | 주요 이점 | 최적의 지원서 |

|---|---|---|---|

| WC-6Co | Cobalt | High wear resistance and toughness | General high-speed compressors |

| WC-12Co | Cobalt | Toughness and wear resistance | Heavy-duty compressors |

| WC-Ni | Nickel | 탁월한 내식성 | Compressors handling oils, refrigerants, and chemicals |

Common Failure Modes in High-RPM Compressors

High-RPM compressors, like any rotating machinery, are susceptible to various failure modes that can affect performance and reliability. Even with tungsten carbide bushings, certain conditions may cause issues.

1). Common failure modes include:

Abrasive wear from friction caused by high-speed rotation

Corrosion from exposure to chemicals or refrigerants

Thermal shock from rapid temperature fluctuations during startup or shutdown

Vibration-induced wear or misalignment

Cracking or chipping from excessive mechanical stress

By using tungsten carbide bushings and implementing preventive maintenance, these issues can be minimized.

2). Failure Mode Summary Table

| Failure Mode | Cause | 해결책 |

|---|---|---|

| 연마 마모 | Friction from moving parts | Use WC-Co or WC-Ni grades |

| Corrosion | Exposure to chemicals or refrigerants | Choose WC-Ni for superior corrosion resistance |

| Cracking | Excessive mechanical stress or thermal shock | Ensure proper alignment and gradual startup |

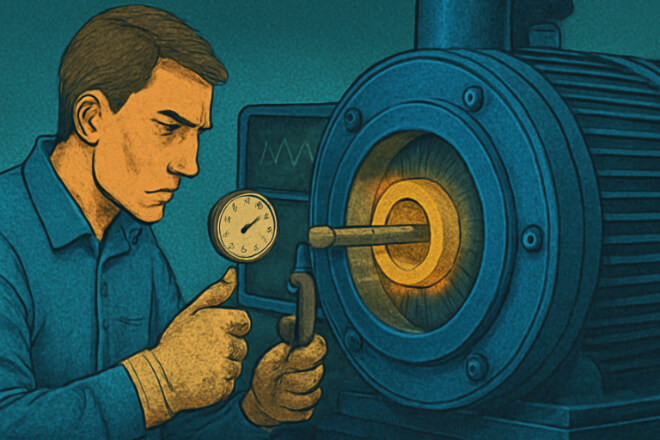

Maintenance and Inspection Tips for High-RPM Compressors

Regular maintenance and inspection of high-RPM compressors are crucial to keeping the equipment running smoothly. Here are some key maintenance tips:

Best practices include:

Inspect bushings for signs of wear, cracking, or corrosion

Ensure proper alignment and clearance during installation

Monitor vibrations and temperatures regularly

Use clean lubrication and cooling systems

Replace bushings before they reach critical wear stages

Adhering to these practices will help maintain efficient compressor operation and extend the lifespan of the bushings.

Choosing the Right Supplier for High-RPM Compressor Bushings

The quality of tungsten carbide bushings is heavily dependent on the supplier. It is essential to work with a supplier who understands the unique needs of high-RPM compressors.

Key supplier criteria:

Experience with high-RPM compressor applications

Ability to supply WC-Ni and WC-Co grades

Expertise in high-밀도 HIP sintering for optimal durability

Reliable delivery and support for OEM customization

Comprehensive testing and quality control procedures

A reliable supplier ensures that the bushings are of the highest quality, reducing downtime and increasing compressor reliability.

결론

Tungsten carbide bushings are the ideal solution for high-RPM compressors due to their high wear resistance, corrosion resistance, and ability to withstand high temperatures.

By selecting the right grade, maintaining proper operational conditions, and working with a trusted supplier, companies can ensure the efficient, reliable, and long-lasting performance of their compressors.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.