Quality Assurance

As a leading manufacturer of tungsten carbide tools, we understand that uncompromising quality is the foundation of customer trust and equipment performance. From raw‐material verification to final bench tests, our multi‐stage inspection process ensures every tool meets the highest international standards.

Why Quality Matters

Tungsten carbide tools operate under extreme conditions—high speed, temperature, and pressure.

Any failure in the field can:

Jeopardize operator safety and machine uptime

Generate costly downtime and emergency tool replacements

Damage your reputation in competitive global markets

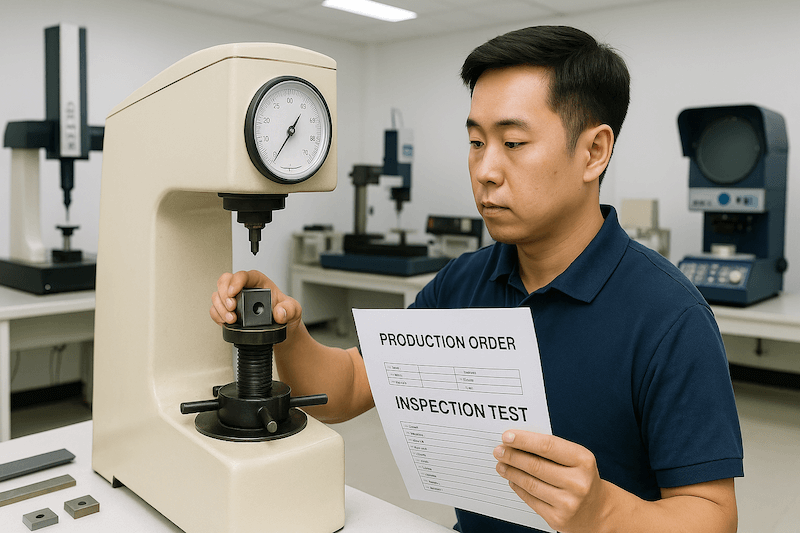

Our Five-Step Inspection Workflow

Each stage is governed by strict pass/fail criteria and documented for full traceability.

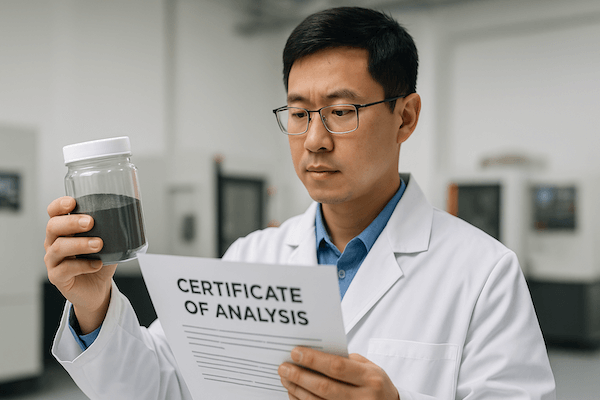

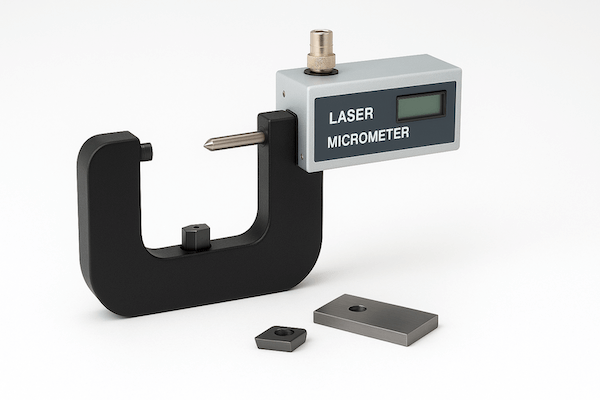

Incoming Materials Verification

Every batch of WC–Co powder undergoes rigorous chemical and physical analysis. Grain size is measured via laser diffraction to ensure uniform distribution (D₅₀ ≤ 1.5 µm). XRF spectrometry confirms cobalt binder content matches specifications (±0.2 wt%). Certificates of analysis and lot numbers are cross-checked for full traceability before production.

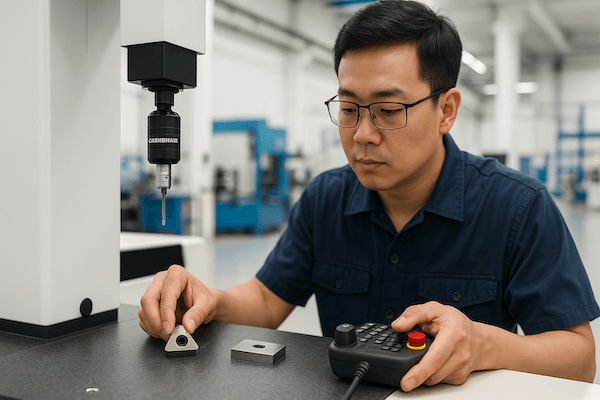

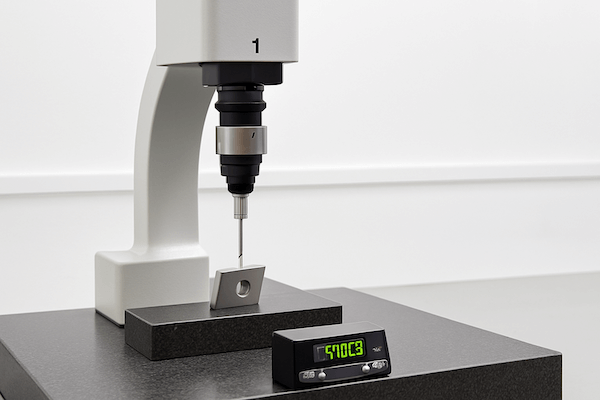

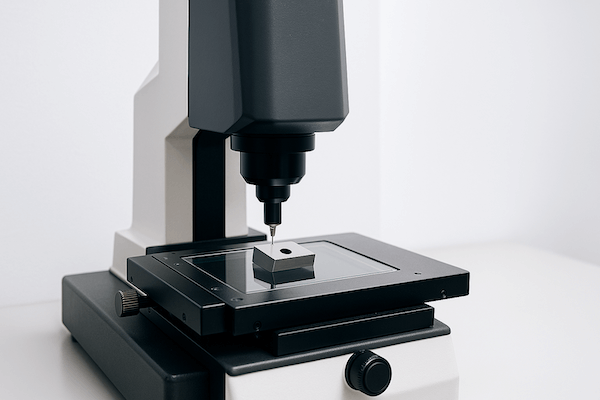

Dimensional & Geometric Checks

Finished tools are measured on a CNC CMM to verify critical tolerances (±0.005 mm). Profile projectors inspect cutting-edge radii and clearance angles at 50x magnification. Roundness, concentricity, and parallelism of shafts and balls are validated to IEC and ISO standards, ensuring seamless integration in high-precision assemblies.

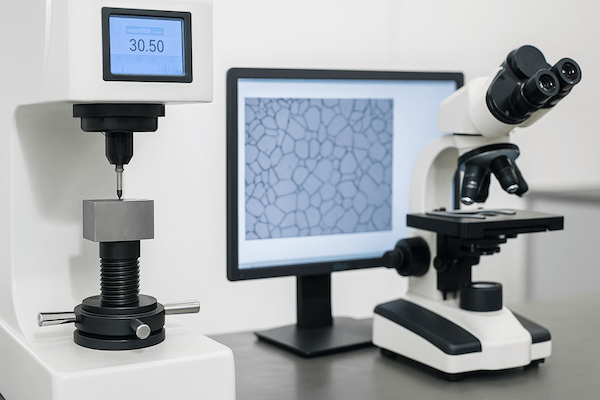

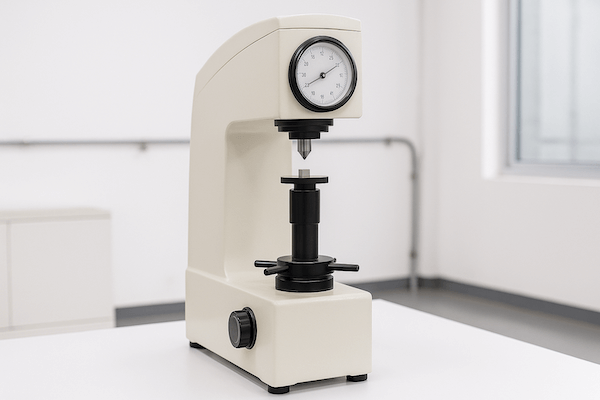

Hardness & Microstructure Testing

Rockwell hardness (HRA/HRC) tests assess binder distribution and substrate strength. Metallographic cross-sections are polished and etched to reveal grain size and porosity under 400x magnification. The microstructure must comply with ASTM B462 criteria—no visible large pores, uniform cobalt network—to guarantee toughness and wear resistance.

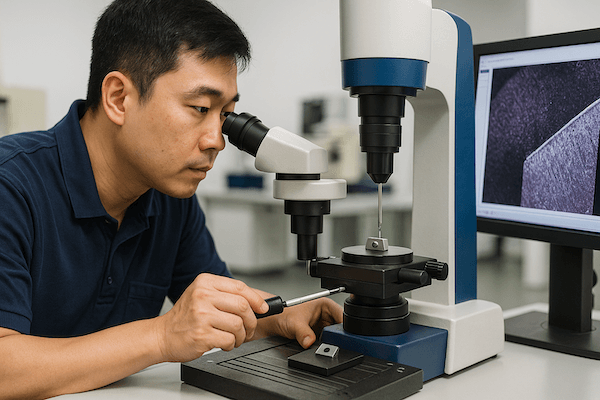

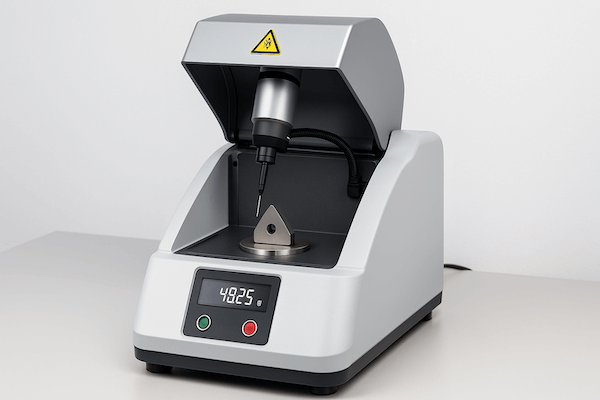

Surface Finish & Coating Inspection

A stylus profilometer measures surface roughness (Ra ≤ 0.1 µm) on cutting edges. Video-microscope checks for micro-chipping and coating defects at 100x magnification. PVD coatings (TiAlN, AlTiN) are thickness-tested (2–4 µm) using magnetic pull-off gauges and adhesion tape tests per ISO FP0510 standards to ensure long tool life.

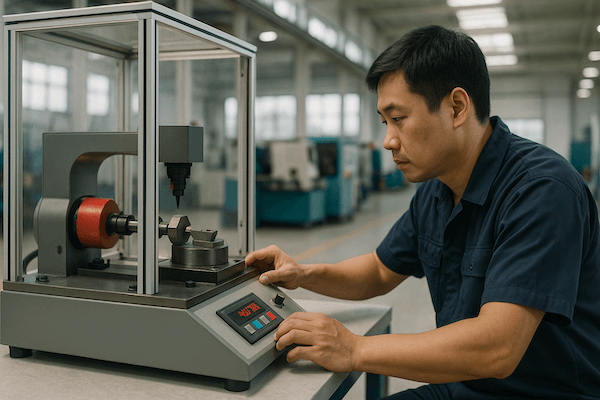

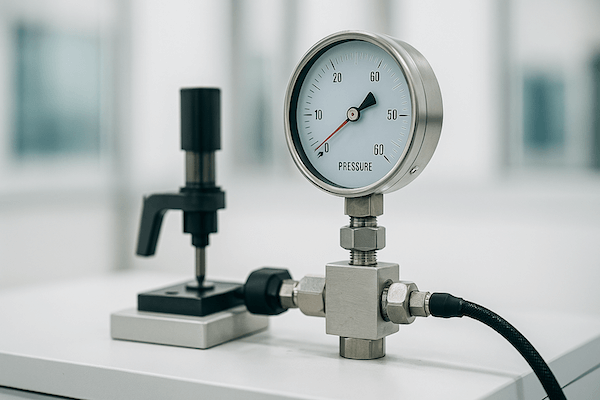

Final Functional Testing

ESimulated bench-tests replicate real-world cutting, measuring wear rates, chipping, and edge retention over defined cycles. Torque and force sensors verify consistent performance under load. Each tool must pass against established endurance benchmarks—e.g., ≤10% flank wear after 1,000 m of cutting—before shipment to guarantee field reliability.

Quick and easy: Enter your specifications and get a quote in one business day

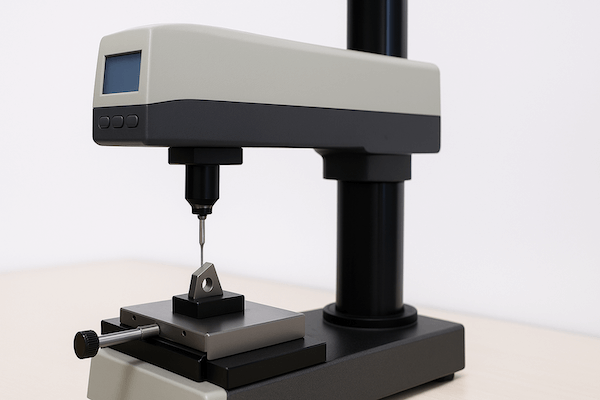

Advanced Testing Equipment

As a leading tungsten carbide tool maker, we use advanced QC equipment ensuring product excellence.

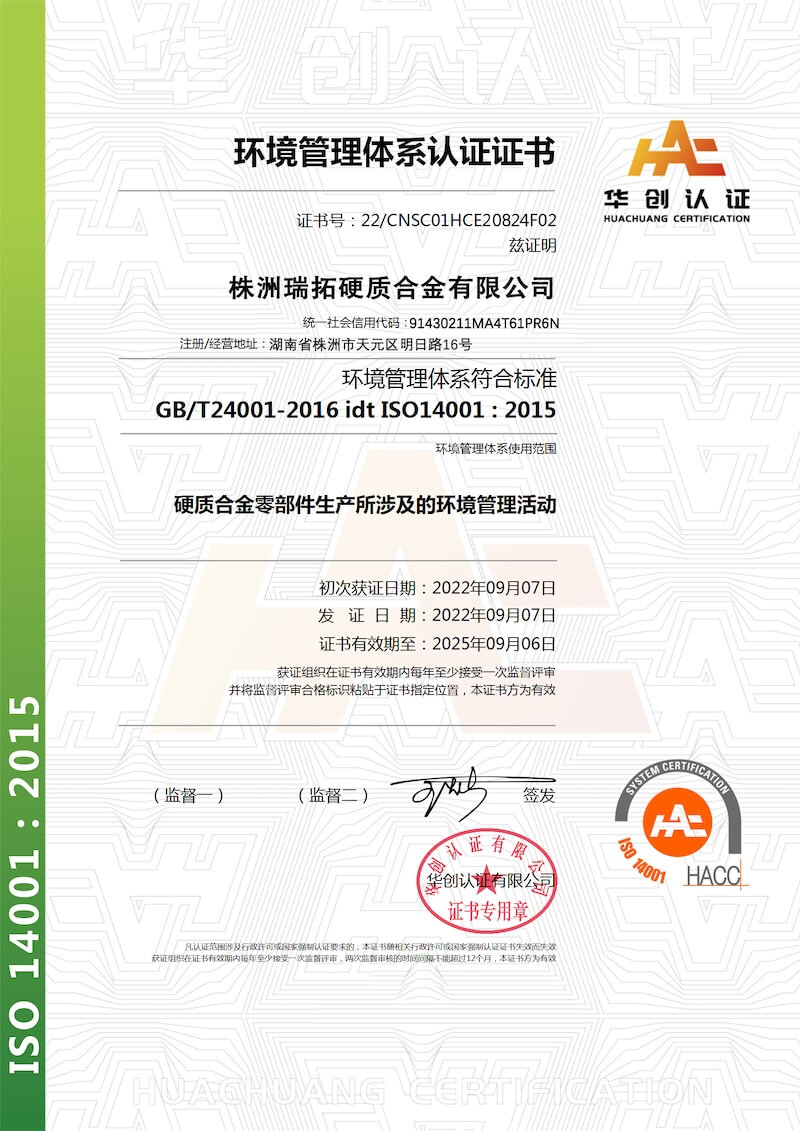

Certificate

Our tungsten carbide tools carry professional structural certifications, guaranteeing validated strength, precision, and industrial reliability.

Conclusion

Our meticulous, multi-stage inspection process—from incoming powder analysis to final functional testing—demonstrates our unwavering commitment to quality. Partner with us for tungsten carbide tools you can trust in the toughest applications.

Quick and easy: Enter your specifications and get a quote in one business day