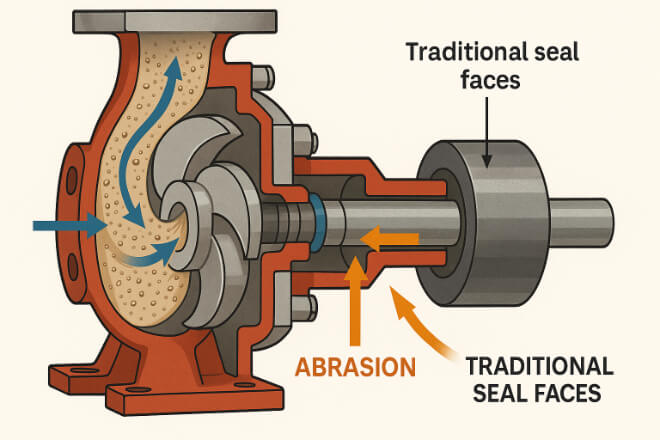

Submersible pumps often operate in extremely harsh water environments—such as wells, mines, construction sites, or irrigation systems—where sand, silt, and suspended particles are unavoidable.

These fine abrasives quickly damage traditional seal materials, leading to leakage, vibration, and premature failure.

To combat this, engineers increasingly rely on carbide seal faces, which are designed to resist abrasion and maintain sealing performance even in sand-laden or dirty water.

This article explains why carbide faces outperform other materials in submersible pump seal stacks.

How they handle abrasion and pressure, and what design factors decision-makers should consider when specifying seals for demanding applications.

The Challenge of Sand-Laden Water

Sand is one of the most aggressive contaminants in water systems.

Its particles are small enough to enter tight clearances yet hard enough to scratch and erode seal surfaces.

Common problems caused by sand in submersible pump seals include:

Face wear that increases leakage.

Groove formation that reduces sealing effectiveness.

Heat buildup due to increased friction.

Shaft misalignment and vibration from uneven wear.

In such abrasive environments, standard seal materials like carbon or ceramic often fail within weeks, making carbide seal faces the preferred solution.

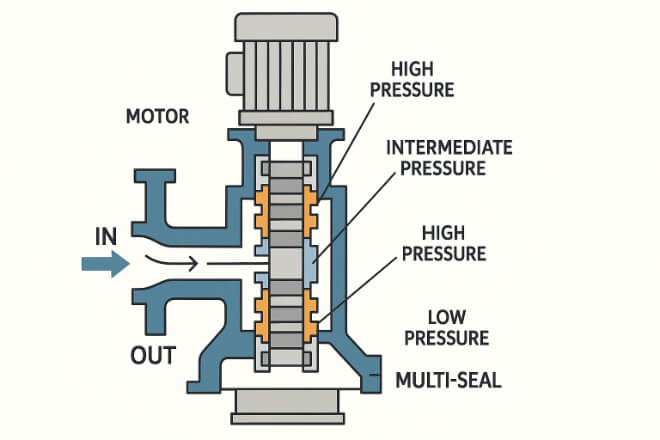

What Is a Seal Stack in Submersible Pumps?

A seal stack is a series of mechanical seals assembled vertically to isolate the motor chamber from the pumped fluid.

The typical configuration includes multiple stages, each handling part of the pressure differential and fluid barrier.

Functions of a Seal Stack

Prevent leakage between pump and motor.

Balance pressure to avoid overload on one stage.

Protect bearings from contamination.

Allow continuous lubrication with clean oil or water film.

Because submersible pumps often run fully submerged, the seal stack must survive constant pressure, abrasive particles, and temperature fluctuations.

Why Carbide Faces Perform Best in Abrasive Environments

Carbide materials—especially tungsten carbide (WC) and silicon carbide (SiC)—are engineered for toughness, wear resistance, and stability.

In sand-laden water, these properties translate directly to longer service life and consistent sealing performance.

1). Superior Hardness

Carbide faces are extremely hard (8.5–9 on the Mohs scale), meaning sand grains cannot easily cut or embed into the surface.

This prevents scoring and keeps sealing surfaces flat.

2). Low Wear Rate

WC faces show minimal volume loss even after extended exposure to slurry conditions. The result is lower leakage and fewer maintenance shutdowns.

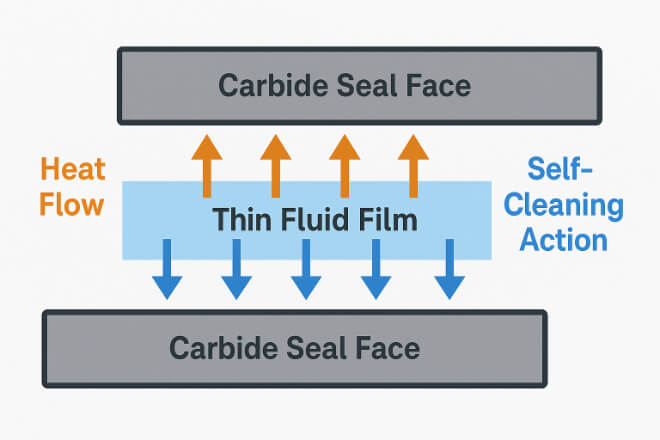

3). High Thermal Conductivity

Carbide efficiently transfers heat away from the contact zone, reducing temperature spikes caused by friction.

This prevents thermal cracking, a common failure mode in softer materials.

4). Structural Strength

Under pressure and vibration, carbide faces resist deformation.

This ensures proper face alignment, which is crucial for maintaining the thin lubricating film between seal faces.

Comparison: Carbide vs Other Seal Face Materials

| Material | Hardness | Abrasive Resistance | Thermal Conductivity | Durability in Sand |

|---|---|---|---|---|

| Carbon | Low | Poor | Moderate | Short lifespan |

| Ceramic | High | Moderate | Low | Prone to cracking |

| Tungsten Carbide | Very High | Excellent | High | Excellent performance |

| Silicon Carbide | Very High | Excellent | Very High | Outstanding in fine sand |

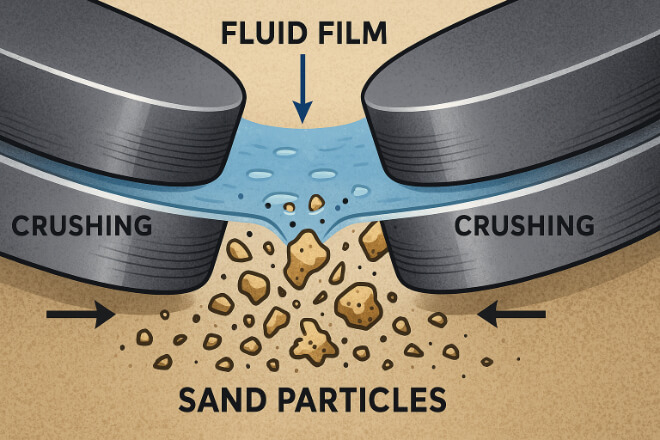

How Carbide Seal Faces Reduce Wear

When sand particles enter the sealing gap, the hard carbide faces crush or roll the particles instead of letting them embed.

This self-cleaning action helps maintain:

Smooth running surfaces

Consistent face pressure

Stable lubrication film

Additionally, WC’s dense microstructure prevents micro-pitting and maintains sealing geometry even after long operation cycles.

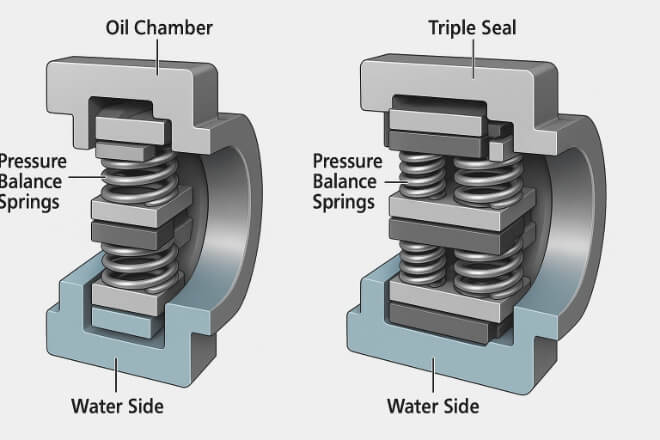

Typical Seal Stack Design for Submersible Pumps

Seal stacks use multiple mechanical seals arranged in series. The lower seal typically contacts the sand-laden water, while the upper seals protect the motor oil chamber.

1). Key Components in a Typical Stack

Lower mechanical seal: Usually tungsten carbide vs silicon carbide.

Upper mechanical seal: Carbon vs silicon carbide for oil-side lubrication.

Intermediate chamber: Filled with clean fluid to flush abrasives away.

2). Design Tip

To improve performance, engineers often use double or triple seal stacks with pressure-balancing springs to maintain even load across the faces.

Cooling and Lubrication in Sand-Laden Conditions

A small, controlled amount of lubrication fluid (water or oil) between seal faces forms a thin film that:

Reduces friction and temperature rise.

Washes away fine particles.

Maintains smooth rotation.

Carbide’s high thermal conductivity ensures that this film remains stable, preventing hot spots that could cause vaporization or dry running.

Common Failure Modes and Prevention Strategies

| Failure Type | Cause | Carbide-Based Prevention |

|---|---|---|

| Face wear | Sand abrasion | Hard carbide resists cutting and erosion |

| Thermal cracking | Excess heat buildup | High thermal conductivity disperses heat |

| Seal leakage | Face distortion or scratches | Dimensional stability under load |

| Vibration damage | Uneven wear or misalignment | Tough structure resists impact and chipping |

Field Applications of Carbide Seal Faces

Municipal water wells: Long runtime reliability despite sand intrusion.

Mining dewatering pumps: Withstand constant abrasive slurry.

Agricultural irrigation systems: Operate cleanly in high-silt groundwater.

Construction site drainage: Handle fluctuating solids concentration.

Across all cases, carbide faces provide measurable performance stability—reducing both unplanned maintenance and replacement costs.

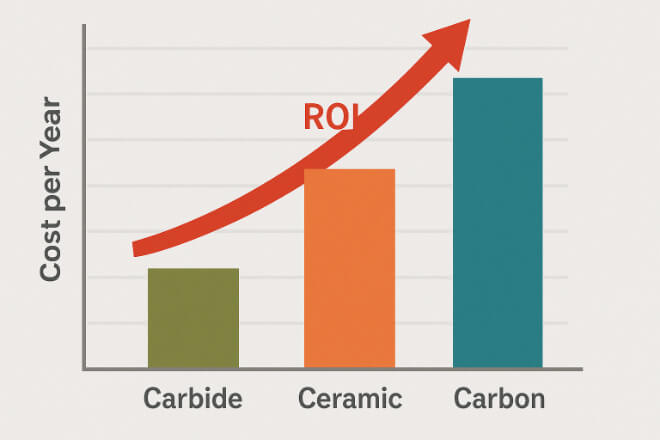

Cost and ROI Benefits

Although carbide seals cost more initially than carbon or ceramic, they deliver much longer service life.

Example ROI Analysis:

Average ceramic seal lasts 3–4 months in sandy water.

A tungsten carbide seal can exceed 12–18 months in the same conditions.

The replacement and downtime savings quickly justify the higher initial cost.

Maintenance and Inspection Recommendations

Regularly flush seal chambers to remove sediment buildup.

Monitor motor current and temperature to detect early friction issues.

Inspect carbide faces every service cycle; re-lap instead of replacing if wear is minimal.

Always use OEM-grade materials to ensure dimensional accuracy and surface finish consistency.

Conclusion

In sand-laden submersible pump systems, carbide seal faces deliver unmatched durability, thermal balance, and mechanical reliability.

Their ability to resist abrasion, handle high pressure, and maintain flatness makes them the most cost-effective solution for long-term operations in abrasive and dirty water conditions.

For decision-makers seeking to extend pump life, reduce downtime, and improve sealing reliability, choosing tungsten carbide or silicon carbide seal faces is the proven path forward.

If you want to know more details about any company, please feel free to contact us.