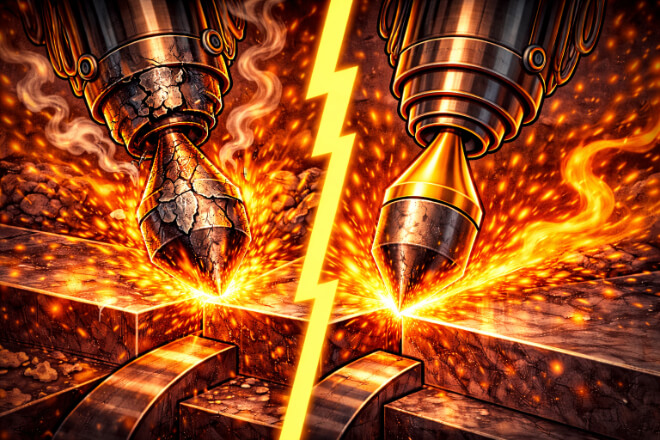

Many industrial cutting and drilling operations work under extreme temperature conditions. High heat or sudden temperature changes can quickly damage standard tool materials, leading to fast wear, tool failure, and high costs.

Tungsten carbide tips are widely used in these harsh environments because they keep their strength and cutting ability even when temperatures rise or drop sharply.

This article explains how tungsten carbide tips perform in extreme temperature applications and why they are a smart choice for decision-makers who care about tool life, efficiency, and cost control.

1. Understanding Extreme Temperature Applications

Extreme temperature applications refer to operations where tools face very high heat, very low temperatures, or frequent thermal shock.

These conditions are common in industries such as oil and gas, mining, aerospace, metalworking, and heavy manufacturing.

High temperatures usually come from:

High-speed cutting or drilling

Hard or abrasive materials

Continuous operation without long cooling breaks

Low temperatures and thermal shock often occur when:

Tools move between hot cutting zones and cooling fluids

Equipment operates outdoors in cold environments

Rapid heating and cooling cycles happen during production

In these conditions, many tool materials soften, crack, or lose their cutting edge.

Tungsten carbide tips are designed to handle these challenges much better than standard steel or alloy tools.

2. Why Temperature Resistance Matters for Cutting Tools

Temperature resistance plays a major role in tool performance and safety. When a tool cannot handle heat or cold properly, several problems appear quickly.

Common issues caused by poor temperature resistance include:

Loss of hardness at high temperatures

Cracking due to thermal shock

Fast edge wear and dulling

Sudden tool breakage

These problems increase downtime, raise maintenance costs, and reduce production efficiency.

For decision-makers, temperature-resistant tools are not just a technical choice but also a cost and reliability decision.

Tungsten carbide tips offer stable performance across a wide temperature range, helping avoid these risks.

3. How Tungsten Carbide Tips Perform at High Temperatures

One of the biggest advantages of tungsten carbide tips is their ability to maintain hardness at high temperatures.

Unlike many metals, tungsten carbide does not soften easily when heat builds up during cutting or drilling.

Key high-temperature benefits include:

Heat stability: Tungsten carbide keeps its hardness even at very high cutting temperatures.

Edge retention: The cutting edge stays sharp longer, improving cutting accuracy.

Lower deformation risk: The tool shape remains stable, even during long cutting cycles.

Because of these properties, tungsten carbide tips are commonly used in high-speed machining, hot metal cutting, and heavy drilling where heat is constant and unavoidable.

4. Performance of Tungsten Carbide Tips in Low-Temperature Environments

Extreme temperature applications are not limited to high heat. In cold or outdoor environments, tools can become brittle and crack more easily.

Tungsten carbide tips perform well in these situations when properly designed and bonded.

Benefits in low-temperature conditions include:

Good structural stability: Tungsten carbide resists cracking caused by cold exposure.

Consistent cutting behavior: Cutting performance remains stable even in cold starts.

Reduced risk of sudden failure: Strong bonding and material structure prevent tip breakage.

This makes tungsten carbide tips suitable for mining, oil exploration, and construction work in cold climates.

5. Resistance to Thermal Shock and Temperature Cycling

Thermal shock happens when tools experience rapid temperature changes, such as moving from hot cutting zones into coolant or air.

This is one of the most damaging conditions for cutting tools.

Tungsten carbide tips handle thermal shock better because:

They have low thermal expansion compared to steel

Their structure resists sudden stress changes

High-quality bonding prevents tip separation

This resistance helps reduce micro-cracks, edge chipping, and early tool failure, especially in CNC machining and drilling operations with frequent cooling cycles.

6. Tool Life Improvement in Extreme Temperature Applications

Tool life is a major concern for decision-makers. Extreme temperatures usually shorten tool life, but tungsten carbide tips help reverse this trend.

How tungsten carbide tips extend tool life:

Less wear at high temperatures

Lower risk of cracking from temperature changes

Stable cutting edges over long production runs

Longer tool life means fewer tool changes, less machine downtime, and more predictable production planning.

Over time, this leads to better productivity and lower operating costs.

7. Typical Applications Using Tungsten Carbide Tips at Extreme Temperatures

Tungsten carbide tips are widely used in industries where temperature control is difficult or impossible.

Common applications include:

Oil and gas drilling: High friction and deep drilling generate extreme heat.

Metal cutting and forging: Hot metals require heat-resistant cutting tools.

Aerospace machining: High-speed cutting of heat-resistant alloys.

Mining operations: Constant friction, impact, and temperature variation.

In all these applications, tungsten carbide tips deliver reliable performance where other materials fail.

8. Cost Benefits of Using Tungsten Carbide Tips in Extreme Temperatures

Although tungsten carbide tips cost more upfront than standard tools, they offer clear long-term savings in extreme temperature environments.

Key cost advantages include:

Fewer tool replacements

Reduced downtime and labor costs

More consistent production quality

Lower risk of unexpected tool failure

For decision-makers, the total cost of ownership is often much lower when tungsten carbide tips are used in demanding temperature conditions.

Conclusion

Extreme temperature applications place heavy demands on cutting and drilling tools.

Tungsten carbide tips stand out because they maintain hardness, resist thermal shock, and deliver stable performance in both high-heat and low-temperature environments.

By extending tool life, improving reliability, and reducing downtime, tungsten carbide tips offer clear technical and economic benefits.

For industries working under extreme temperature conditions, they are a proven solution for better performance and long-term efficiency.

If you want to know more details about any company, please feel free to contact us.