Tungsten carbide balls are widely used in bearings, valves, grinding, milling, and precision tools because of their extreme hardness, strength, and wear resistance.

While they offer long service life compared to steel or ceramic alternatives, decision-makers today must also ask: Are tungsten carbide balls sustainable? Can they be recycled to reduce environmental impact?

This article explores the sustainability side of tungsten carbide balls—covering recyclability, environmental benefits, and how industries can reduce costs while supporting greener practices.

Why Sustainability Matters in Carbide Materials

Global industries such as automotive, aerospace, mining, and oil & gas rely heavily on carbide balls.

At the same time, environmental regulations and corporate sustainability goals are putting pressure on supply chains.

Tungsten and cobalt, the two main ingredients of tungsten carbide, are limited natural resources.

Mining them requires energy and can impact ecosystems. Recycling and sustainable sourcing help companies:

Reduce reliance on mining raw tungsten and cobalt

Lower carbon footprint from production

Improve ESG (Environmental, Social, Governance) compliance

Show commitment to responsible sourcing

The Recyclability of Tungsten Carbide Balls

One of the strongest sustainable aspects of tungsten carbide is its high recyclability rate.

In fact, up to 95% of tungsten carbide scrap can be recovered and reused without losing its properties.

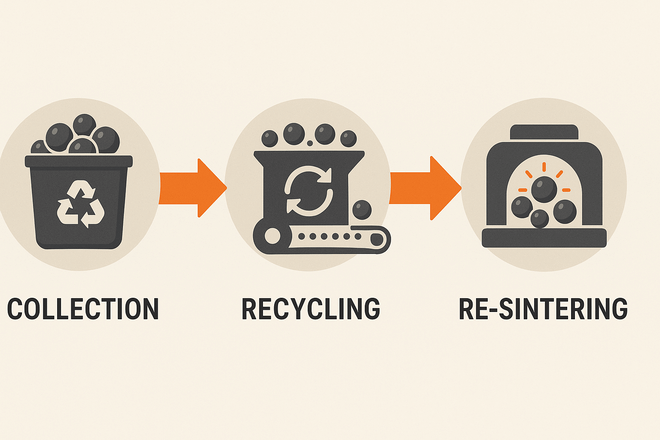

The recycling process usually includes:

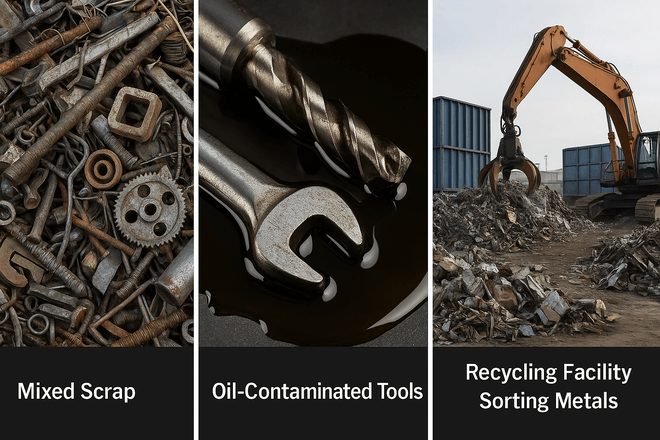

Collection – Used or worn-out carbide balls and tools are gathered.

Sorting & Cleaning – Removal of oil, coatings, or contaminants.

Chemical or Zinc Recycling – Breaking down the carbide material into tungsten powder and cobalt.

Powder Recovery – Refining the powder to meet required purity.

Re-Sintering – The recycled tungsten and cobalt are combined again to create new carbide balls.

This closed-loop system not only saves raw materials but also cuts down production energy compared to mining.

Environmental Benefits of Recycling Carbide

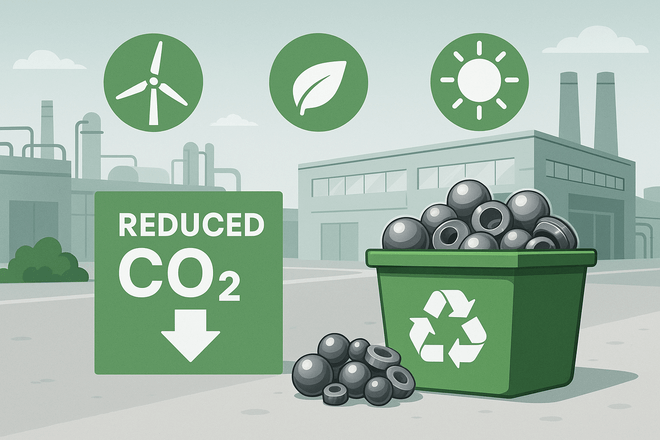

Using recycled carbide powder offers several environmental benefits:

Lower energy consumption: Recycling tungsten uses up to 70% less energy than primary extraction.

Reduced CO₂ emissions: Less mining and processing means reduced greenhouse gases.

Less waste: Scrap carbide that would otherwise end up in landfills is reintroduced into production.

Sustainable sourcing: Recycled material helps companies avoid sourcing tungsten from conflict regions.

For industries with strong sustainability goals, switching to suppliers that provide recycled tungsten carbide solutions is a competitive advantage.

Cost Advantages of Recycled Tungsten Carbide

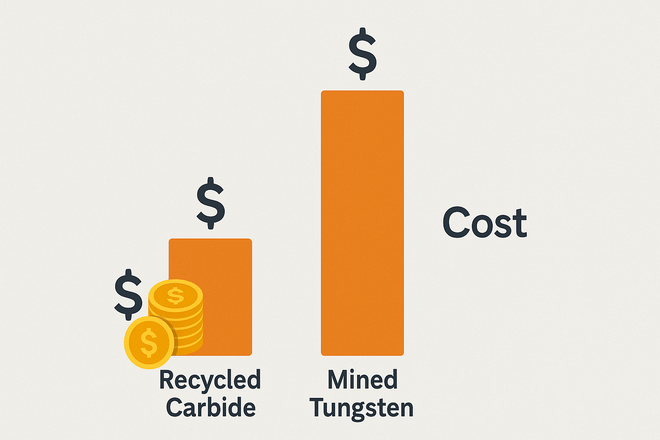

Sustainability is not just about the environment—it also makes sense financially.

Recycled carbide powder is more cost-effective than primary raw materials.

Stable supply reduces risk from price fluctuations in tungsten markets.

Companies can set up scrap buyback programs, turning waste carbide balls into financial return.

For decision-makers, this means lower cost per part, improved predictability, and better resource efficiency.

Applications for Recycled Carbide Balls

Recycled tungsten carbide balls can be used in most of the same applications as new carbide:

| Application | Recycled Carbide Ball Use | Benefits |

|---|---|---|

| Bearings | Recycled balls in industrial bearings | Cost savings with equal durability |

| Valves & Pumps | Fluid control systems in oil & gas | Resistance to wear, corrosion, and pressure |

| Grinding Media | Ball mills in mining and cement | Efficient milling with long service life |

| Precision Tools | Measuring devices and ball screws | Maintains dimensional accuracy and strength |

This proves that recycled carbide balls are not lower quality, but an equal substitute that supports circular economy models.

Challenges in Recycling Tungsten Carbide Balls

While recyclable, there are still hurdles:

Collection logistics: Not all companies have systems for retrieving used carbide balls.

Contamination: Oil, coatings, or mixed metals can complicate recycling.

Initial cost: Setting up recycling facilities requires investment.

Still, many suppliers now offer recycling programs, making it easier for industries to send back scrap for processing.

How Companies Can Support Sustainable Use

Decision-makers looking to integrate sustainability should:

Partner with suppliers offering recycled carbide materials.

Start a scrap return program with machine shops and plants.

Ask for certification of recycled content in purchased carbide balls.

Factor in sustainability as part of supplier evaluation criteria.

This approach ensures both operational efficiency and compliance with global sustainability standards.

Final Thoughts

Tungsten carbide balls already bring superior performance, longer lifespan, and cost benefits compared to steel or ceramic.

By embracing recycling and sustainable sourcing, industries can also reduce environmental impact and strengthen supply chain resilience.

For decision-makers, the choice is clear: tungsten carbide balls are not just a performance solution—they are a sustainable investment for the future.

If you want to know more details about any company, please feel free to contact us.