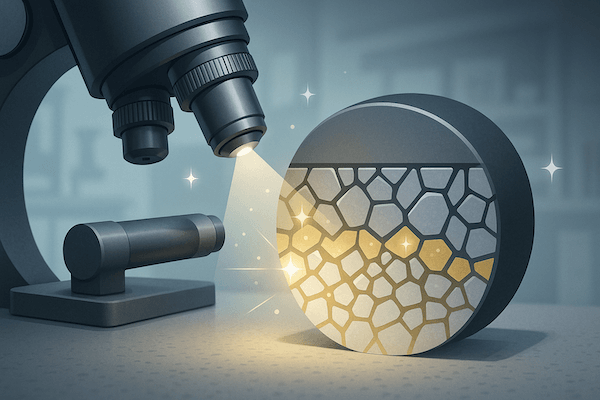

Microstructure analysis is a key technique in materials science that enables the in-depth study of internal structures in metals and composites. For tungsten carbide tools—which are widely used in cutting, mining, wear-resistant, and precision applications—microstructure analysis plays a central role in quality control, performance optimization, and failure prevention.

What Is Microstructure Analysis?

Microstructure analysis refers to the examination of the internal structure of a material at the microscopic level, typically using optical microscopy, scanning electron microscopy (SEM), or even advanced techniques like electron backscatter diffraction (EBSD).

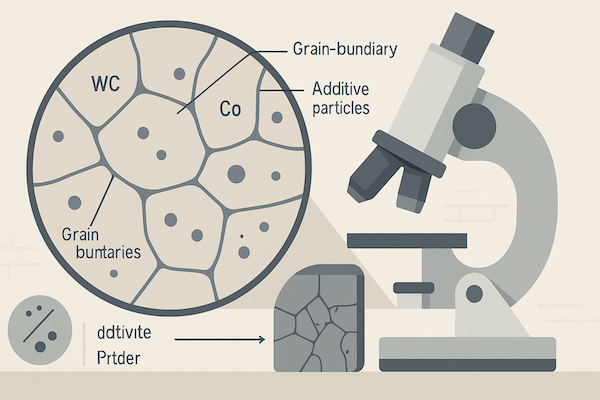

In tungsten carbide (WC)-based materials, microstructure analysis reveals:

WC grain size and morphology

Distribution of the metallic binder phase (usually cobalt or nickel)

Presence of secondary phases (e.g., eta phase, free carbon, or Cr₃C₂ additives)

Porosity and defects

These features are not visible to the naked eye but have a profound effect on tool performance and longevity.

Why Microstructure Matters in Carbide Tooling

1. Performance Optimization

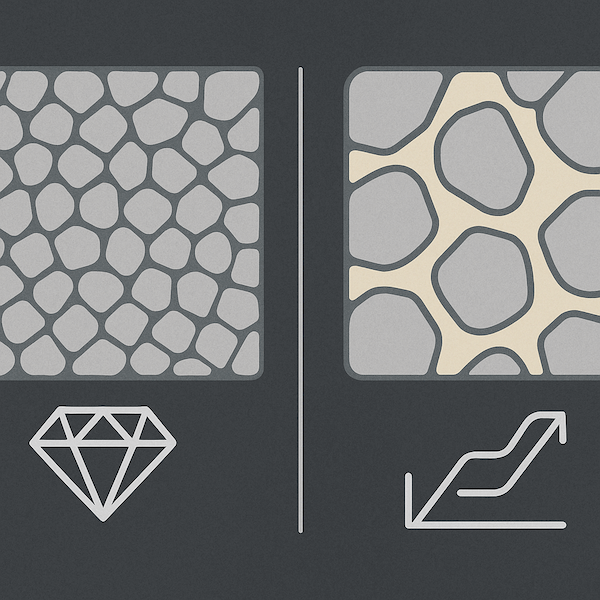

The hardness, toughness, and wear resistance of tungsten carbide tools are directly influenced by microstructure. Key parameters include:

Grain size: Smaller grains provide higher hardness, while larger grains offer more toughness.

Binder content: Affects impact resistance and structural strength.

Grain shape: Irregular shapes may indicate abnormal sintering or deformation.

By analyzing these attributes, engineers can tailor the material to specific applications—whether it’s high-speed cutting or heavy-impact drilling.

2. Quality Control

During manufacturing, microstructure analysis ensures:

Consistent material quality across batches

Detection of abnormal structures (e.g., graphite islands or binder pooling)

Verification of sintering success and densification

Carbide manufacturers often perform microstructure analysis as part of ISO or ASTM standard checks to certify carbide tools for aerospace, medical, and industrial use.

3. Failure Analysis

When a carbide tool fails unexpectedly, microstructure inspection can identify:

Grain boundary decohesion

Binder leaching or erosion

Thermal fatigue or oxidation damage

Microcrack initiation zones

This helps in refining production parameters or user application methods to prevent future issues.

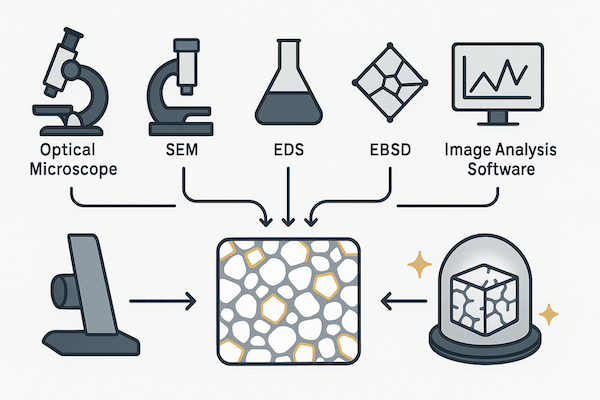

Common Techniques Used in Microstructure Analysis

| Technique | Purpose |

|---|---|

| Optical Microscopy | Basic grain size and porosity analysis (etched samples) |

| Scanning Electron Microscopy | High-resolution surface and fracture analysis |

| Image Analysis Software | Quantitative measurement of grain size distribution |

| EDX/EDS Analysis | Elemental mapping (binder phase, carbide phase) |

| EBSD | Crystallographic orientation and phase identification |

Each of these methods provides insight into different aspects of carbide tool structure and performance.

Standards and Guidelines

Industry standards such as ISO 4499 and ASTM B657 define:

Microstructural classification methods

Etching procedures

Image grading and documentation requirements

Following these standards ensures global consistency and comparability in carbide tool manufacturing and certification.

Conclusion

Microstructure analysis is far more than a lab procedure—it is a vital part of designing, producing, and maintaining high-performance tungsten carbide tools. It links material science with real-world performance, helping manufacturers improve consistency, reduce failure rates, and innovate with confidence. As carbide tools continue to evolve in advanced industries, the role of microstructure analysis will remain foundational to their success.