In industries such as mining, oil and gas, metalworking, and manufacturing, the performance of machines depends on the strength of their wear parts.

These parts face high pressure, heat, and friction, so they must be made from materials that can last in tough environments. Tungsten carbide wear parts are among the most reliable solutions.

But what makes carbide parts so strong? The answer lies in their manufacturing process.

Techniques like sintering, Hot Isostatic Pressing (HIP), and precision fabrication are what give carbide wear parts their extreme hardness, toughness, and long life.

This article explains these processes in simple terms and shows why they are critical for companies that need reliable wear solutions.

What Is Sintering in Carbide Production?

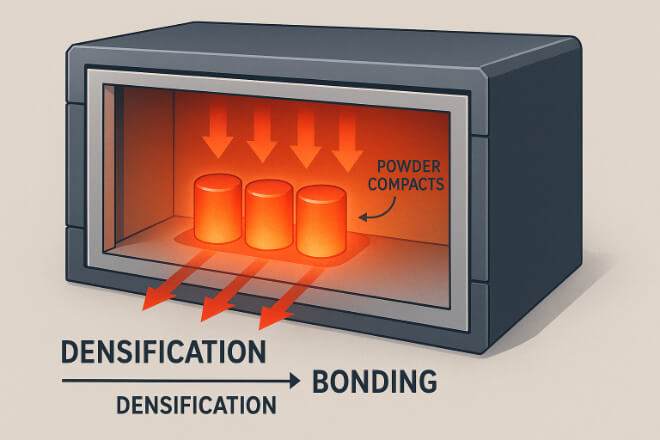

Sintering is the process of heating pressed carbide powder at very high temperatures without melting it completely.

The heat causes the tungsten carbide particles and binder (usually cobalt or nickel) to fuse together into a solid, dense material.

Steps in sintering:

Powder Preparation – Mixing tungsten carbide powder with a binder.

Pressing – Forming the mixture into a compact “green part.”

Heating – Placing the compact into a furnace at temperatures around 1400–1500 °C.

Densification – Particles bond tightly, reducing porosity and increasing strength.

Why sintering matters:

It transforms fragile powder compacts into hard, durable parts.

It gives carbide parts their hardness and wear resistance.

It ensures the right density and microstructure for long service life.

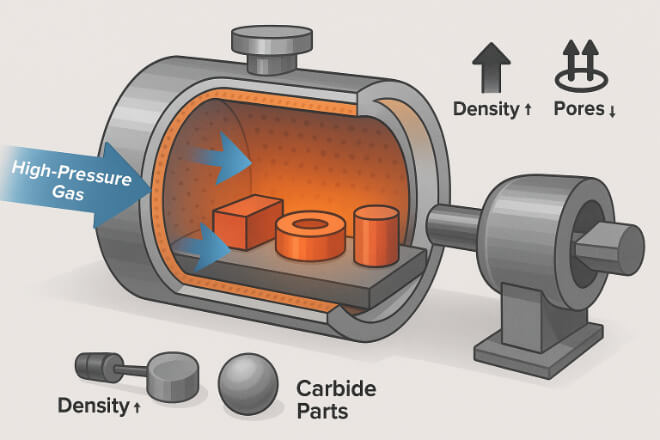

Role of HIP (Hot Isostatic Pressing)

After sintering, some carbide parts undergo Hot Isostatic Pressing (HIP). This process uses high temperature and high gas pressure applied from all directions.

Benefits of HIP:

Removes internal pores that remain after sintering.

Increases density to nearly 100%.

Improves toughness and reliability of carbide parts.

Extends service life, especially in critical applications like oil & gas valves, mining tools, and aerospace components.

HIP is especially important when parts must work under extreme pressure, high stress, or corrosive environments. Decision-makers often prefer HIP-treated parts because they perform better and reduce failure risks.

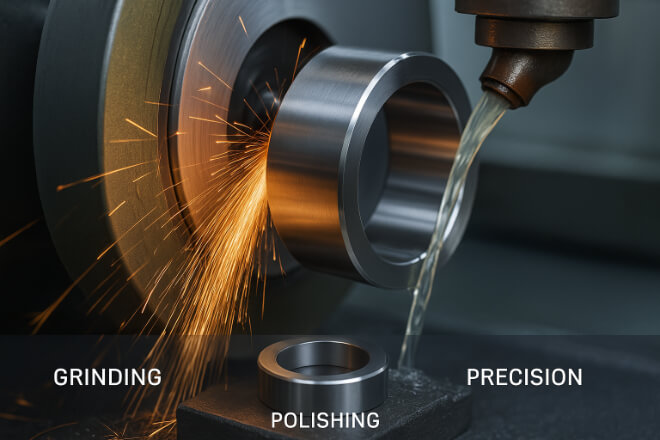

Fabrication and Finishing of Carbide Wear Parts

Once carbide parts are sintered and possibly HIP-treated, they move to the fabrication stage.

Because carbide is extremely hard, special tools and techniques are required.

Key fabrication processes:

Diamond Grinding: Used to shape parts with very high precision.

Lapping and Polishing: Creates ultra-smooth surfaces for seal rings, nozzles, and precision components.

EDM (Electrical Discharge Machining): Used for complex shapes that are hard to grind.

Coating (optional): Applying layers like TiN, TiC, or DLC for extra wear and corrosion resistance.

Fabrication ensures that carbide wear parts not only last long but also fit perfectly into machines, keeping performance consistent and reliable.

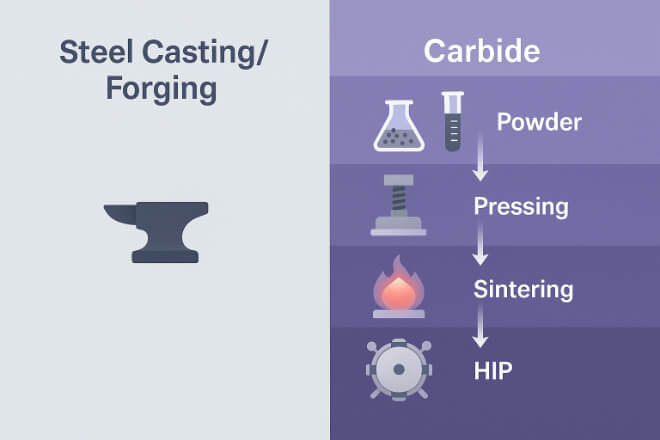

Comparison with Conventional Steel Processing

To understand why carbide needs these advanced processes, it helps to compare with steel:

Steel wear parts: Produced by casting or forging, then machined. Easier to shape, but softer and less durable.

Carbide wear parts: Require pressing, sintering, HIP, and diamond machining. More complex and costly, but far superior in hardness and wear life.

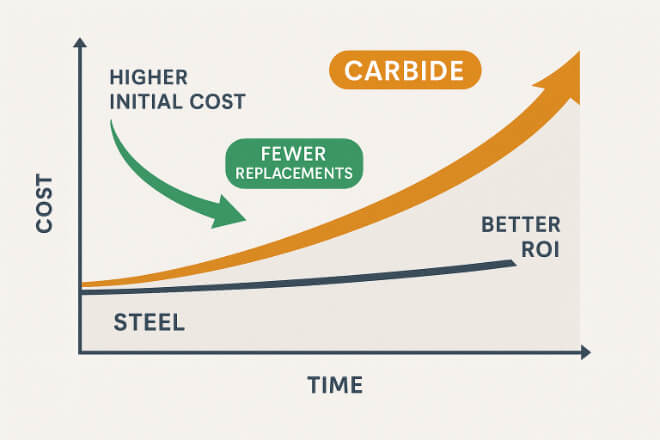

The extra processing steps make carbide parts more expensive upfront, but their durability delivers much better value over time.

Cost and ROI Advantages of Advanced Processing

For decision-makers, the main question is: “Do these advanced processes add value?” The answer is yes.

Fewer Replacements – HIP and sintering give parts higher strength, reducing replacement frequency.

Less Downtime – Machines run longer without interruptions.

Improved Productivity – Precision fabrication ensures smoother operations.

Better ROI – Though initial costs are higher, lifecycle savings are significant.

Investing in carbide wear parts with sintering, HIP, and precise fabrication pays off by lowering overall costs.

Applications of Sintered and HIP-Treated Carbide Parts

Industries that demand high performance rely on these processes:

Mining & Construction: Carbide tips, picks, and inserts resist impact and abrasion.

Oil & Gas: Seal rings, valve parts, and flow control components withstand pressure and corrosion.

Metalworking: Cutting inserts and dies maintain sharpness under high heat.

Wood & Paper: Carbide blades and knives cut cleaner and last longer.

Aerospace & Automotive: Precision parts provide reliability and safety.

Without sintering and HIP, these industries would face higher costs, frequent breakdowns, and reduced efficiency.

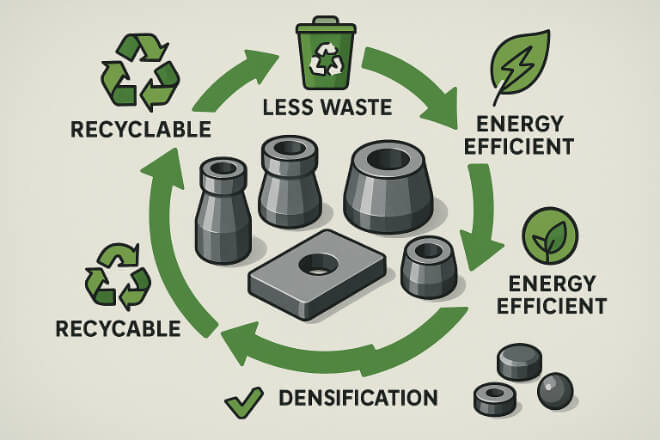

Environmental and Sustainability Benefits

Advanced processing methods also support sustainability:

Recycling: Tungsten carbide can be reclaimed and re-sintered, lowering raw material demand.

Reduced Waste: Longer life means fewer discarded parts.

Energy Efficiency: Machines run more smoothly, consuming less energy.

For companies aiming at both performance and environmental responsibility, carbide wear parts made with sintering and HIP are a strong choice.

Choosing the Right Supplier

Not all carbide parts are equal. Quality depends on proper sintering, HIP, and fabrication methods. When choosing a supplier, decision-makers should look for:

Experience in advanced carbide processing.

Strict quality control and ISO certifications.

Ability to provide custom grades and designs.

Proven success in demanding industries.

The right supplier ensures consistent quality, higher ROI, and long-term reliability.

Conclusion

The strength and cost benefits of carbide wear parts come not just from the material itself but from the advanced processes used in their production.

Sintering, HIP, and precision fabrication are what make carbide parts last longer, perform better, and save money over time.

For industries where downtime is costly and reliability is essential, choosing carbide wear parts with these advanced processes is not just an option—it’s the best strategy.

If you want to know more details about any company, please feel free to contact us.