Tungsten Carbide Tools for Oil & Gas Industry

From deepwater platforms to high-pressure fracking wells, oil and gas operations demand tools that resist wear, erosion, and extreme temperatures. Retop’s tungsten carbide components are engineered for unmatched performance and durability—custom-made to meet your exact application needs.

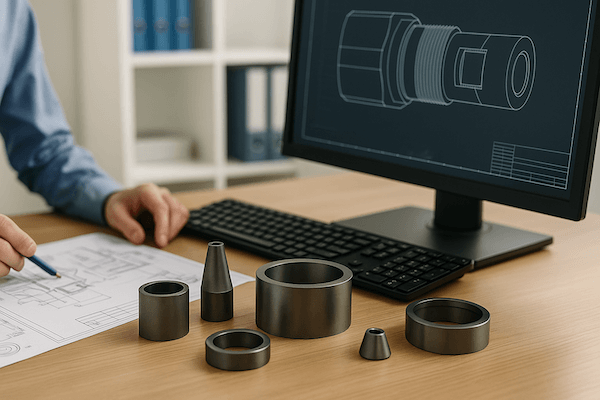

Types Of Oil And Natural Gas Tungsten Carbide Wear Parts

Explore our specialized range of tungsten carbide wear parts designed for the toughest oilfield operations, including drilling, pumping, flow control, and sealing applications.

Quick and easy: Enter your specifications and get a quote in one business day

Oil & Gas Application Scenarios for Tungsten Carbide Parts

Explore the critical environments where Retop’s tungsten carbide components deliver precision, strength, and reliability—from offshore platforms to deep well drilling and pipeline flow control.

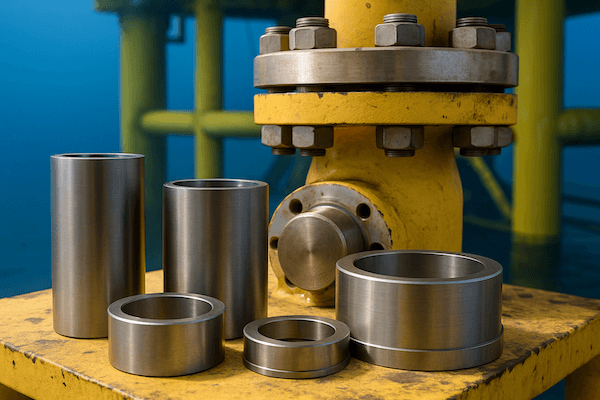

Offshore Platforms

Carbide trim components, seal rings, and wear sleeves ensure valve durability in subsea production units.

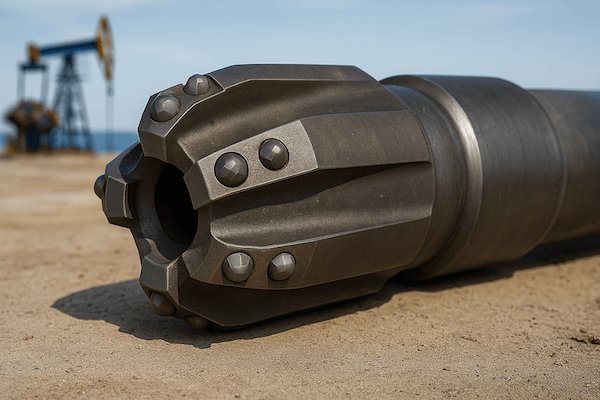

Downhole Drilling

Tungsten carbide inserts and sleeves provide impact and erosion resistance in MWD/LWD and drilling assemblies.

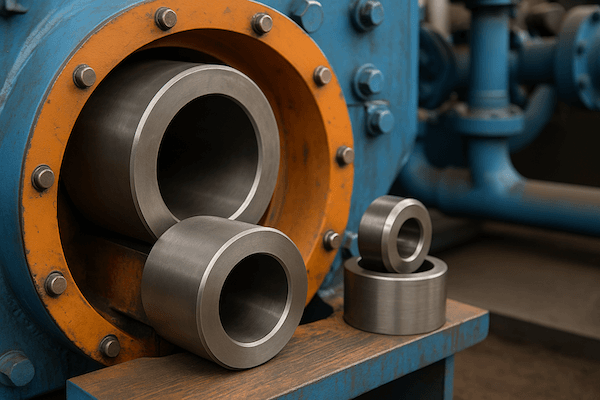

Mud Pumps

Carbide nozzles and liners protect critical mud pump paths against abrasive slurry wear in high-volume operations.

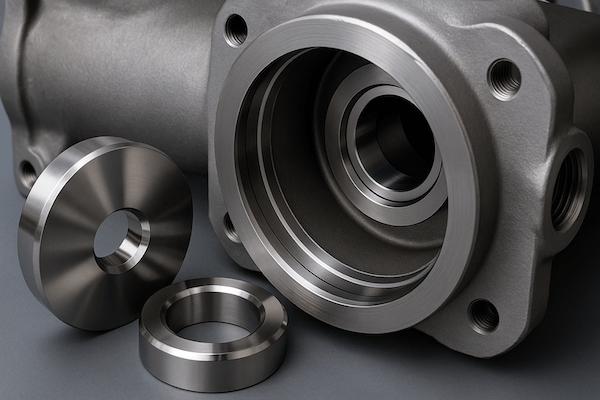

Oil Pipeline Valves

Flow control orifices and seal rings ensure leak-free, precision oil flow in high-pressure valve systems.

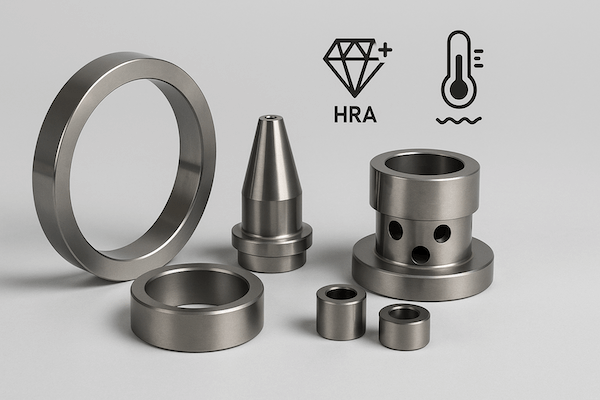

Technical Advantages of Tungsten Carbide Tools

Our tungsten carbide tools offer exceptional mechanical and thermal performance for oil and gas drilling, pumping, and sealing—ensuring maximum uptime in corrosive and high-pressure conditions.

Carbide Dressing Rollers

| Feature | Benefit |

|---|---|

| HRA Hardness up to 92+ | Outstanding wear protection |

| Corrosion & Acid Resistance | Works in H₂S and brine environments |

| Custom Grades (e.g., YG15, YG20C) | Matched to specific operating conditions |

| Precision Machining | Tolerances to ±0.01 mm |

| Surface Finish Options | Lapped, honed, or coated as needed |

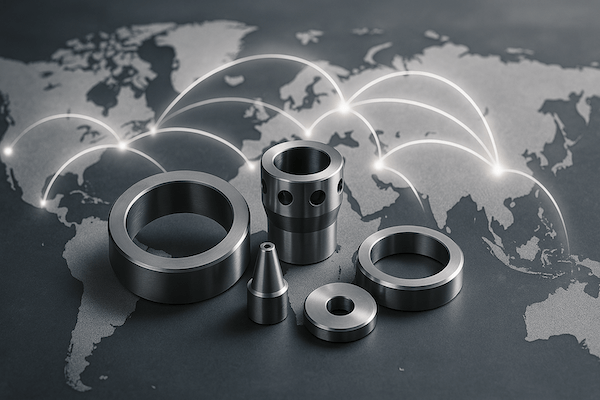

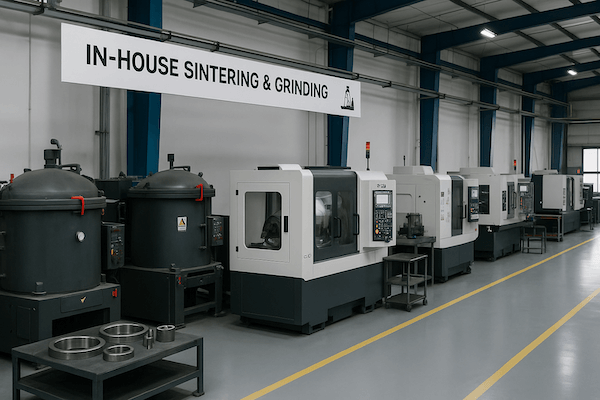

Trusted Tungsten Carbide Partner for Oilfield Components

Retop combines 14 years of production experience with global delivery and full customization support.

FAQ

Get answers to common questions about tungsten carbide components used in the oil and gas industry, including tolerances, customization, standards, prototyping, and delivery schedules.

Can you supply tungsten carbide parts that meet API or NACE standards?

Yes, we offer custom grades specifically for sour gas and high-pressure applications.

Do you support small batch or prototyping orders?

Yes, Retop supports flexible batch sizes including samples for new project development.

What tolerances can you achieve on carbide parts?

We offer precision machining up to ±0.01 mm depending on geometry and size.

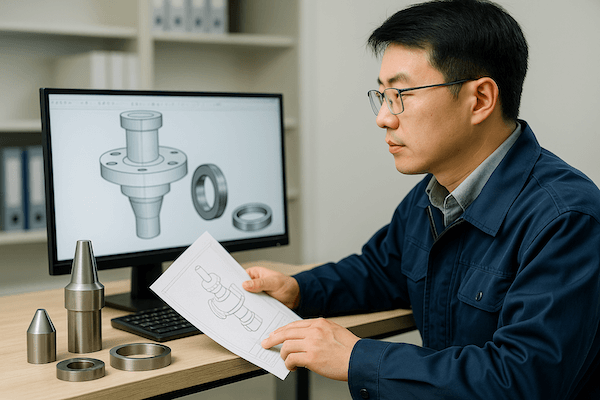

Can I request drawings or 3D models before production?

Yes, we provide 2D/3D models for approval before toolmaking.

What surface finish options do you offer?

We can provide lapped, ground, polished, or coated surfaces based on functional needs.

What is your lead time for carbide oilfield parts?

Lead times typically range from 15 to 25 days depending on complexity and quantity.

Quick and easy: Enter your specifications and get a quote in one business day