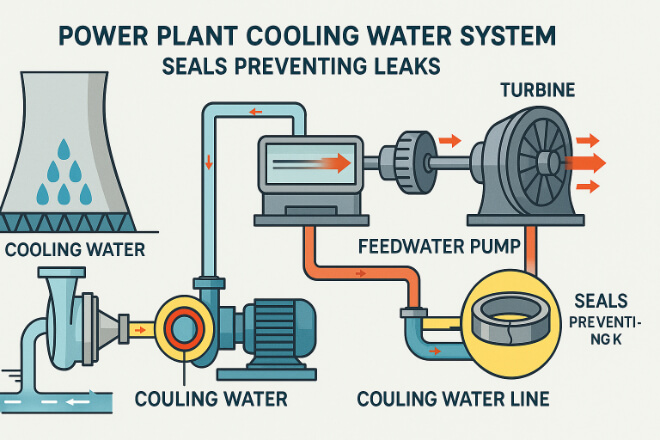

Power plants rely on cooling water systems to manage heat and keep turbines, pumps, and generators running safely.

Any leak or failure in these systems can lead to downtime, efficiency loss, or environmental damage.

텅스텐 카바이드 씰 링 are one of the most reliable materials for pumps and compressors in cooling water systems.

This article explains why they are essential, their benefits, and how to use them effectively.

Why Cooling Water Systems Need Reliable Seals

Prevent leaks → Protect equipment and reduce water loss.

Maintain efficiency → Proper seals help pumps operate at full performance.

Reduce downtime → Reliable seals minimize unplanned maintenance.

Avoid contamination → Prevents cooling water from mixing with other fluids.

Protect the environment → Stops harmful discharges into natural water sources.

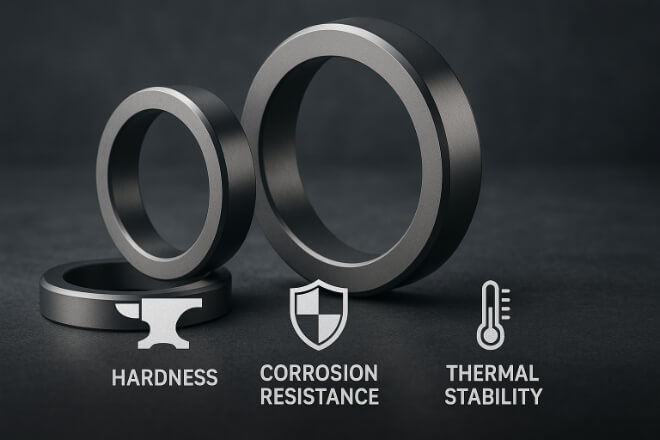

텅스텐 카바이드 씰 링의 주요 특성

Tungsten carbide is a compound of tungsten and carbon, bonded with cobalt or nickel. It offers:

다른 씰 재료에 비해 장점

| 특징 | 텅스텐 카바이드 | 세라믹 | 강철 |

|---|---|---|---|

| 내마모성 | Excellent for abrasives | 보통의 | 가난한 |

| 부식 저항성 | High (nickel grades) | Very Good | 낮은 |

| 강인함 | 높고 충격에 강함 | 낮음, 취성 | 보통의 |

| Thermal Performance | Excellent at high heat | 좋은 | 보통의 |

| Service Life | 오래 지속되는 | 보통의 | 짧은 |

Applications in Power Plant Cooling Water Systems

텅스텐 카바이드 씰 링은 다음 분야에서 널리 사용됩니다.

Main cooling water pumps → Ensure reliable, leak-free operation.

Circulating pumps → Maintain water movement for turbine efficiency.

Auxiliary systems → Protect small pumps in control circuits.

Brackish water systems → Resist corrosion in coastal plants.

Backup generators → Provide sealing under varying temperatures and pressures.

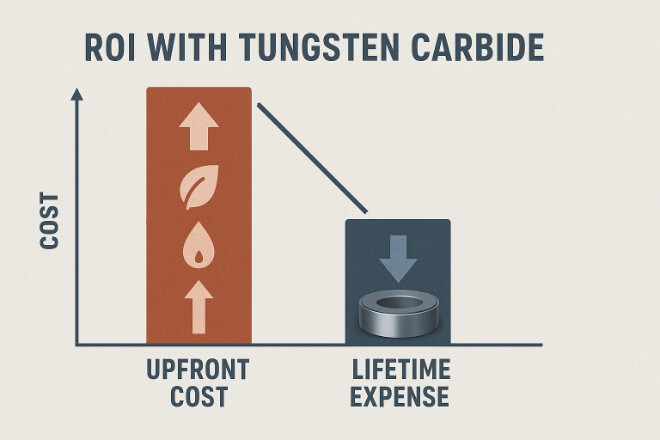

비용 대 장기적 가치

Although tungsten carbide seal rings cost more upfront:

Reduce downtime → Fewer failures mean less lost production.

Lower maintenance → Longer service life reduces labor and spare parts.

Protect equipment → Prevents damage to expensive pumps and turbines.

Improve ROI → Long-term savings offset initial costs.

Environmental and Safety Benefits

Leak prevention → Protects local water sources and ecosystems.

Recyclable material → Supports power plants’ sustainability goals.

Efficient performance → Reduces wasted energy in pumps and compressors.

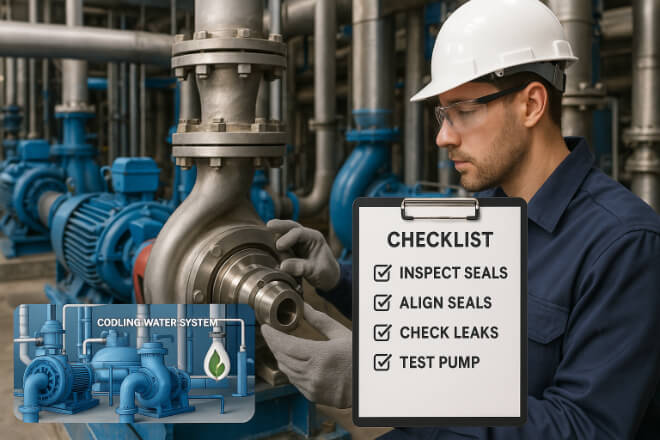

텅스텐 카바이드 씰 링 사용 모범 사례

올바른 바인더를 선택하세요 → Nickel for brackish or chemical-rich water, cobalt for vibration-heavy pumps.

Inspect seals regularly → 조기에 마모를 감지하여 고장을 방지합니다.

Ensure proper installation → Avoid scratches or misalignment during assembly.

Maintain proper lubrication → Prevent dry running that can damage seals.

Work with trusted suppliers → Get quality materials and accurate specifications.

의사결정자를 위한 주요 정보

텅스텐 카바이드 씰 링 are the best choice for power plant cooling water systems.

They combine durability, 내식성, 그리고 강인함 for long-term performance.

Higher upfront cost delivers better ROI through reduced downtime and maintenance.

Proper selection and care ensure reliable, leak-free operation.

결론

Power plant cooling water systems demand seals that can perform under pressure, temperature shifts, and corrosive conditions.

Tungsten carbide seal rings deliver the strength and reliability required to keep operations efficient and safe.

For decision-makers, investing in tungsten carbide ensures long-term savings, environmental protection, and operational reliability.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.