Tungsten carbide cutting tools are widely used in industries like metalworking, woodworking, aerospace, and mold manufacturing. They are strong, wear-resistant, and can cut hard materials. But even these tools can wear out or break over time.

This is where tool coatings come in. A good coating helps extend the tool’s life, improve performance, and reduce costs. In this article, we explain how coatings work, what types of coatings are used, and why they are important for getting the best results from your tungsten carbide cutting tools.

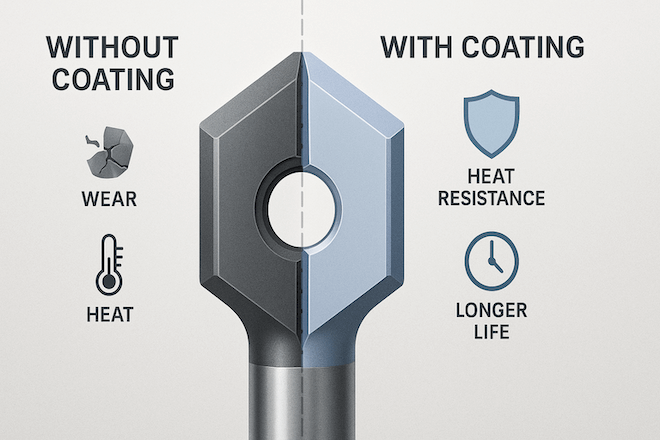

Why Coatings Are Important for Tungsten Carbide Tools

Even though tungsten carbide is already a hard material, cutting tools made from it still face challenges:

Friction and heat when cutting metal

Wear and tear over long use

Corrosion from coolant or chemicals

Built-up edges from sticky materials

A coating acts like a shield. It protects the surface of the tool and helps it last longer. Coated tools also cut more smoothly and with better results.

Learn more about how carbide works here:

👉 Tungsten Carbide Technical Glossary

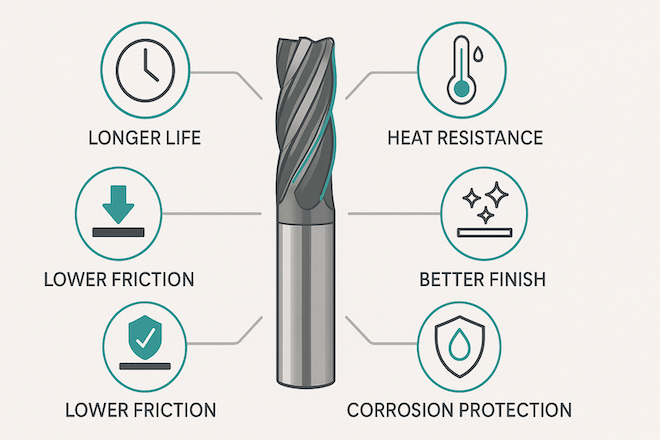

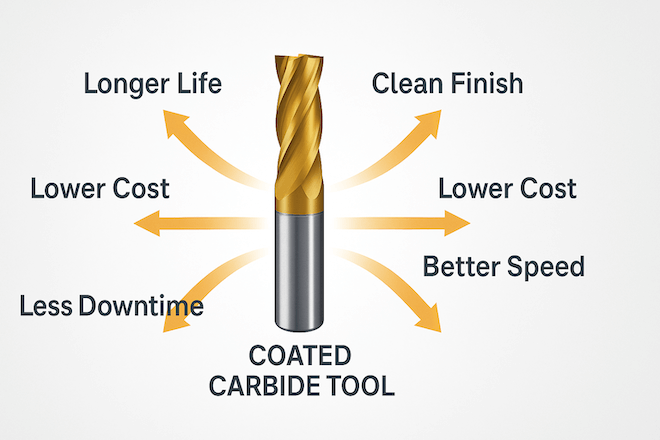

Main Benefits of Using Coated Carbide Tools

Longer Tool Life

Coatings reduce wear and make the tool edge last longer.

Tools stay sharp for more cuts.

Better Heat Resistance

Coated tools can handle higher cutting speeds.

Less chance of overheating or softening.

Reduced Friction

Cutting is smoother, especially on sticky metals like aluminum.

Less force is needed, which saves energy.

Improved Surface Finish

The part being cut looks cleaner and smoother.

Less need for extra finishing steps.

Protection Against Corrosion

Coating protects against chemical damage from coolants or fluids.

Interested in coated tools?

👉 Carbide Cutting Tools by Retop

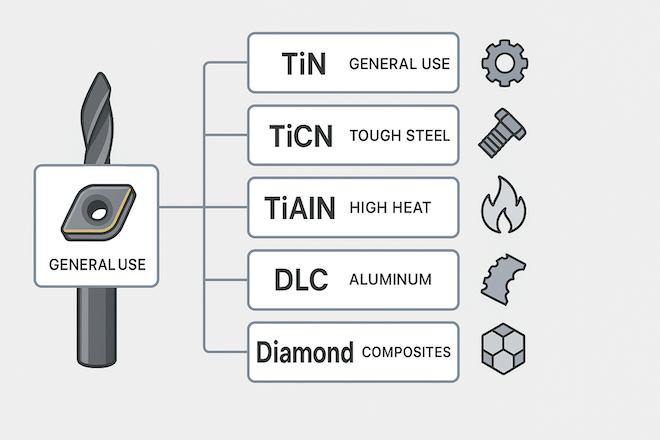

Popular Coatings for Carbide Cutting Tools

There are many types of coatings available. Here are the most common ones used for tungsten carbide tools:

1. TiN (Titanium Nitride)

Gold color

Good for general use

Reduces friction and adds basic wear resistance

Popular in woodworking and light metal cutting

2. TiCN (Titanium Carbonitride)

Gray-blue color

Harder and tougher than TiN

Better for stainless steel and tough materials

Less risk of edge chipping

3. TiAlN / AlTiN (Titanium Aluminum Nitride)

Dark gray or black

Great for high-speed machining

Strong heat resistance and oxidation protection

Ideal for dry cutting or minimal coolant use

4. DLC (Diamond-Like Carbon)

Very low friction

Best for aluminum, plastic, and non-ferrous materials

Avoid using on hard steels

5. CVD Diamond Coating

True diamond coating

Excellent for cutting composites, carbon fiber, ceramics

Very hard, but brittle—best in non-impact use

Want a full coating guide?

👉 Tungsten Carbide Coating Guide

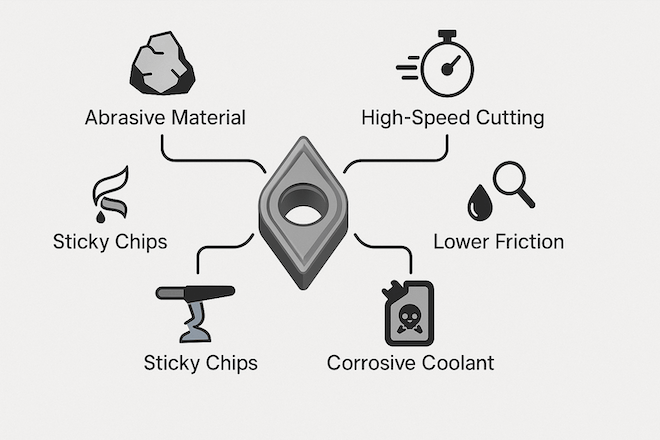

When Should You Use Coated Tools?

Not every job needs a coated tool. But for high-performance cutting, coatings make a big difference. You should use coatings when:

Cutting hard or abrasive materials like stainless steel, cast iron, or titanium

Running tools at high speed or dry machining

Working with corrosive coolants or fluids

Cutting sticky or soft materials that cause built-up edges

You need a long tool life and clean surface finish

For special jobs, you may need custom coated carbide tools.

👉 Contact Retop for Custom Carbide Tooling

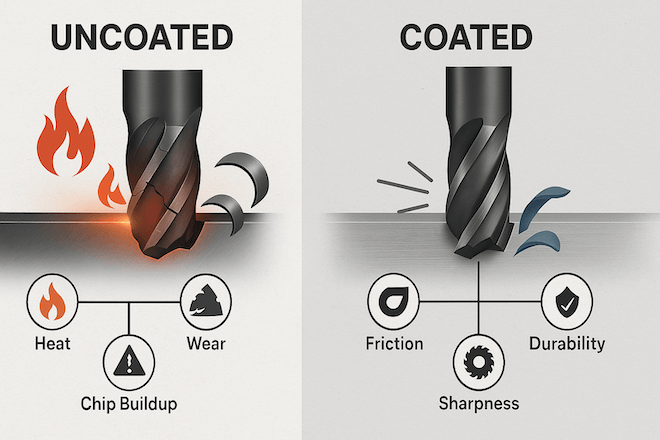

Coating vs. No Coating: What’s the Difference?

Let’s compare how coated and uncoated tools perform:

| Feature | Uncoated Tool | Coated Tool |

|---|---|---|

| Tool Life | Shorter | Much longer |

| Cutting Speed | Lower | Higher |

| Heat Resistance | Moderate | High |

| Wear Resistance | Medium | Excellent |

| Surface Finish Quality | Inconsistent | Smooth and clean |

| Cost-Effectiveness | Lower initial cost | Lower cost per part over time |

Coatings increase upfront price but save you money long-term.

Retop’s Approach to Coated Carbide Tools

At Retop, we understand the value of high-quality coatings. That’s why our carbide tools go through strict quality control and offer multiple coating options.

Why choose Retop?

✅ 14+ years of experience in tungsten carbide manufacturing

✅ Custom carbide tools and coatings for your application

✅ Export to 50+ countries

✅ ISO 9001 certified quality

✅ Professional team for R&D and coating upgrades

Explore all coated tools at:

👉 www.retopz.com

Tips for Choosing the Right Coating

Here are some quick tips to help you pick the right coating:

TiN – Good start for light jobs or woodworking

TiCN – Better for tough materials and long life

TiAlN/AlTiN – Best for heat, high-speed, and dry cutting

DLC – Excellent for aluminum and plastic

CVD Diamond – For carbon fiber and composites

Not sure which to choose? Ask Retop.

Summary: What You Gain from Using Coated Carbide Tools

Longer life for each tool

More cuts per sharpening cycle

Cleaner and faster machining

Better product quality

Lower costs over time

Less downtime for tool changes

With the right coating, your tungsten carbide cutting tools will perform at their best.

Final Thoughts

Coatings are not just an extra feature—they are a smart investment. They help you save time, money, and improve the quality of your work. If you’re not using coated tungsten carbide tools yet, now is a great time to upgrade.

Work with a trusted supplier like Retop to get the right tools, the right coatings, and the best results.