Precision measurement is a cornerstone of modern manufacturing, especially in the production and quality control of tungsten carbide tools. As one of the hardest and most wear-resistant materials, tungsten carbide (WC) is used in industries where tight tolerances, dimensional accuracy, and surface integrity are non-negotiable. In this article, we explore what precision measurement is, why it’s crucial in the carbide tooling industry, and what methods are used to ensure optimal performance.

What Is Precision Measurement?

Precision measurement refers to the use of high-accuracy instruments and methods to determine the exact dimensions, geometry, surface finish, and tolerances of a component. In the case of tungsten carbide tools, even tiny deviations in measurement—on the scale of microns—can affect tool fit, cutting performance, wear resistance, and service life.

Precision measurement is applied throughout the carbide tool lifecycle:

During production (to verify geometry and grinding quality)

In quality control (to certify tolerances and material specs)

For tool reconditioning and failure analysis

Why Precision Measurement Matters for Carbide Tools

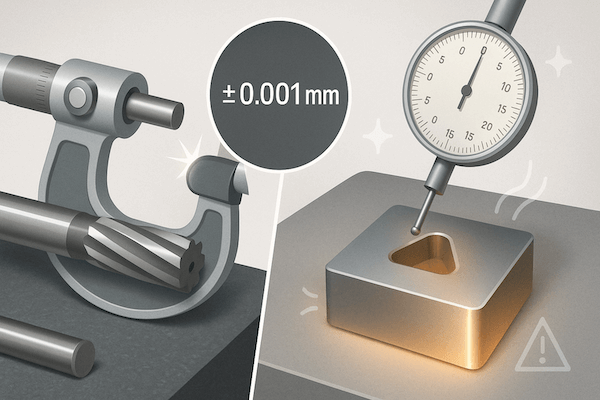

1. Tight Tolerances

Tungsten carbide tools are often used in applications such as metal cutting, mold making, and electronics manufacturing, where tolerances as tight as ±0.001 mm are required. Precision measurement ensures tools meet:

Dimensional specifications (e.g., diameter, thickness, taper)

Concentricity and symmetry

Form and position tolerances

2. Tool Performance and Wear Monitoring

Regular inspection of tool wear using precise measurement techniques helps:

Predict tool life

Prevent sudden failure during operation

Optimize replacement schedules

This is especially critical in automated CNC machining or high-speed production lines.

3. Quality Assurance and Certification

Precision measurement is essential for:

Ensuring compliance with international standards (ISO, DIN, ANSI)

Delivering inspection reports to customers

Verifying custom or complex geometries in special-grade carbide inserts or cutting edges

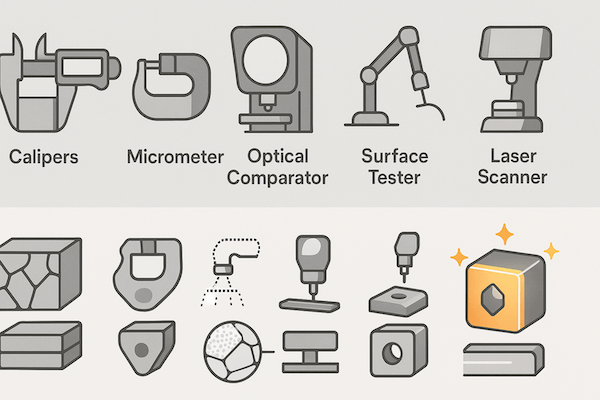

Common Precision Measurement Tools Used for Carbide

| Instrument | Purpose |

|---|---|

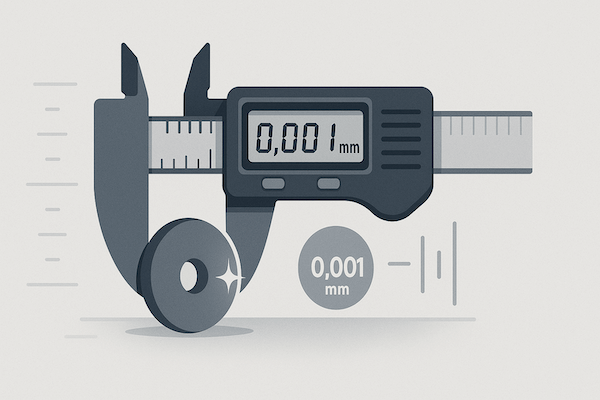

| Digital Calipers | General dimensions (±0.01 mm) |

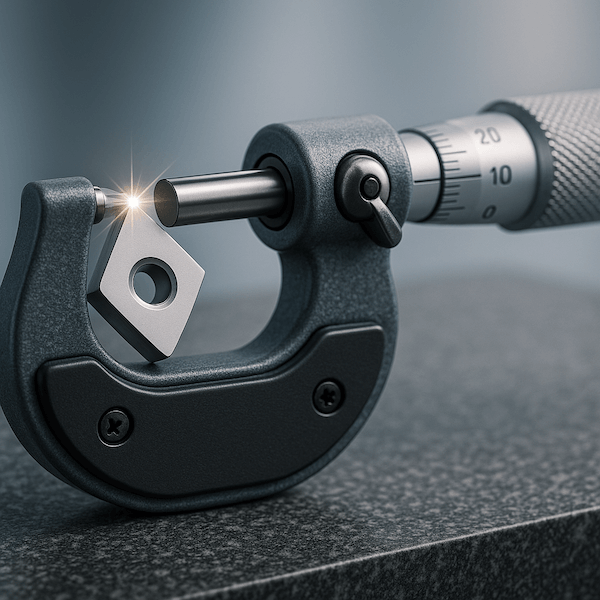

| Micrometers | Outer/inner diameter (±0.001 mm) |

| Profile Projectors (Optical Comparator) | Shape, radius, angle inspection |

| CMM (Coordinate Measuring Machine) | 3D form and positional accuracy |

| Surface Roughness Testers | Surface finish in Ra, Rz (µm) |

| Laser Scanners / Vision Systems | Non-contact inspection of small tools |

Each method plays a role in maintaining consistency across production batches.

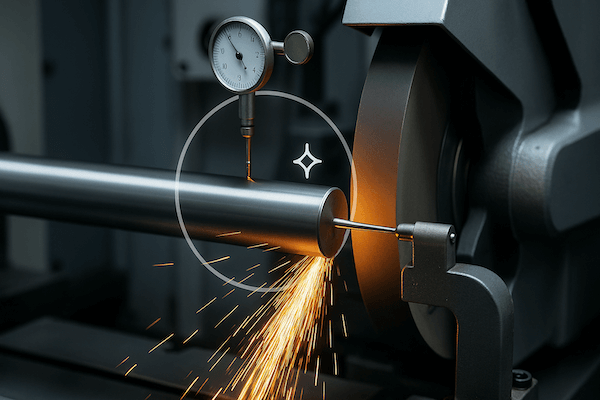

Precision in Carbide Manufacturing Processes

High-precision grinding, EDM (Electrical Discharge Machining), and polishing techniques used in carbide tooling demand equally precise metrology. For example:

Carbide end mills and reamers require concentricity checks under 5 µm.

Carbide nozzles or dies must maintain micro-tolerances across the flow path.

Mirror-polished carbide seal faces are measured for flatness using interferometers.

In many facilities, measurement is integrated into automated production cells for real-time quality assurance.

Conclusion

Precision measurement is not just a quality checkpoint—it is a core enabler of performance, durability, and global competitiveness in the tungsten carbide tooling industry. With the increasing demand for complex geometries, ultra-fine tolerances, and fast turnaround times, investing in precision metrology is essential for any manufacturer or end-user relying on carbide tools. From digital micrometers to CMMs, the right tools ensure every part performs as designed—down to the micron.