When designing mechanical systems, non-magnetic materials are often a critical consideration.

Whether in industries like electronics, medical equipment, or mining, certain applications require bushings that do not interfere with magnetic fields.

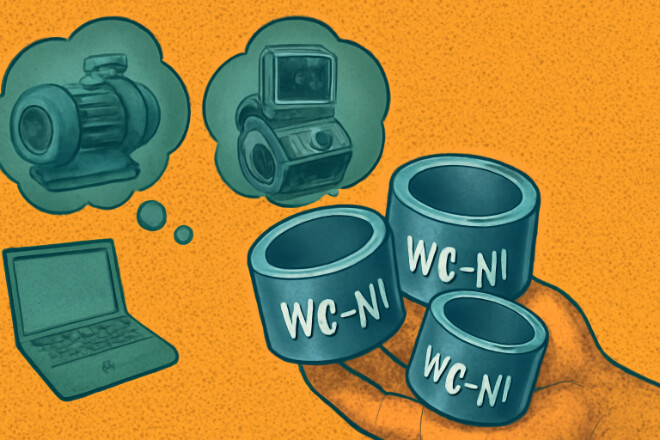

In such cases, WC-Ni (Tungsten Carbide-Nickel) bushings become a key material choice. These bushings provide the strength and wear resistance of tungsten carbide while being non-magnetic, making them ideal for specific applications.

This article will explore the situations when WC-Ni bushings are preferred, the benefits they offer, and how to select them for your application.

What Are WC-Ni Bushings?

WC-Ni bushings are made by combining tungsten carbide (WC) with a nickel (Ni) binder.

Tungsten carbide, known for its exceptional hardness and wear resistance, is often used in mechanical applications where durability is required.

By using nickel as a binder, WC-Ni bushings offer the benefits of tungsten carbide while maintaining a non-magnetic profile, as nickel does not possess magnetic properties in the same way that cobalt-based binders do.

Why Choose WC-Ni Bushings?

Non-Magnetic Properties: Unlike WC-Co (tungsten carbide-cobalt) bushings, WC-Ni bushings are non-magnetic, making them ideal for environments where magnetic interference can cause issues.

Wear Resistance: Tungsten carbide provides outstanding wear resistance, making these bushings suitable for applications with heavy mechanical stress.

Corrosion Resistance: The nickel binder improves corrosion resistance compared to other binder materials, especially in some chemical environments.

Non-Magnetic Requirements in Various Applications

Certain industries require non-magnetic materials due to the potential interference with sensitive equipment, systems, or processes. WC-Ni bushings are designed to meet these needs in several applications.

Key Industries Requiring Non-Magnetic Bushings:

Many devices rely on precise magnetic fields, and magnetic interference can disrupt their functionality.

WC-Ni bushings are used in parts that interact with sensitive equipment like hard drives, sensors, or communication systems.

Medical Equipment:

In medical devices, such as MRI machines, non-magnetic materials are crucial to avoid disrupting the imaging process.

WC-Ni bushings are often used in critical components like motors and bearings in medical applications.

In environments where magnetic fields could interfere with instruments and sensors, non-magnetic WC-Ni bushings are ideal.

They help maintain performance while withstanding abrasive conditions and corrosive elements in mining and oil extraction operations.

Advantages of WC-Ni Bushings

WC-Ni bushings offer several advantages that make them the material of choice for applications requiring non-magnetic properties.

Benefits of WC-Ni Bushings:

Non-Magnetic: WC-Ni bushings are ideal for applications where magnetic interference can cause system errors, such as in medical, aerospace, and electronic devices.

Enhanced Durability: The tungsten carbide content provides the hardness and wear resistance needed to operate in abrasive environments, extending the lifespan of the bushings.

High Temperature Resistance: WC-Ni bushings can perform well in high-temperature applications, making them suitable for heavy-duty equipment like pumps and compressors.

Corrosion Resistance: The nickel binder helps protect the tungsten carbide from certain corrosive environments, which is especially important in chemical processing industries.

When Should You Choose WC-Ni Bushings?

The decision to choose WC-Ni bushings depends on several factors, particularly the specific requirements of your application.

Consider WC-Ni Bushings When:

Magnetic Interference Is a Concern: If your system operates in an environment where magnetic fields can affect performance, WC-Ni bushings are a non-magnetic alternative to cobalt-based bushings.

High Wear Resistance Is Needed: If the system is subject to heavy friction and wear, WC-Ni bushings can provide the durability and longevity needed without compromising performance.

Corrosion Resistance Is Important: In industries like chemical processing, where bushings may be exposed to corrosive fluids, WC-Ni bushings provide better resistance to corrosion than other materials.

High-Temperature Environments: If your application involves elevated temperatures, WC-Ni bushings are capable of withstanding high heat while maintaining performance.

How to Select WC-Ni Bushings for Your Application

Selecting the right WC-Ni bushing involves considering the material’s properties in relation to the specific needs of your application. Here are some tips for choosing the right WC-Ni bushings:

Key Considerations:

Operating Environment: Evaluate the temperature, pressure, and chemical exposure the bushing will experience. WC-Ni bushings are ideal for high wear and moderate temperature conditions.

Magnetic Sensitivity: Ensure that the application truly requires non-magnetic materials. If magnetic interference is a concern, WC-Ni is a strong choice.

Size and Fit: Determine the appropriate size and tolerance for the bushing. WC-Ni bushings should be manufactured to meet the specific dimensions required for your system.

Cost vs. Performance: While WC-Ni bushings are highly durable, they may be more expensive than other materials. Balance performance needs with budget constraints.

Best Practices for Installing WC-Ni Bushings

Proper installation is critical to ensuring that WC-Ni bushings perform optimally throughout their lifecycle. Improper installation can lead to misalignment, wear, and premature failure.

Best Practices for Installation:

Gentle Handling: WC-Ni bushings, though durable, should be handled with care to avoid chipping or cracking, especially when they are thin-walled.

Proper Press-Fit: When installing WC-Ni bushings into a housing or shaft, ensure that the press-fit is evenly applied to prevent stress concentration at the edges.

Use Lubrication: When installing bushings in high-friction areas, use appropriate lubricants to reduce installation forces and ensure a smooth fit.

Avoid Excessive Force: Applying too much force during installation can damage the bushing. Follow manufacturer guidelines for installation methods and torque specifications.

Conclusion

WC-Ni bushings offer a non-magnetic solution for industries requiring high wear resistance and durability in challenging environments.

By selecting the appropriate WC-Ni bushings for applications where magnetic interference is a concern, and ensuring proper installation, you can improve the reliability and lifespan of your systems.

Their combination of non-magnetic properties, wear resistance, and corrosion resistance makes them an excellent choice for electronic, medical, and heavy-duty industrial applications.

If you want to know more details about any company, please feel free to contact us.