Tungsten carbide balls are small, spherical components made from an extremely hard material called tungsten carbide. These balls are used in many industries because of their excellent hardness, wear resistance, and strength. If you’re new to the world of tungsten carbide balls, this guide will help you understand what they are, how they’re made, and where they’re used.

텅스텐 카바이드란 무엇인가?

Tungsten carbide is a chemical compound made of tungsten (W) and carbon (C). It is one of the hardest materials in the world—almost as hard as diamond. Because of this, it is often used to make tools and parts that must resist wear, heat, and pressure.

When this material is shaped into a ball, it becomes a high-performance part for demanding applications like bearings, valves, measuring devices, and more.

How Are Tungsten Carbide Balls Made?

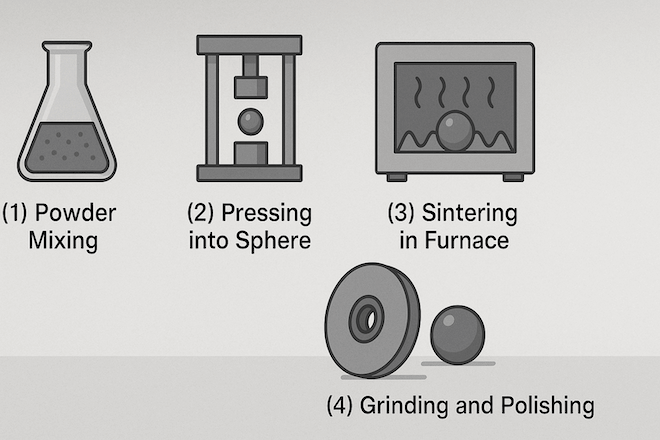

The production of tungsten carbide balls involves several technical steps:

Powder Mixing

Fine tungsten and carbon powders are mixed together.Pressing into Shape

The powder is pressed into a round ball shape using a mold.소결

The shaped ball is heated in a furnace at over 1400°C to harden it.Grinding and Polishing

After sintering, the ball is ground and polished to meet size and surface requirements.

These steps ensure the final balls are strong, smooth, and precise.

Main Properties of Tungsten Carbide Balls

Tungsten carbide balls are popular because of their unique properties:

극심한 경도 – Much harder than steel.

높은 내마모성 – They last longer under friction.

훌륭한 부식 저항성 – They resist rust and chemicals.

높은 밀도 – They are very heavy and solid.

좋은 열 안정성 – They perform well at high temperatures.

Tight 용인 – They can be produced with very precise sizes.

These qualities make them ideal for long-term use, even in harsh environments.

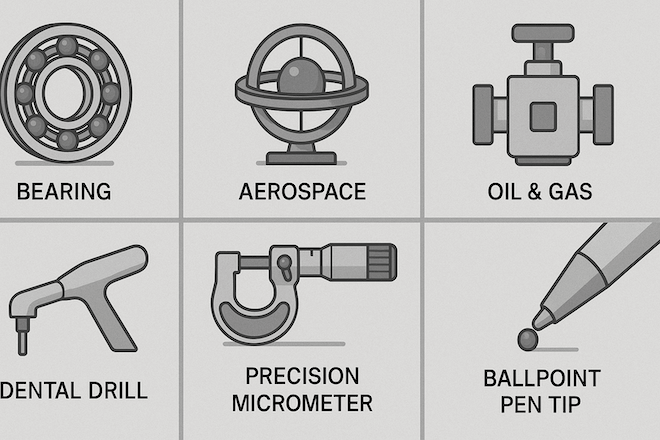

Where Are Tungsten Carbide Balls Used?

Tungsten carbide balls are used in many different fields. Here are some examples:

| 산업 | 애플리케이션 |

|---|---|

| Bearings | For high-speed, high-load mechanical parts |

| 항공우주 | In gyroscopes and navigation systems |

| 석유 및 가스 | For valves and measurement tools |

| 의료기기 | In dental drills and precision parts |

| Industrial Machines | In ball screws, slides, and measuring tools |

| Ink Pens | As the ball tips in ballpoint pens |

No matter the industry, tungsten carbide balls are used wherever precision and durability are important.

Tungsten Carbide Balls vs. Steel Balls

You might wonder why someone would choose tungsten carbide balls over regular steel balls. Here’s a simple comparison:

| 특징 | 텅스텐 카바이드 볼 | Steel Balls |

|---|---|---|

| 경도 | 매우 높음 | 중간 |

| 내마모성 | 훌륭한 | 좋은 |

| 비용 | 더 높은 | 낮추다 |

| 무게 | Heavier | Lighter |

| Lifespan | Longer | 더 짧은 |

If you need long-lasting, high-performance parts, tungsten carbide balls are the better choice.

Common Sizes and Tolerances

Tungsten carbide balls come in many sizes. Common diameters range from 0.5 mm to 50 mm. They can also be made with different grades of tolerance—meaning how exact the size is.

| 직경 범위 | 일반적인 사용 |

|---|---|

| 0.5 mm – 3 mm | Pens, medical tools |

| 3 mm – 10 mm | Bearings, measuring tools |

| 10 mm – 50 mm | Valves, oil & gas components |

Tolerance can be as tight as ±0.002 mm, depending on your needs.

How to Choose the Right Tungsten Carbide Ball

Here are a few tips for selecting the best ball for your needs:

Know Your Application

Choose based on where and how the ball will be used.Select the Right Grade

Some grades are harder; others are tougher. Pick what suits your work best.Check the Size and Tolerance

Make sure the ball fits your equipment precisely.Ask Your Supplier

A trusted supplier can guide you to the best option.

결론

Tungsten carbide balls are powerful tools in many industries. They offer superior hardness, wear resistance, and long service life. Whether you work in engineering, manufacturing, oil & gas, or medical devices, these balls provide performance you can rely on.

If you’re looking for high-quality tungsten carbide balls, make sure to work with a professional supplier who can offer custom sizes, tight tolerances, and expert advice.