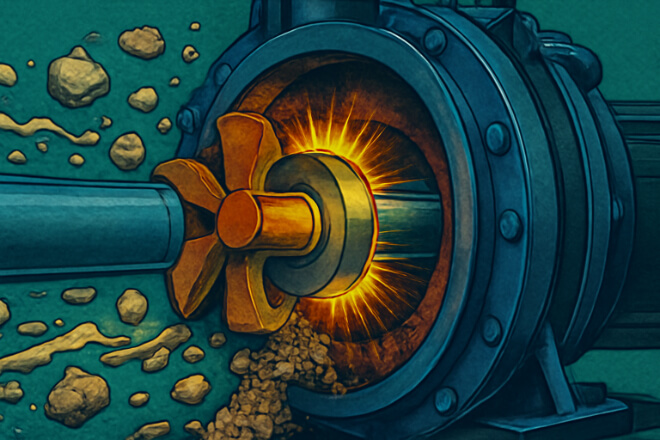

Mining dewatering and tailings pumps play a crucial role in the mining industry.

These pumps are responsible for moving water, slurry, and tailings away from the 채광 site, often in harsh, abrasive, and corrosive environments.

To ensure optimal performance and longevity, many mining operations use tungsten carbide bushings in their dewatering and tailings pumps.

These bushings provide durability, 내마모성, and corrosion protection, which are essential in maintaining pump efficiency and minimizing downtime.

Challenges Faced by Dewatering and Tailings Pumps

Dewatering and tailings pumps in the mining industry are exposed to some of the most difficult operating conditions. These pumps often deal with:

Abrasive materials such as sand, silt, and rock particles

High flow rates of slurry and tailings

Corrosive fluids including acids and salts from mining operations

Vibration and heavy loads from constant pumping under high pressure

These extreme conditions can cause rapid wear and premature failure of pump components, particularly the bushings. Using traditional materials like steel or bronze can lead to frequent maintenance and part replacements.

Why Tungsten Carbide Bushings Are Ideal for Mining Pumps

Tungsten carbide bushings are well-suited to the tough environments of dewatering and tailings pumps. They are known for their:

Key advantages:

훌륭한 내마모성 against solid particles, sand, and slurry

우수한 내식성, especially in acidic or saline conditions

높은 경도 that protects against erosion and abrasive wear

Low friction that helps reduce energy consumption and improve efficiency

High compressive strength, preventing deformation under high pressure

Long service life, reducing downtime and maintenance costs

These characteristics make tungsten carbide bushings an excellent choice for mining pumps, ensuring smoother and more reliable operation.

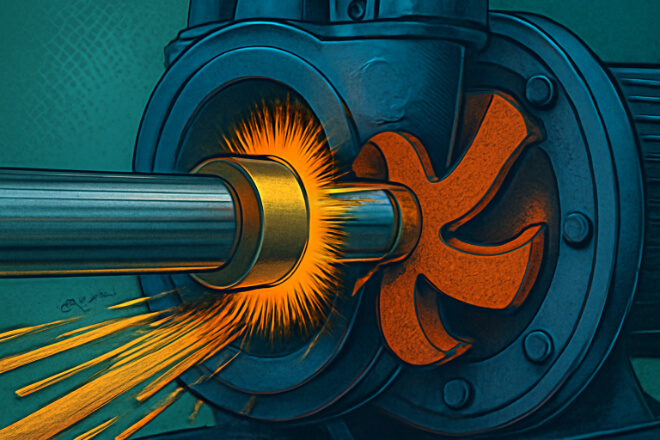

How Tungsten Carbide Bushings Improve Pump Performance

In dewatering and tailings pumps, the bushings are critical components that support the rotating shaft and reduce friction. Tungsten carbide bushings offer several improvements to the performance of these pumps:

Performance improvements include:

Reduced maintenance costs: Tungsten carbide bushings have a much longer lifespan compared to traditional materials, reducing the need for frequent replacements.

Increased reliability: The high wear and 내식성 of tungsten carbide ensures that the pump runs smoothly, even in abrasive slurry and corrosive environments.

Enhanced efficiency: Low friction reduces the load on the motor, helping to save energy and increase the overall efficiency of the pump.

Stable operation: Tungsten carbide maintains its integrity under high pressure, preventing shaft misalignment and ensuring smooth rotation.

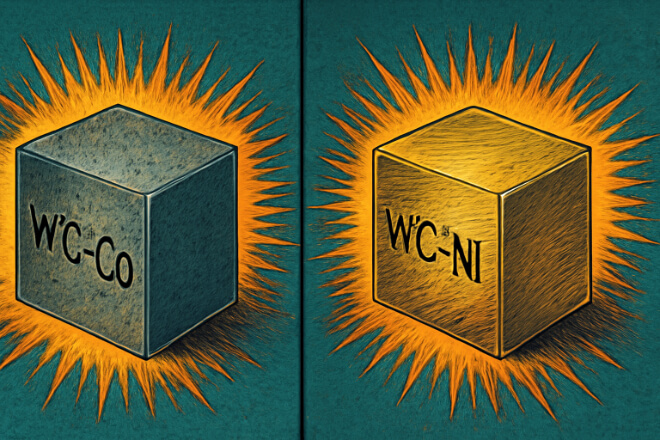

Tungsten Carbide Grades for Dewatering and Tailings Pumps

When selecting tungsten carbide bushings for mining applications, the binder type and grain size are important factors to consider.

1). Recommended Tungsten Carbide Grades:

1.1). WC-Co (Cobalt Binder):

가장 좋은 내마모성 in highly abrasive conditions, such as slurry and tailings handling.

Provides high 경도 and toughness, making it ideal for dewatering pumps handling sand, silt, and other abrasive materials.

1.2). WC-Ni (Nickel Binder):

우수한 내식성 in acidic or saline environments.

Ideal for pumps handling tailings with a high level of chemical content, ensuring long service life in harsh conditions.

2). Tungsten Carbide Grade Comparison Table

| 등급 | 접합재 | 장점 | 가장 적합한 |

|---|---|---|---|

| WC-6Co | Cobalt | 높은 내마모성 | Slurry and tailings with high solids content |

| WC-12Co | Cobalt | Better toughness | Heavy-duty dewatering pumps |

| WC-Ni | Nickel | 탁월한 내식성 | Tailings handling in acidic or saline conditions |

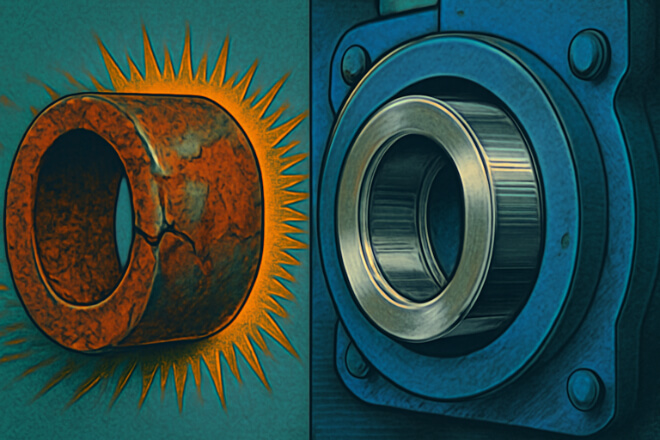

Common Failure Modes in Dewatering and Tailings Pumps

Despite the durability of tungsten carbide bushings, pumps in mining environments can still face failures. Understanding the common failure modes is crucial for preventing downtime.

1). Typical failure types:

Abrasive wear from sand, silt, and other solid particles

Corrosion caused by acidic or saline media

Thermal shock due to temperature changes during startup and shutdown

Chipping or cracking from mechanical stress or misalignment

Erosion from high-pressure flow and slurry impact

By choosing the right tungsten carbide grade and maintaining proper pump conditions, these issues can be minimized.

2). Failure Mode Summary Table

| Failure Mode | Cause | Prevention |

|---|---|---|

| 연마 마모 | Sand and solid particles | Use WC-Co or WC-Ni for abrasive conditions |

| Corrosion | Acidic or saline media | Use WC-Ni for corrosion resistance |

| Chipping | Shock loads or misalignment | Ensure proper alignment and load distribution |

Maintenance and Inspection Tips for Dewatering and Tailings Pumps

Regular maintenance is critical to extending the service life of tungsten carbide bushings. Proper inspection and care can prevent failures and reduce the frequency of replacements.

Best practices for maintenance:

Inspect for early signs of wear or corrosion

Check alignment and clearance during shutdowns

Ensure proper filtration of slurry to prevent particle buildup

Use clean lubrication or flushing systems

Replace bushings before severe wear occurs

Conduct vibration and temperature checks regularly

Following these practices will help maximize the efficiency and reliability of your pumps.

Choosing the Right Supplier for Mining Applications

Choosing the right supplier ensures that your tungsten carbide bushings meet the necessary quality standards and are fit for harsh mining conditions.

What to look for in a supplier:

Extensive experience with 채광 applications

Ability to provide WC-Ni and WC-Co grades

높은-밀도 HIP sintering for durability

Comprehensive testing capabilities (경도, density, microstructure)

Custom bushing designs for specific pump models

Short lead times and reliable delivery schedules

A reliable supplier can significantly reduce downtime and maintenance costs while improving pump performance.

결론

Tungsten carbide bushings are essential components in mining dewatering and tailings pumps.

Their exceptional wear and corrosion resistance make them ideal for the harsh environments found in mining operations.

By selecting the right grade, maintaining proper pump conditions, and working with a reliable supplier, mining operators can extend pump life and reduce operating costs.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.