Tungsten carbide bushings are vital components in various industrial applications, known for their exceptional durability, wear resistance, and hardness.

These properties make them ideal for use in high-load, high-speed environments. However, proper handling and storage are essential to maintain the integrity and performance of tungsten carbide bushings.

Mishandling or improper storage can lead to cracks, chips, or other forms of damage that may affect the bushing’s performance and lifespan.

In this blog, we’ll explore best practices for handling and storing tungsten carbide bushings to ensure they operate at peak efficiency.

Why Proper Handling Matters for Tungsten Carbide Bushings

Tungsten carbide is a hard and brittle material, which means it is susceptible to damage if not handled correctly.

While it can withstand extreme conditions during operation, improper handling can lead to cracks or chips that compromise the bushing’s performance.

1). Potential Risks of Poor Handling:

Cracking and Chipping: Dropping or mishandling tungsten carbide bushings can cause them to crack or chip. These imperfections can lead to early failure.

Deformation: Bending or applying excessive force to tungsten carbide can deform the bushing, affecting its fit and performance.

Surface Damage: Scratches or other surface imperfections can increase friction and wear, reducing the bushing’s effectiveness.

2). Best Practices for Handling:

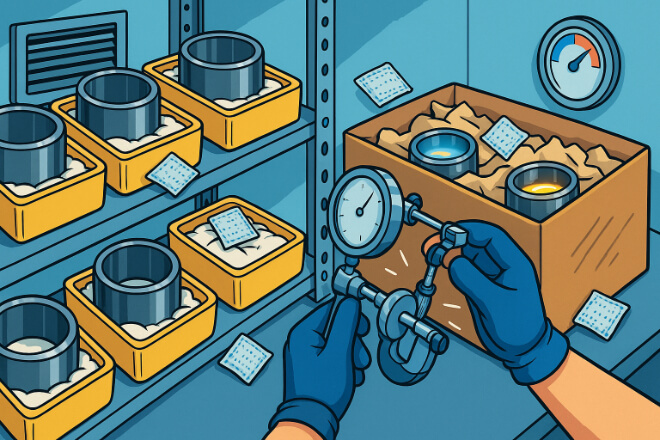

Wear Protective Gear: Always wear gloves when handling tungsten carbide bushings to protect them from direct impact and contamination.

Use Proper Tools: Utilize lifting and installation tools, such as clamps or hoists, to handle bushings carefully, especially for larger sizes.

Avoid Dropping: Store and transport bushings in padded or cushioned containers to prevent accidental drops.

How to Store Tungsten Carbide Bushings

Storing tungsten carbide bushings correctly is just as important as handling them properly.

Incorrect storage can lead to corrosion, contamination, and even cracking, all of which can affect the bushing’s longevity and functionality.

1). Key Factors Affecting Storage:

Moisture: Exposure to moisture can lead to corrosion and rust on the surface of the bushing, which can impair its performance.

Temperature: Extreme temperature fluctuations can cause thermal expansion or contraction of the bushing material, leading to cracking or warping.

Contamination: Storing tungsten carbide bushings in areas with dust, dirt, or chemical exposure can lead to surface contamination and wear.

2). Best Practices for Storage:

Store in Dry Conditions: Ensure the storage area is dry and free from moisture. Use silica gel packs or desiccants to absorb any humidity in the storage container.

Temperature Control: Store the bushings in a climate-controlled environment to prevent any thermal stresses caused by extreme temperatures.

Use Protective Packaging: Place the bushings in protective packaging such as foam, rubber, or plastic to prevent direct contact with abrasive surfaces or harsh chemicals.

Handling and Storing Tungsten Carbide Bushings During Transportation

Transportation poses another risk to tungsten carbide bushings, particularly when they are being moved between locations for installation or repairs.

The handling and storage methods used during transportation can affect the bushing’s integrity.

Best Practices During Transportation:

Cushioning: Ensure that the bushings are properly cushioned to prevent damage during transportation. Use foam padding, bubble wrap, or soft bags to protect the bushings from impact.

Secure Packaging: Pack bushings securely in crates or boxes to prevent shifting during transport. This will reduce the risk of contact with hard surfaces or other materials that may cause damage.

Labeling: Clearly label containers with information about the contents, such as “fragile” or “handle with care,” to ensure that the bushings are handled properly during transport.

Best Practices for Installation of Tungsten Carbide Bushings

The installation process is another critical factor that can affect the performance of tungsten carbide bushings.

Even with proper storage and handling, incorrect installation can lead to improper fit, misalignment, and excessive wear.

Tips for Safe Installation:

Check Dimensions: Always verify that the dimensions of the bushing match the required specifications for the shaft and housing.

Align Correctly: Use alignment tools to ensure the bushing is aligned properly with the shaft and housing. Misalignment can cause wear and reduce the bushing’s lifespan.

Avoid Using Excessive Force: Apply gentle pressure when installing the bushing to avoid cracking or chipping the material. Use proper installation tools to achieve a smooth fit.

Regular Inspection and Maintenance

Even with proper handling, storage, and installation, regular inspection and maintenance are essential to ensure the bushing continues to perform optimally.

Inspecting the bushing for signs of wear or damage can help catch issues early before they lead to costly failures.

1). What to Inspect:

Wear and Tear: Look for signs of excessive wear, such as grooves, cracks, or thinning in the bushing material. These are signs that the bushing may need to be replaced.

Surface Damage: Check for any surface chips, cracks, or pitting that may have occurred during handling or operation.

Lubrication: Ensure that the bushing is properly lubricated, as lack of lubrication can increase friction and wear.

2). Inspection Frequency:

Daily or Weekly: For high-use applications, inspect the bushings daily or weekly for signs of wear.

Monthly or Quarterly: For less frequently used systems, perform a more detailed inspection on a monthly or quarterly basis.

Handling and Storage Best Practices for Tungsten Carbide Bushings

| Best Practice | Reason | Tip |

|---|---|---|

| Store in Dry, Controlled Environment | Prevents corrosion and damage | Use desiccants or silica gel packs to absorb moisture |

| Handle with Care | Minimizes risk of cracks and chips | Wear gloves and use lifting tools to avoid damage |

| Use Proper Packaging During Transport | Prevents physical damage during transit | Cushion bushings with foam or bubble wrap in crates |

| Regular Inspections | Detects early signs of wear or damage | Inspect bushings for cracks, wear, and lubrication |

Conclusion

Proper handling and storage of tungsten carbide bushings are essential for ensuring their longevity and performance.

By following the best practices for handling, storing, and installing these critical components, you can avoid premature wear and costly repairs.

Regular inspections and maintenance will further ensure that your tungsten carbide bushings continue to perform at their best, providing reliable service and reducing downtime.

If you want to know more details about any company, please feel free to contact us.