In many industries, decision-makers face the same challenge: how to balance upfront cost with long-term value. Equipment parts wear out, machines stop working, and downtime increases cost.

To solve this, many companies now turn to tungsten carbide. While the first investment may look higher compared to steel or other materials, the long-term savings and performance benefits are clear.

This article explains why investing in tungsten carbide brings real value for industries such as mining, oil & gas, metal forming, paper, packaging, and woodworking.

We will look at the financial, technical, and strategic reasons why tungsten carbide is a smart choice for companies that want better efficiency, lower cost, and stronger competitiveness.

What Is Tungsten Carbide?

Tungsten carbide is a material made by combining tungsten powder with a binder metal like cobalt.

The result is an extremely hard, dense, and wear-resistant compound.

Key properties:

Hardness close to diamond

High wear resistance and abrasion

Ability to handle heat and pressure

Longer service life compared to steel

These properties make tungsten carbide the material of choice for wear parts, cutting tools, drills, dies, valve seats, seals, and nozzles.

The Cost Challenge in Industry

Every decision-maker understands the hidden cost of downtime and frequent replacements. Some common challenges include:

Frequent tool changes slowing production.

High labor and maintenance cost from replacing worn parts.

Unplanned machine stoppages that cause lost output.

Lower product quality when tools wear too quickly.

While cheaper parts may seem attractive at first, they usually bring higher costs in the long term. Tungsten carbide helps companies break this cycle.

Why Tungsten Carbide Brings Long-Term Value

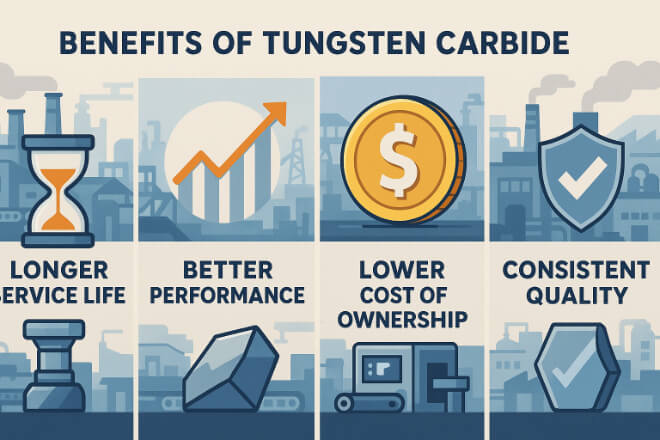

1). Longer Service Life

Carbide parts last 3–10 times longer than standard steel parts. This means:

Fewer replacements.

Less downtime.

Lower inventory cost.

2). Better Performance Under Stress

In mining drills, stamping dies, or valve systems, carbide can handle high pressure, temperature, and friction without breaking down.

3). Lower Total Cost of Ownership

Even if carbide parts cost more upfront, the lifetime cost is lower because they do not need frequent replacement.

4). Consistent Quality

Stable tool performance reduces product defects. Consistency improves customer trust and avoids costly rework.

Case Comparison: Steel vs. Tungsten Carbide

| Factor | Steel Parts | Tungsten Carbide Parts |

|---|---|---|

| Initial Cost | Low | High |

| Service Life | 1–3 months | 6–18 months |

| Replacement Frequency | Very high | Low |

| Downtime Impact | High | Low |

| Total Long-Term Cost | High | Low |

This table shows that although carbide parts need more investment at the start, they save more money in the long run.

Industry Applications of Tungsten Carbide

1). Mining and Construction

Carbide drill bits last longer in hard rock drilling.

Reduced tool changes lower downtime underground.

2). Oil & Gas

Carbide valve seats and seals handle abrasive fluids.

Longer equipment life reduces failure risk.

3). Metal Forming and Stamping

Carbide dies resist deformation.

High precision reduces rework.

4). Woodworking and Paper

Carbide blades and knives stay sharper longer.

Companies save on sharpening and replacements.

5). Packaging Machinery

Carbide wear parts keep machines running smoothly.

Helps maintain high output for fast-moving industries.

Strategic Benefits for Decision-Makers

Cost Reduction: Lower lifetime cost compared to steel.

Efficiency: More uptime, less maintenance.

Predictability: Fewer unexpected failures.

Stronger Competitiveness: Ability to meet customer demand consistently.

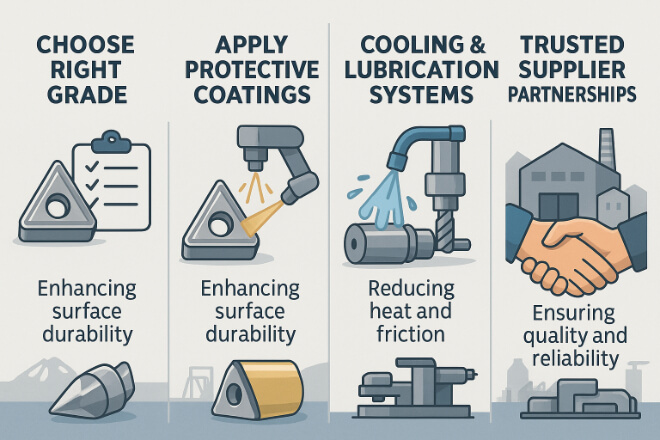

How to Maximize the Value of Tungsten Carbide

1). Choose the Right Grade

Different grades of carbide suit different needs. Work with a supplier to select the best fit.

2). Use Coatings

Coatings like TiN, TiCN, or TiAlN add extra protection.

3). Maintain Proper Cooling and Lubrication

This extends part life and keeps tools running smoothly.

4). Work with Trusted Suppliers

Consistency in carbide quality is essential for long-term results.

Return on Investment (ROI) Perspective

| Year | Steel Wear Parts Cost | Tungsten Carbide Wear Parts Cost |

|---|---|---|

| Year 1 | $50,000 | $70,000 |

| Year 2 | $45,000 | $20,000 |

| Year 3 | $55,000 | $25,000 |

| Total (3 Years) | $150,000 | $115,000 |

This shows that even though tungsten carbide requires higher spending in the first year, the three-year total cost is much lower.

Conclusion

For industries that rely on heavy machinery and high production output, tungsten carbide is not just a material—it is a long-term investment.

By reducing downtime, extending part life, and lowering total costs, it delivers both financial and strategic advantages.

For decision-makers, the message is clear: investing in tungsten carbide today means higher efficiency, lower risk, and stronger profitability in the future.

If you want to know more details about any company, please feel free to contact us.