In industries such as oil and gas, marine, chemical, and power generation, seal rings are small but vital components. Their job is to prevent leaks, protect equipment, and ensure safety.

Many companies focus only on the upfront price of seal rings when making purchase decisions. But the true cost is not just the purchase price—it is the life cycle cost.

This article explores how tungsten carbide seal rings perform when analyzed over their full life cycle.

We will look at initial cost, maintenance, downtime, service life, and recycling value to help decision-makers see why tungsten carbide is often the smarter investment.

What Is Life Cycle Cost Analysis?

Life cycle cost analysis (LCCA) is a method to measure the total cost of owning and using a product over its lifetime. For seal rings, this includes:

Initial purchase cost

Installation cost

Operating performance

Maintenance and repair cost

Downtime costs from failures

Replacement frequency

Recycling or disposal value

For decision-makers, this approach gives a clear picture of long-term value rather than short-term savings.

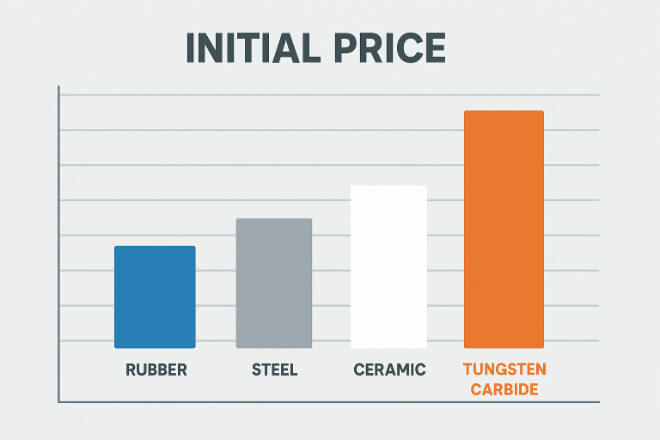

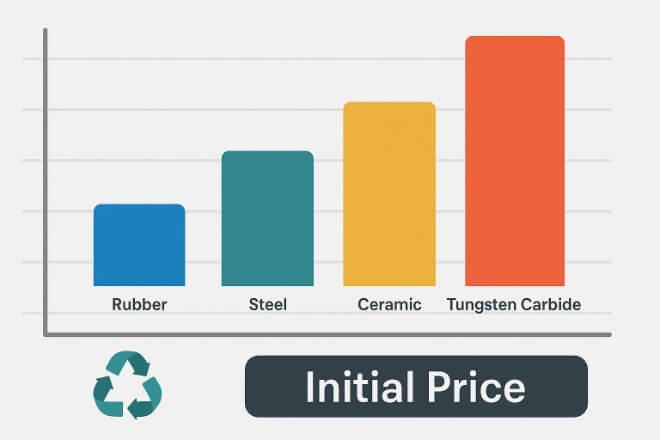

Initial Cost of Tungsten Carbide Seal Rings

Compared with rubber or steel seals, tungsten carbide seal rings are more expensive upfront. The material itself is harder to produce, and precision manufacturing adds cost.

However, the initial price is only one part of the full calculation. If a cheaper seal fails quickly, the total cost ends up higher due to repairs and lost production time.

Service Life and Durability

The main advantage of tungsten carbide seal rings is their long service life. They resist:

Wear from friction

Thermal stress from high temperatures

Corrosion from chemicals and seawater

Mechanical shock from sudden pressure changes

In power plants and marine pumps, these properties allow rings to last much longer than steel or ceramic alternatives.

Longer service life reduces replacement frequency and overall cost.

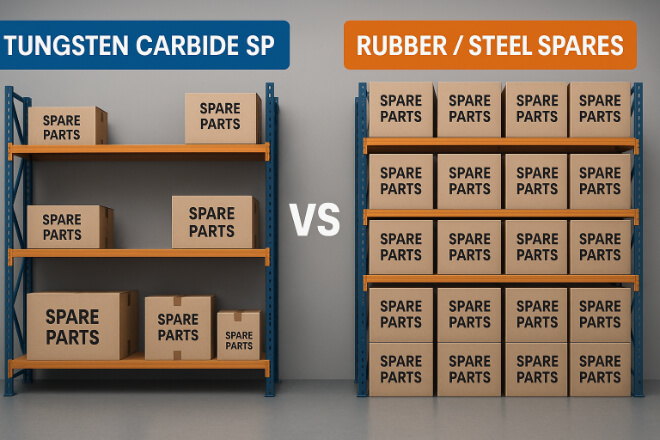

Maintenance Costs

Properly maintained, tungsten carbide seal rings require fewer interventions.

Their wear resistance means fewer inspections and less emergency repair. Companies save money by:

Reducing spare parts inventory

Lowering labor hours for maintenance

Avoiding emergency shutdowns

This makes tungsten carbide more cost-effective in daily operations.

Downtime and Productivity Loss

When a seal ring fails, the cost is not just repair—it is also lost production. In oil and gas, a single hour of downtime can cost thousands of dollars.

Because tungsten carbide seal rings last longer and resist harsh conditions, they reduce unexpected failures. This translates to:

Fewer unplanned shutdowns

Higher production efficiency

Better equipment reliability

This factor often outweighs the higher upfront cost.

Replacement and Inventory Costs

Frequent replacement of seals leads to higher inventory and logistics costs.

With tungsten carbide’s long life, companies need to stock fewer spare parts. This reduces:

Storage costs

Procurement cycles

Shipping costs

Over years, this adds significant savings.

Recycling and Sustainability Value

Unlike rubber seals, tungsten carbide seal rings can be recycled.

Many suppliers offer buy-back or recycling programs. Worn rings are collected, reprocessed, and reused in new components.

This not only reduces disposal costs but also supports sustainability goals, which is increasingly important for global industries.

Comparison with Other Seal Materials

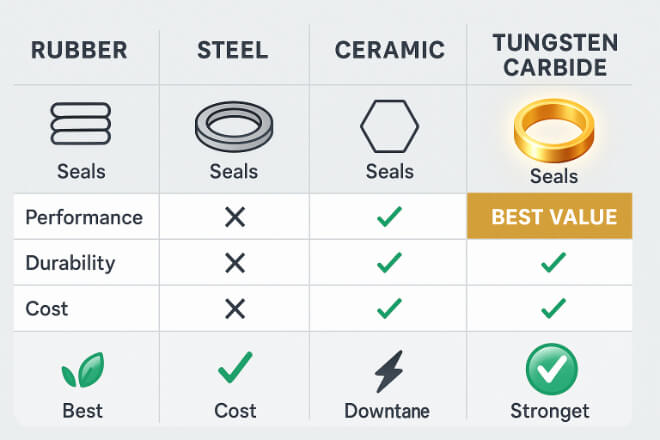

When comparing life cycle costs:

Rubber seals → Cheap, but wear fast, poor under heat/pressure.

Steel seals → Strong but corrode quickly, shorter service life.

Ceramic seals → Hard but brittle, fail under shock loads.

Tungsten carbide seals → Higher cost upfront, but far lower replacement and downtime costs.

The full analysis shows tungsten carbide is the most cost-effective choice over time.

Key Takeaways for Decision-Makers

For managers and engineers, the message is clear:

Tungsten carbide seal rings reduce life cycle cost.

Longer service life means fewer replacements.

Less downtime increases productivity.

Recycling adds extra value and sustainability.

In industries where downtime is extremely expensive, the long-term value of tungsten carbide makes it the smart investment.

Conclusion

A life cycle cost analysis shows that while tungsten carbide seal rings are more expensive to purchase, they are cheaper to own in the long run.

With durability, low maintenance needs, fewer failures, and recyclability, they deliver higher return on investment.

For decision-makers in power generation, marine, chemical, and oil and gas industries, tungsten carbide seal rings are not just a technical choice—they are a financial strategy for efficiency and reliability.

If you want to know more details about any company, please feel free to contact us.