Compressors and turbo machinery are essential in industries such as oil and gas, chemical processing, marine, and power generation.

These machines operate under high pressure, heat, and vibration, and even a small seal failure can lead to expensive downtime and safety risks.

To ensure reliable performance, many companies choose tungsten carbide seal rings.

This article explains why tungsten carbide is the preferred choice, its advantages over other materials, and best practices for decision-makers.

Why Seal Rings Matter in Compressors and Turbo Machinery

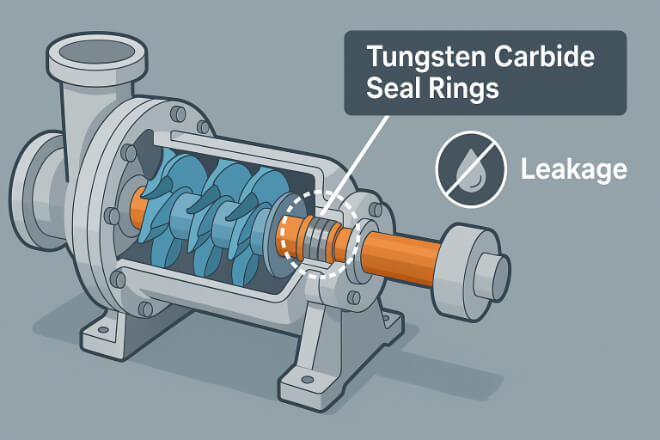

Seal rings in compressors and turbines perform critical tasks:

Prevent leaks of gas, air, or fluids.

Protect bearings and rotors from contamination.

Reduce friction and wear inside high-speed equipment.

Maintain efficiency under pressure and temperature changes.

A strong, durable seal ring ensures safe, reliable, and energy-efficient machinery.

텅스텐 카바이드 씰 링의 주요 특성

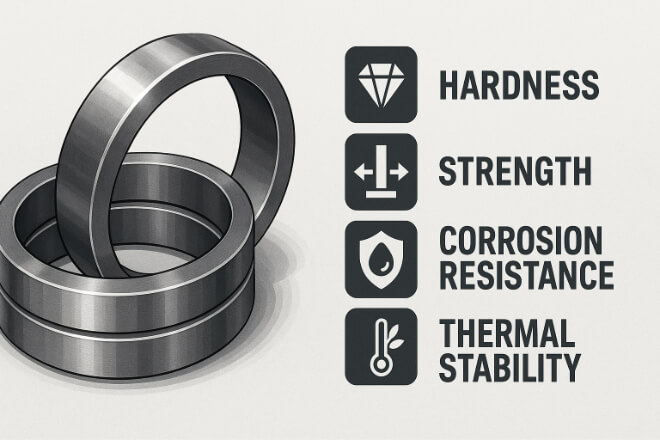

Tungsten carbide is a compound of tungsten and carbon, often bonded with cobalt or nickel. Its properties include:

극심한 경도 → 마찰과 입자로 인한 마모를 방지합니다.

높은 압축 강도 → Handles heavy loads and high pressure.

열 안정성 → Performs reliably under high temperatures.

부식 저항성 → Protects against chemicals and gases.

치수 안정성 → Maintains accurate sealing surfaces.

These properties make tungsten carbide ideal for compressors and turbo machinery operating in harsh conditions.

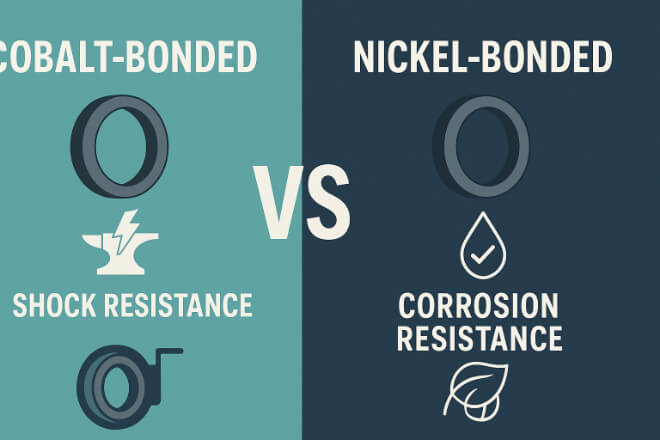

코발트 결합 텅스텐 카바이드 vs 니켈 결합 텅스텐 카바이드

1) 코발트 결합 텅스텐 카바이드

2) 니켈 결합 텅스텐 카바이드

우수한 내식성.

Ideal for chemical plants, marine systems, and gas compressors.

Choosing the right binder ensures long service life and optimal performance.

다른 씰 재료에 비해 장점

| 특징 | 텅스텐 카바이드 | 세라믹 | 강철 |

|---|---|---|---|

| 내마모성 | Excellent for abrasives | 보통의 | Poor in slurry |

| 강인함 | 높고 충격에 강함 | Low, brittle under impact | 보통의 |

| 부식 저항성 | Good, nickel grades excel | Excellent in acids | Poor in chemicals |

| Thermal performance | Excellent at high heat | 좋은 | 보통의 |

| 서비스 수명 | 오래 지속되는 | 보통의 | 짧은 |

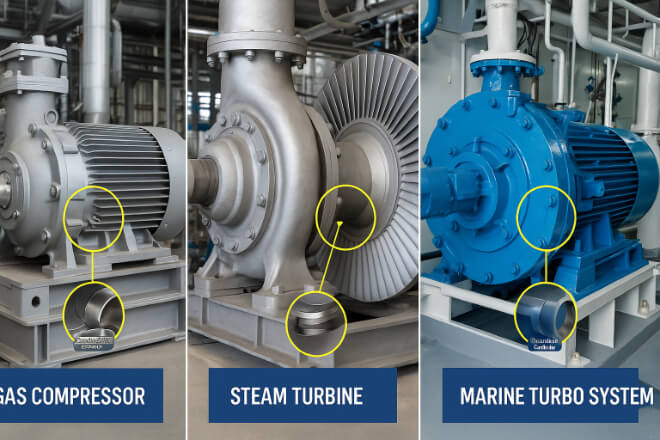

Applications in Compressors and Turbo Machinery

텅스텐 카바이드 씰 링 are widely used in:

Gas compressors → Prevent leaks under high pressure.

Steam turbines → Maintain tight seals during temperature changes.

Marine turbo systems → Resist seawater corrosion and vibration.

Chemical processing compressors → Handle aggressive chemicals without failure.

Power generation turbines → Improve energy efficiency and reduce maintenance.

비용 대 장기적 가치

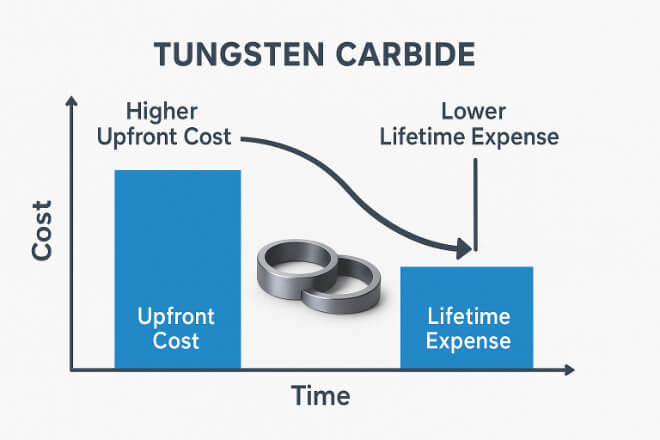

While tungsten carbide seal rings may cost more initially, they:

Last longer than steel or ceramic alternatives.

Require fewer replacements, lowering spare part costs.

Reduce downtime, improving productivity.

Protect equipment, extending compressor or turbine life.

For decision-makers, the life cycle cost is often lower with tungsten carbide despite its higher upfront price.

환경적 이점

Tungsten carbide is recyclable, reducing material waste. Reusing tungsten reduces mining demand and supports sustainability goals.

Fewer replacements also mean fewer seals in landfills and less manufacturing energy used over time.

텅스텐 카바이드 씰 링 사용 모범 사례

올바른 바인더를 선택하세요 → 니켈은 부식을 방지하고, 코발트는 충격에 강합니다.

조심스럽게 설치하세요 → Avoid scratches or misalignment that cause leaks.

Ensure proper lubrication → Reduces heat and friction.

정기적으로 검사하세요 → Spot wear early to prevent costly downtime.

Work with trusted suppliers → Ensure material quality and proper specifications.

의사결정자를 위한 주요 정보

Tungsten carbide seal rings are essential for compressors and turbo machinery under high pressure, heat, and vibration.

Nickel-bonded grades excel in corrosive environments, while cobalt-bonded grades handle shock better.

Their durability, recyclability, and efficiency offer better ROI compared to other materials.

Choosing tungsten carbide reduces downtime, maintenance, and environmental impact.

결론

In compressors and turbo machinery, seal reliability is critical. Tungsten carbide seal rings provide the hardness, strength, and corrosion resistance required for long-term performance in demanding industries.

For decision-makers, using tungsten carbide is a smart investment that balances cost, sustainability, and operational efficiency.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.