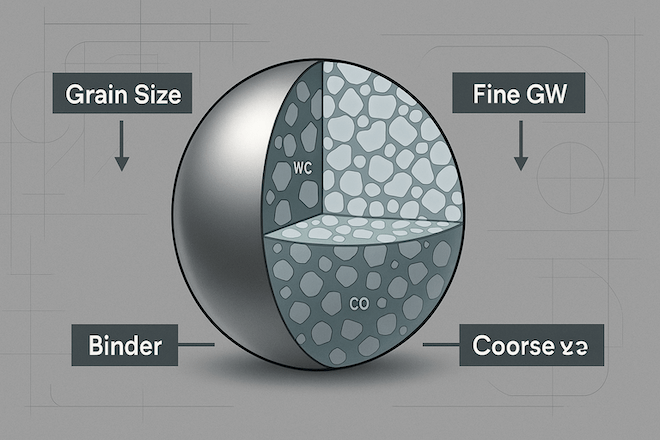

Tungsten carbide balls are known for their extreme hardness, high wear resistance, and long life. But what many people don’t realize is that their performance depends not only on the basic tungsten carbide material, but also on 입자 크기 그리고 바인더 함량.

In this guide, we will explain how grain size and binder affect carbide ball properties, performance, and best applications.

What Is Grain Size in Tungsten Carbide Balls?

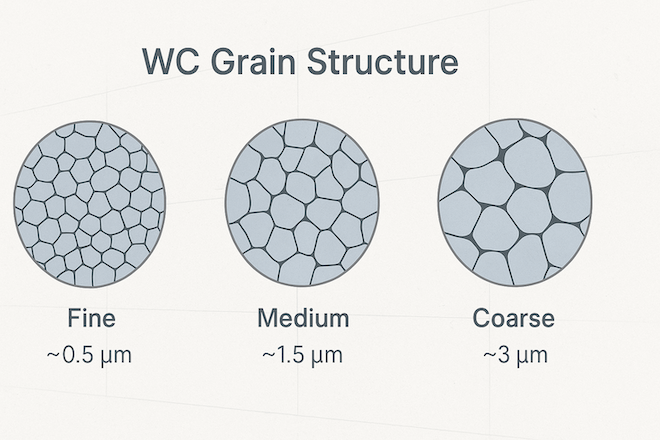

Grain size means the average size of the tungsten carbide (WC) particles inside the ball. It is usually measured in microns.

Fine grain: < 1 micron

Medium grain: 1–3 microns

Coarse grain: > 3 microns

Why it matters:

Simple example:

A fine-grain ball is ideal for precision measurement tools, while a coarse-grain ball is better for impact-heavy applications like mining valves.

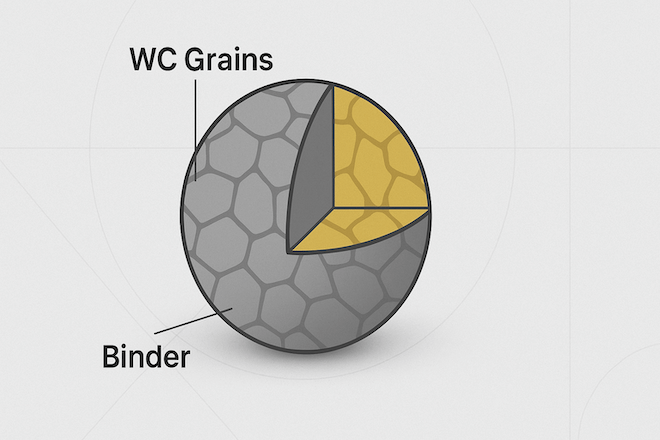

What Is Binder in Tungsten Carbide Balls?

The binder is the metal that holds WC grains together, usually cobalt (Co) or nickel (Ni). The binder content is given in percentage by weight.

Common binder levels:

Low binder (3–6%) → harder, more wear-resistant.

High binder (10–15%) → tougher, better for impact.

Why it matters:

More binder improves toughness but slightly reduces hardness.

Less binder increases hardness but reduces shock resistance.

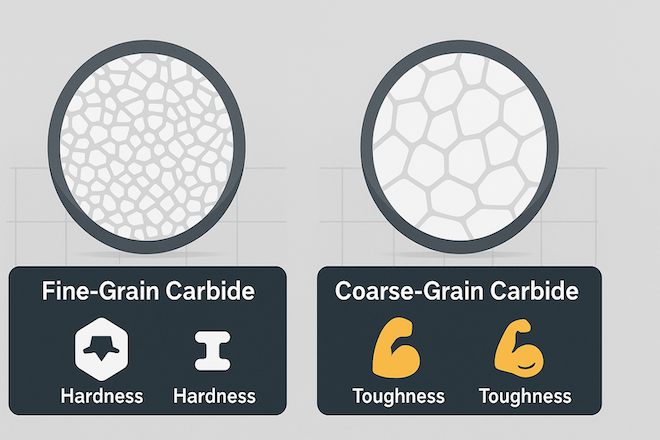

How Grain Size Affects Performance

Fine grain carbide balls:

Very high hardness.

Excellent wear resistance.

Best for precision bearings, gauges, and micrometers.

Coarse grain carbide balls:

Lower hardness but higher toughness.

Better for high-impact or shock-load applications like oil & gas valves.

How Binder Content Affects Performance

Low binder carbide balls:

Very hard, long-lasting in abrasive environments.

Can chip under heavy shock.

High binder carbide balls:

Absorbs more impact without breaking.

거친 환경에서는 더 빨리 마모됩니다.

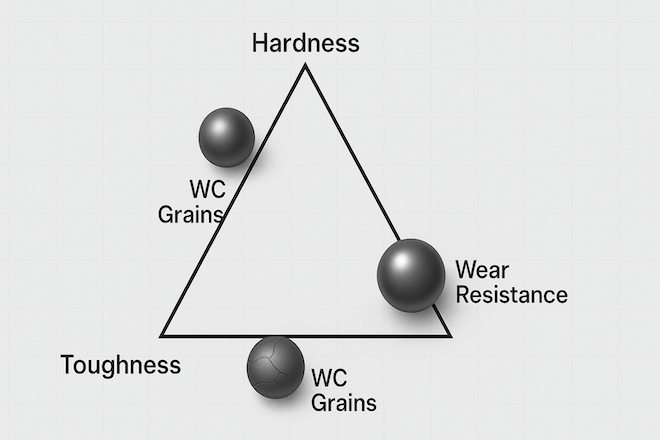

Finding the Right Balance of Grain Size and Binder

The best carbide ball is a balance between hardness and toughness:

High hardness + low binder + fine grain → best for precision and wear resistance.

High toughness + high binder + coarse grain → best for impact and heavy loads.

실제 사례

Fine grain + low binder → Used in aerospace gyroscopes for ultra-precise balance.

Medium grain + medium binder → Used in high-speed measuring equipment.

Coarse grain + high binder → Used in oil drilling valves for impact resistance.

Tips for Selecting Carbide Balls Based on Grain Size and Binder

Check application type – precision or impact.

Match grain size to wear or shock resistance needs.

Match binder content to environment conditions.

Consult supplier for custom grades.

마지막 생각

Understanding grain size and binder content is key to getting the best performance from tungsten carbide balls. The right combination means longer life, better efficiency, and lower replacement costs.

If you need tungsten carbide balls optimized for your application, 다시 올리기 can help with custom grades, sizes, and tolerances.